Travel motor delay brake valve and travel motor

A technology for traveling motors and brake valves, which is applied in the fields of hydraulic pressure and machinery, and can solve problems such as delay time mismatch, heat generation, friction plate sintering, etc., and achieve the effects of solving friction plate sintering, improving reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

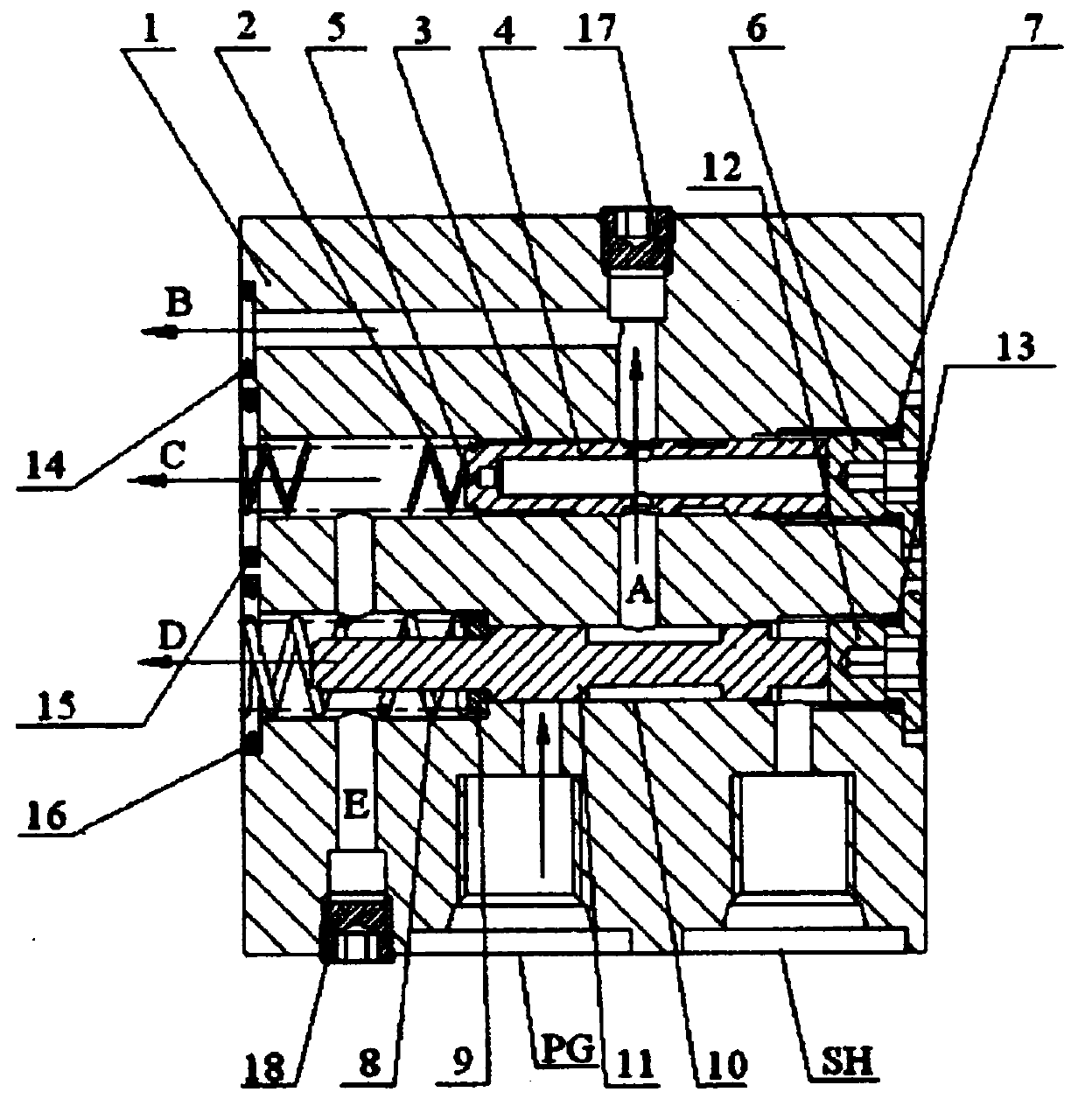

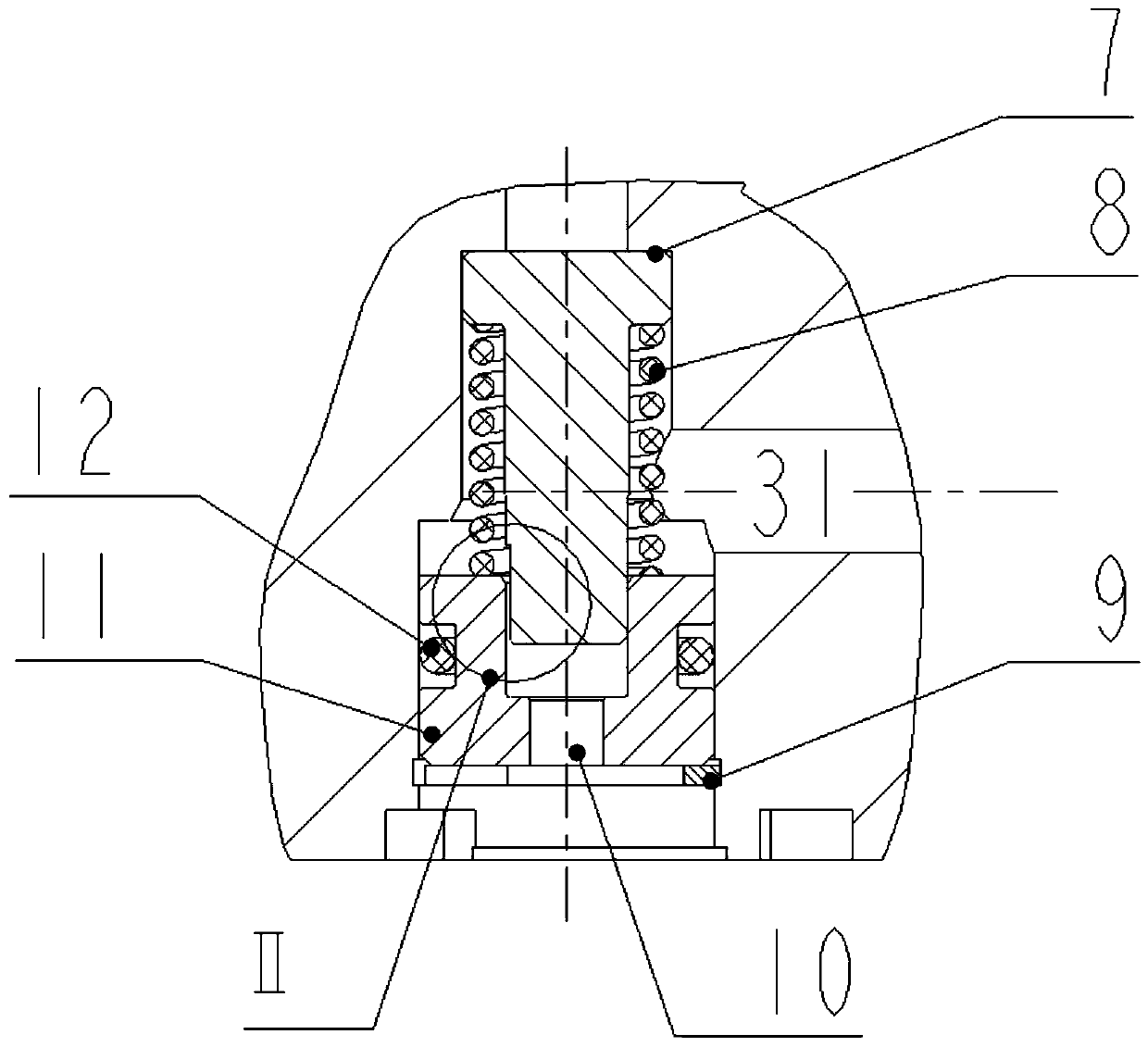

[0041] The new hydraulic travel motor delay brake valve of the present invention adopts Figure 2 to Figure 4 In the shown structure, the delay brake valve 3 is built in the travel motor end cover 1, and the delay brake valve 3 is composed of a valve core 7, a return spring 8, a retaining ring 9, a valve seat 11 and an O-ring 12. One end of the valve core 7 is inserted into the valve seat 11 and can move relative to the valve seat. The return spring 8 is sleeved on the valve core 7 and clamped by the valve core 7 and the valve seat 11 . A damping groove 71 is opened on the valve core 7; an oil drain hole 10 that can lead to the motor housing drain cavity is opened in the groove of the valve seat facing the valve core; when the valve core is in the first relative position relative to the valve seat, the damping The groove is connected with the bypass oil passage, and the oil in the bypass oil passage flows to the oil drain hole through the damping groove; when the valve core is...

Embodiment 2

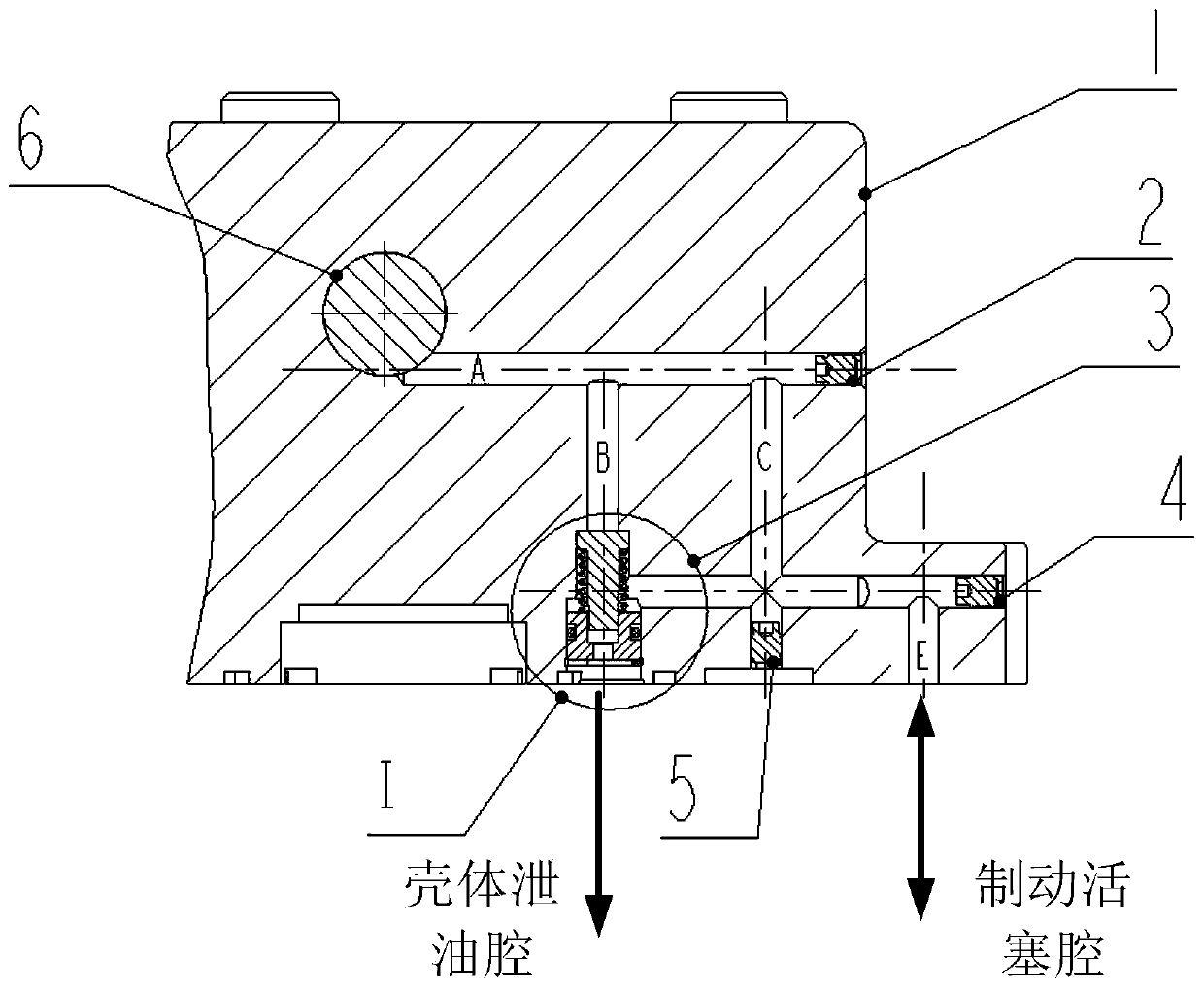

[0045] On the basis of Example 1, combined with Figure 2 to Figure 4 , in this embodiment, for the convenience of processing, the bypass oil passage can be specifically set as several oil passages, including oil passages A, B, C, D, E, and an auxetic plug 2 is used for the external unused ports , 4, 5 are blocked.

[0046]One end of the oil passage A is connected to the high-pressure chamber of the balance valve 6, and the other end is sealed by the auxetic plug 2. One end of the oil passage B is connected with the oil passage A, and the other end is connected with the delay brake valve 3 . Oil passage C communicates with oil passage A and delay brake valve spring chamber 31 respectively, and the bottom of oil passage C is sealed by an auxetic plug 5 . Oil passage D is respectively connected with oil passage C, oil passage E and delay brake valve spring chamber 31, the right end of oil passage D is sealed by auxetic plug 4, one end of oil passage E is connected with oil pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com