A kind of dual curing reactive polyurethane hot melt adhesive and its preparation method and application

A polyurethane hot-melt adhesive, dual-curing technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of inability to meet the rapid assembly of electronic products, inability to meet use requirements, and long positioning time. , to achieve the effect of improved positioning and curing speed, fast positioning and setting time, and improved aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

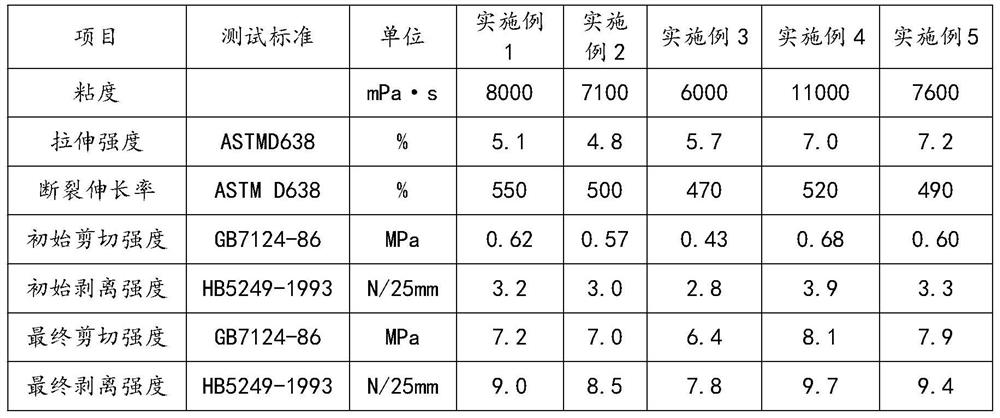

Embodiment 1

[0021] Under inert gas protection, polybutylene itaconate diol (molecular weight 2300g / mol, acid value 3.4mgKOH / g) 1000g, polybutylene adipate diol (molecular weight 2000g / mol, acid value) Add 300g of 0.14mgKOH / g) into the reactor, dehydrate at 100°C and -0.09MPa for 2h, then cool down to 70°C, add 0.5g of stannous octoate, 264g of diphenylmethane diisocyanate, at a speed of 350r / min Under mechanical stirring, react at 75°C for 2.5h, then add 10g of 2-hydroxy-2-methyl-1-phenylacetone, 15g of E-44 epoxy resin, raise the temperature to 100°C, depressurize to -0.09MPa, remove Bubble treatment for 0.5h, discharging, vacuum-sealed packaging, and a dual-curing reactive polyurethane hot-melt adhesive was obtained. The melt viscosity of the prepared polyurethane hot-melt adhesive was 8000mPa·s at 100°C. Evaluate its performance, as shown in Table 1.

Embodiment 2

[0023] Under the protection of an inert gas, polyethylene glycol itaconate diol (molecular weight 2800g / mol, acid value 3.6mgKOH / g) 1200g, polytetrahydrofuran ether diol (molecular weight 1800g / mol, acid value 0.05mgKOH / g) Add 600g into the reactor, dehydrate at 105°C and -0.095MPa for 2h, then cool down to 75°C, add 1.0g of dimorpholine diethyl ether, 381g of diphenylmethane diisocyanate, and turn at 450r / min Stir mechanically, react at 80°C for 3 hours, then add 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1-propanone 15g, E-12 epoxy Resin 18g, heated up to 100°C, decompressed to -0.095MPa, defoamed for 0.7h, discharged, vacuum-sealed and packaged to obtain a dual-curing reactive polyurethane hot-melt adhesive, which was melted at 100°C The viscosity is 7100mPa·s. Evaluate its performance, as shown in Table 1.

Embodiment 3

[0025] Under inert gas protection, polybutylene itaconate diol (molecular weight 2500g / mol, acid value 3.0mgKOH / g) 1000g, polyoxypropylene glycol (molecular weight 2000g / mol, acid value 0.03mgKOH / g) Add 250g into the reactor, dehydrate at 110°C and -0.09MPa for 2.5h, then cool down to 80°C, add 0.6g of monobutyltin oxide, 195g of hexamethylene diisocyanate, and mechanically stir at a speed of 400r / min. React at 80°C for 3.5h, then add 25g of 2,4-dihydroxybenzophenone and 22g of bisphenol A epoxy resin, heat up to 105°C, depressurize to -0.098MPa, defoam for 0.5h, and discharge. Vacuum-sealed packaging is used to prepare a dual-curing reactive polyurethane hot-melt adhesive. The melt viscosity of the prepared polyurethane hot-melt adhesive is 6000mPa·s at 100°C. Evaluate its performance, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com