A method for determining the position of the oil outlet of a double rectangular cavity hydrostatic sliding bearing

A static pressure sliding bearing, a technology to determine the method, applied to bearings, shafts and bearings, mechanical equipment, etc., can solve the problem of uneven flow at the sealing edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

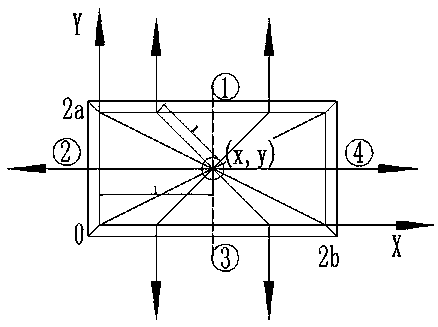

[0021] The invention aims to solve the problem of unbalanced flow distribution of each oil seal edge caused by the rotation of the turntable, so a method for determining the position of the oil outlet of the hydrostatic sliding bearing with double rectangular cavities is proposed.

[0022] A method for determining the position of the oil outlet of a hydrostatic sliding bearing with double rectangular cavities is realized by the following steps:

[0023] Step A, establishing a single rectangular cavity to simplify the flow velocity vector.

[0024] The flow velocity direction of each oil sealing edge is perpendicular to each oil sealing edge, and its size is inversely proportional to the distance l between the oil outlet and the oil sealing edge.

[0025] Step B: Establish the rotational speed vector of the turntable, and synthesize it with the hydraulic oil flow velocity vector to obtain the resultant velocity.

[0026] It can be known from fluid kinematics that there is a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com