Preparation method and application of nanowire-like nickel-based complex electrode material

A technology of electrode materials and nanowires, which is applied in the field of preparation of nanowire-shaped nickel-based complex electrode materials, to achieve the effects of simple experimental operation, stable rate characteristics, and high specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

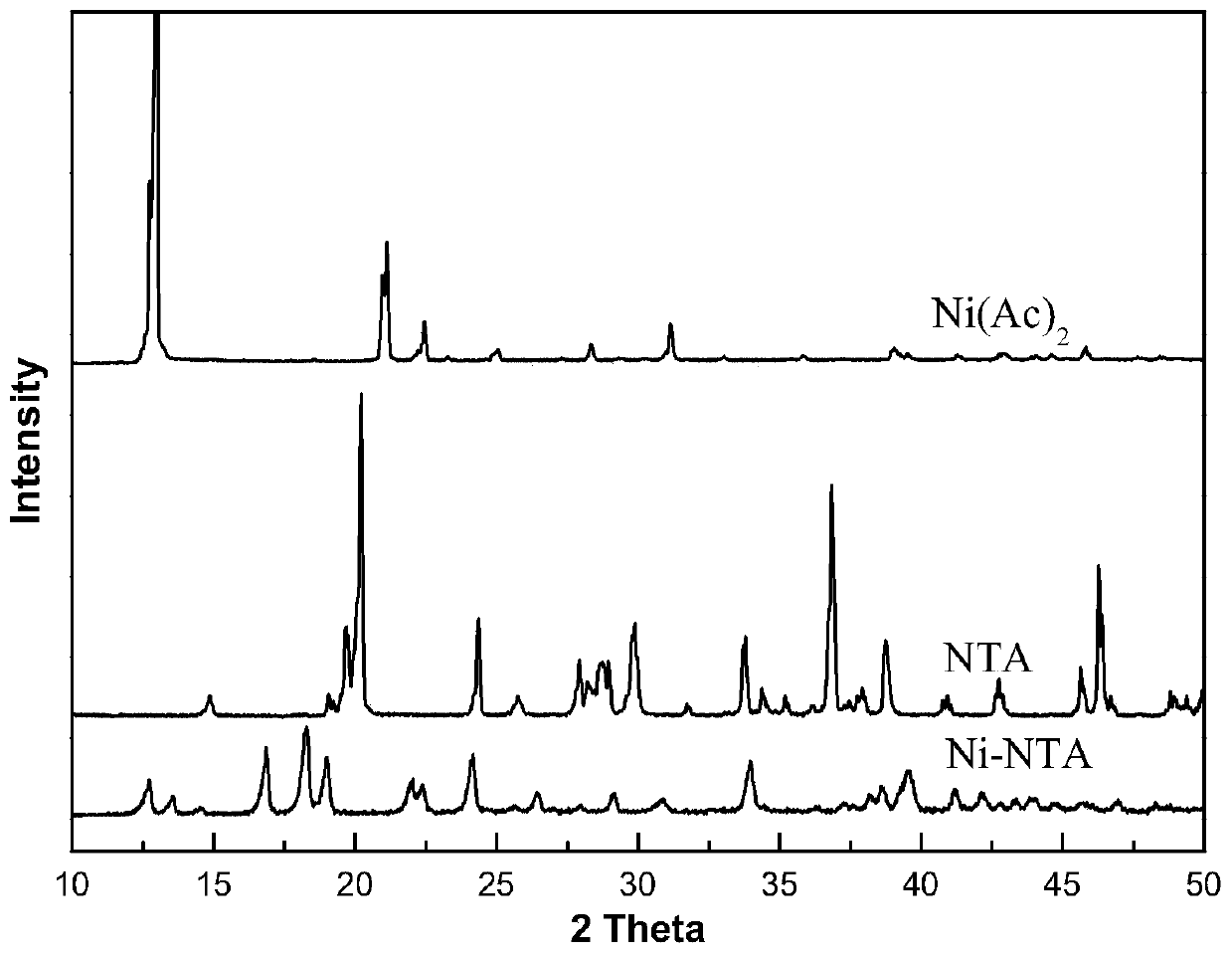

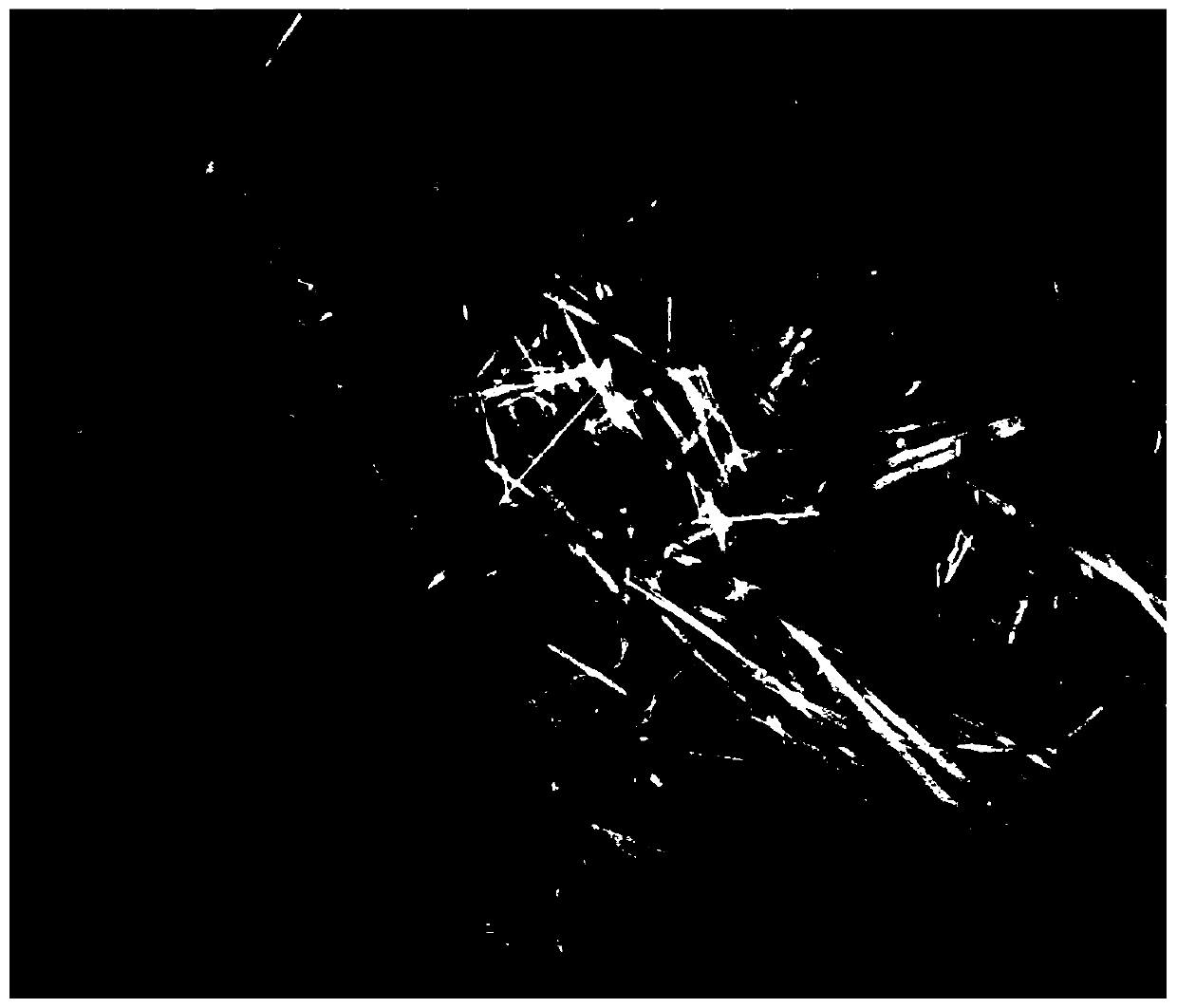

[0034] Example 1 A nanowire-shaped nickel-based complex electrode material

[0035] The preparation method is as follows: weigh 2 mmol of nickel acetate and 0.4 g of nitrilotriacetic acid and dissolve them in 7.5 ml of deionized water, add 7.5 ml of isopropanol into the above solution and stir for 30 minutes, transfer the above mixed solution to a In a reaction kettle lined with vinyl fluoride, heat at an oven temperature of 180°C for 24h, cool naturally to room temperature, centrifuge the reaction product and wash it with deionized water and absolute ethanol for 8 times, and then dry it at 40°C for 12h to obtain It has nanowire-like nickel-based complex electrode materials.

[0036]Mix the nickel-based complex electrode material obtained above with the conductive agent acetylene black and the binder PTFE at a mass ratio of 7.5:1.5:1, and uniformly disperse in absolute ethanol to form a slurry, and apply the slurry evenly on an area of 1cm 2 On the nickel foam substrate, th...

Embodiment 2

[0042] Example 2 A nanowire-shaped nickel-based complex electrode material

[0043] Its preparation method is: weigh 1mmol of nickel nitrate and 0.01g of nitrilotriacetic acid dissolved in 12ml of deionized water, measure 3ml of isopropanol, add it to the above solution and stir for 30min to obtain a mixed solution, transfer the above mixed solution to a In a reaction kettle lined with tetrafluoroethylene, heat at an oven temperature of 150°C for 6h, cool naturally to room temperature, centrifuge the reaction product, wash with deionized water and absolute ethanol 8 times, and then dry at 40°C After 12 hours, the nanowire-shaped nickel-based complex electrode material was obtained.

Embodiment 3

[0044] Example 3 A nanowire-shaped nickel-based complex electrode material

[0045] The preparation method is as follows: weigh 4 mmol of nickel sulfate and 0.6 g of nitrilotriacetic acid and dissolve them in 9 ml of deionized water, add 6 ml of isopropanol into the above solution and stir for 30 minutes, transfer the above mixed solution to a tank with polytetrafluoroethylene In a lined reactor, heat at an oven temperature of 150°C for 24h, cool naturally to room temperature, centrifuge the reaction product, wash with deionized water and absolute ethanol for 8 times, and then dry at 40°C for 12h to obtain Nanowire-shaped nickel-based complex electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com