A kind of ultra-high-strength heat-resistant aluminum alloy and its preparation method

An ultra-high-strength, aluminum alloy technology that is applied in the field of aluminum alloys to achieve the effects of improving the stability of the structure and performance, improving the overall performance of the alloy, and eliminating casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

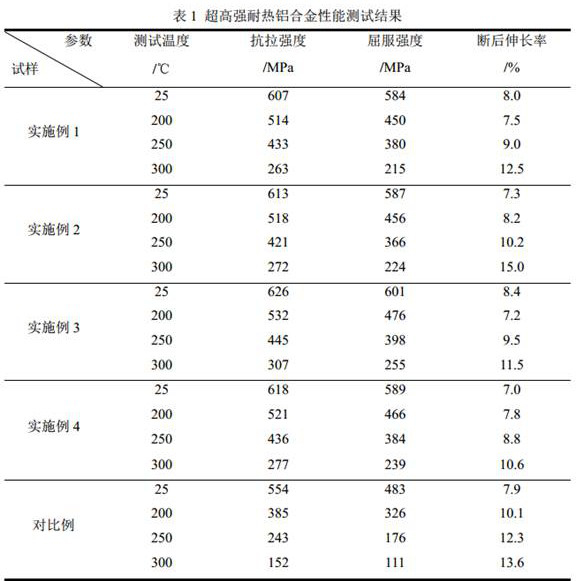

Examples

Embodiment 1

[0024] An ultra-high-strength heat-resistant aluminum alloy, composed of the following components in mass percentage: Cu: 6.8%, Ag: 1.2%, Mg: 0.8%, Cr: 0.3%, Mo: 0.3%, Zr: 0.12%, Sc: 0.12%, the rest is Al and unavoidable impurity elements; among them, the mass ratio of copper to magnesium is controlled to be 8.5.

[0025] The preparation method of the above-mentioned ultra-high-strength heat-resistant aluminum alloy comprises the following steps:

[0026] (1) The ingredients are prepared according to the mass percentage of each component in the alloy, among which Cu, Ag, Mg are added in the form of pure metal, and other components are added in the form of aluminum-based master alloy; the raw materials are smelted in a vacuum intermediate frequency induction melting furnace. The process is first vacuumed, then filled with 3000Pa argon for protection, stirred and left to stand after complete melting, and cast into metal molds to obtain ingots; in steps (1) of Examples 1 to 4, al...

Embodiment 2

[0034] An ultra-high-strength heat-resistant aluminum alloy consisting of the following components in mass percentage: Cu: 6.3%, Ag: 1.0%, Mg: 0.9%, Cr: 0.1%, Mo: 0.3%, Zr: 0.16%, Sc: 0.09%, Y: 0.09%, and the rest are Al and unavoidable impurity elements; among them, the mass ratio of copper to magnesium is controlled at 9.

[0035] The preparation method of the above-mentioned ultra-high-strength heat-resistant aluminum alloy comprises the following steps:

[0036] (1) Dosing according to the mass percentage of each component in the alloy, put it in a vacuum medium frequency induction melting furnace for melting, vacuumize first, then fill with 3000Pa argon for protection, stir and stand still after melting completely, and cast into a metal mold to obtain an ingot;

[0037] (2) The ingot obtained in step (1) is subjected to two-stage homogenization treatment: 420°C / 12h+515°C / 18h, and the cooling method is to cool to room temperature with the furnace;

[0038](3) Hot-rolling...

Embodiment 3

[0043] An ultra-high-strength heat-resistant aluminum alloy, composed of the following components in mass percentage: Cu: 7.2%, Ag: 1.5%, Mg: 0.8%, Cr: 0.1%, Mo: 0.5%, Zr: 0.25%, Sc: 0.09%, Er: 0.09%, Y: 0.09%, and the rest are Al and unavoidable impurity elements; among them, the mass ratio of copper to magnesium is controlled at 9.

[0044] The preparation method of the above-mentioned ultra-high-strength heat-resistant aluminum alloy comprises the following steps:

[0045] (1) Dosing according to the mass percentage of each component in the alloy, put it in a vacuum medium frequency induction melting furnace for melting, vacuumize first, then fill with 3000Pa argon for protection, stir and stand still after melting completely, and cast into a metal mold to obtain an ingot;

[0046] (2) The ingot obtained in step (1) is subjected to two-stage homogenization treatment: 420°C / 10h+515°C / 16h, and the cooling method is to cool to room temperature with the furnace;

[0047] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com