A highly stable tailings dam and its construction method

A high-stability, tailings dam technology, used in construction, filling, building components, etc., can solve problems such as unfavorable long-term operation of tailings ponds, structural instability, safety problems, etc., and achieve long-term safe operation and maintain stability. , the effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The construction method of the tailings dam flexible damping system includes the following steps:

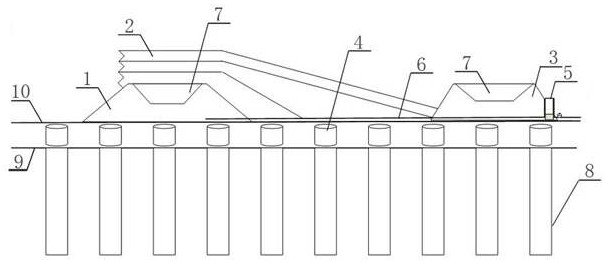

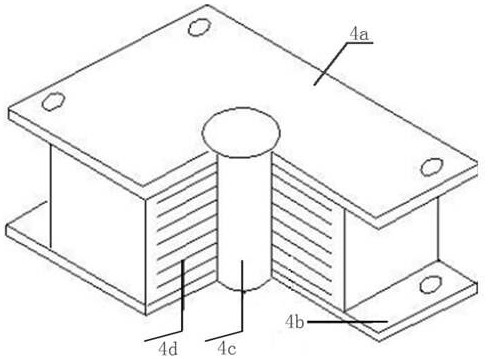

[0047] S1. First, flatten and reinforce the foundation and embed support columns 8 so that the support columns 8 are evenly distributed in the tailings dam area, and then lay the first layer of anti-seepage steel plates 9 on the support columns 8, and then lay the first layer of anti-seepage steel plates Install the shock absorbing support 4 on the 9, and the support column 8 corresponds to the shock absorbing support 4 one by one, and then lay the second layer of anti-seepage steel plate 10 on the shock absorbing support 4;

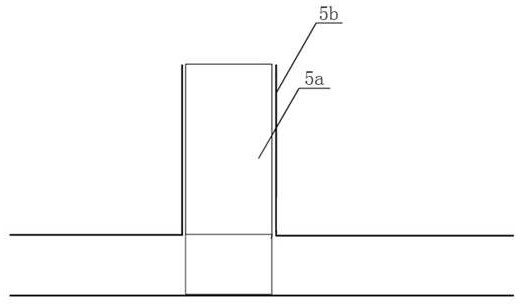

[0048] S2. On the second layer of anti-seepage steel plate 10, establish the initial dam 1 and the downstream retaining dike 3 according to the centerline method. into the permeable reaction wall 5, and connect the seepage drainage pipe 6 of the initial dam 1, the seepage drainage pipe 6 of the downstream retaining embankment 3, and the permeable re...

Embodiment 2

[0051] The construction method of the tailings dam flexible damping system includes the following steps:

[0052] S1. First level and reinforce the foundation and embed support columns 8 so that the support columns 8 are evenly distributed in the tailings dam area. The diameter of the support columns 8 is 50 cm and the height is 3 m. The distance between them is 1.5m, and the height difference between two adjacent support columns 8 is less than 0.5mm. Then the first layer of anti-seepage steel plate 9 is laid on the support column 8, and then the shock-absorbing support 4 is installed on the first layer of anti-seepage steel plate 9. , and the support column 8 corresponds to the shock absorber 4 one by one, and then the second layer of anti-seepage steel plate 10 is laid on the shock absorber 4;

[0053] S2. On the second layer of anti-seepage steel plate 10, establish the initial dam 1 and the downstream retaining dike 3 according to the centerline method. into the permeable...

Embodiment 3

[0056] The construction method of the tailings dam flexible damping system includes the following steps:

[0057] S1. First level and reinforce the foundation and embed support columns 8 so that the support columns 8 are evenly distributed in the tailings dam area. The diameter of the support columns 8 is 100 cm and the height is 5 m. The distance between them is 2.5m, and the height difference between two adjacent support columns 8 is less than 0.5mm. Then the first layer of anti-seepage steel plate 9 is laid on the support column 8, and then the shock-absorbing support 4 is installed on the first layer of anti-seepage steel plate 9. , and the support column 8 corresponds to the shock absorber 4 one by one, and then the second layer of anti-seepage steel plate 10 is laid on the shock absorber 4;

[0058] S2. On the second layer of anti-seepage steel plate 10, establish the initial dam 1 and the downstream retaining dike 3 according to the centerline method. into the permeabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com