Internal combustion engine and valve drive unit thereof

A technology for internal combustion engines and driving devices, applied to engine components, machines/engines, valve devices, etc., can solve problems such as large construction space, high structure, and heavy weight, and achieve low structural cost, reduced weight, and simple and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

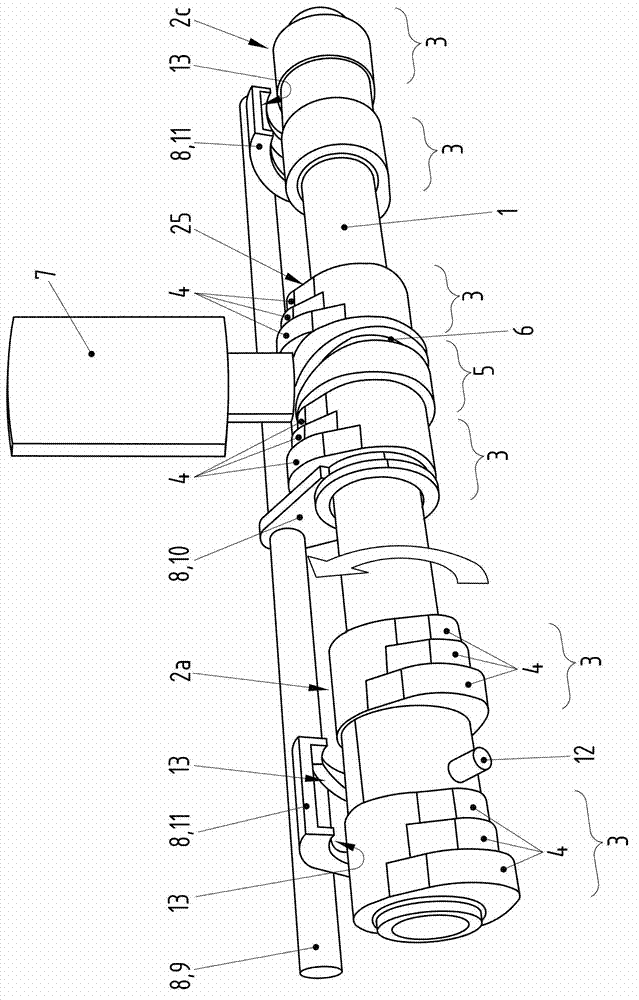

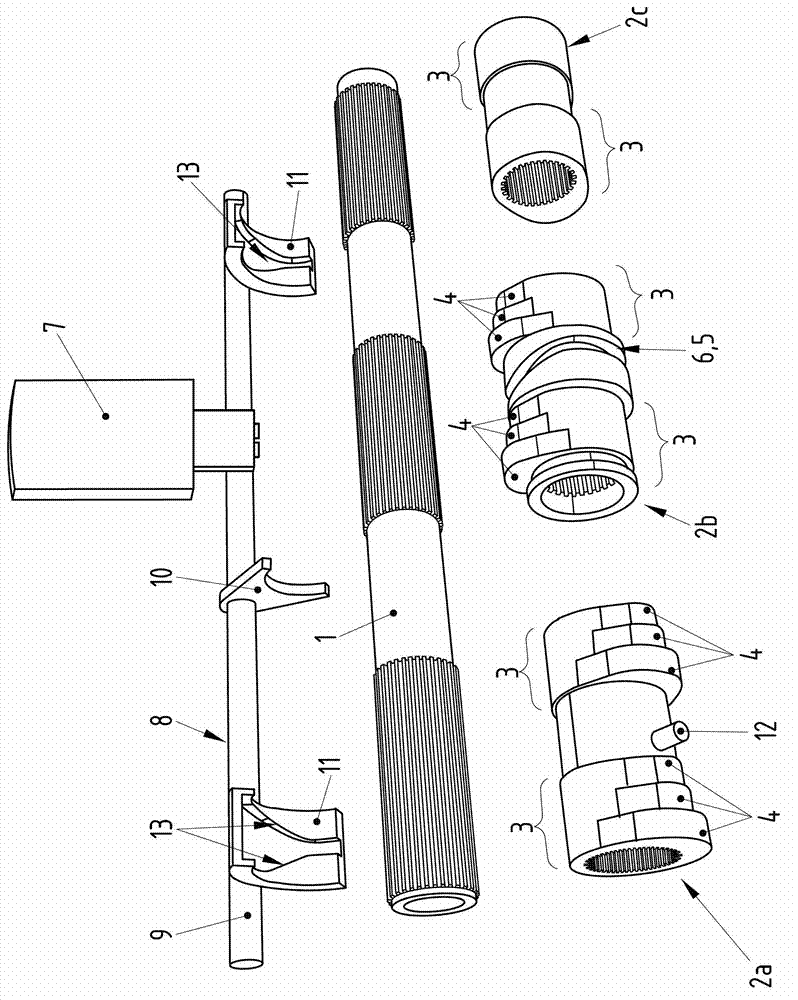

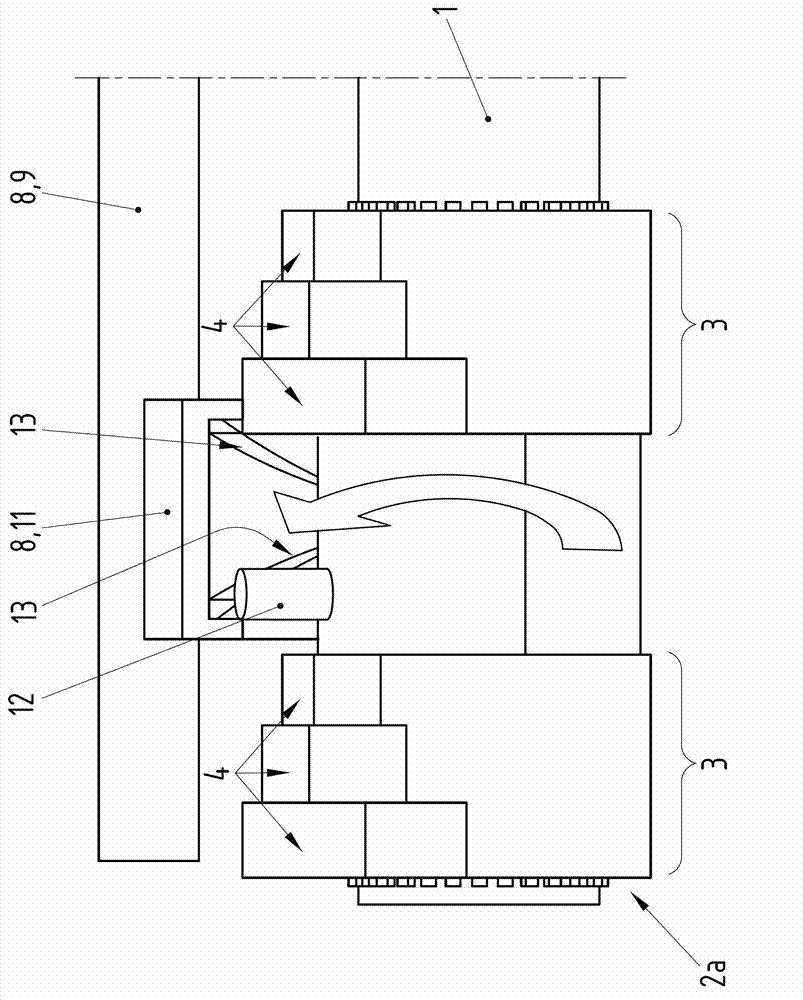

[0024] Figure 1 to Figure 8 Various views and details of a first variant according to the invention of a valve drive of an internal combustion engine are shown.

[0025] then Figure 1 to Figure 8 The valve drive comprises a camshaft 1 which is supported via a not shown camshaft bearing on a not shown internal combustion engine cylinder head. A cylinder head of this type can consist of a cylinder head lower part and a camshaft housing, wherein the cylinder head lower part and the camshaft housing can also be embodied in one piece.

[0026] exist Figure 1 to Figure 8 The camshaft 1 shown in is preferably an intake camshaft, which is used to control the likewise not shown intake valves of the internal combustion engine with a roller lever not shown. There is a not shown exhaust camshaft for controlling the not shown internal combustion engine exhaust valves. The intake and exhaust valves of an internal combustion engine are the gas exchange valves of the internal combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com