Silicon-containing high-temperature-resistant insulating coating and preparation method and application thereof

A technology for insulating coatings and high temperature resistance, applied in the direction of anti-corrosion coatings, coatings, etc., to achieve strong adhesion, excellent corrosion resistance, and good surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

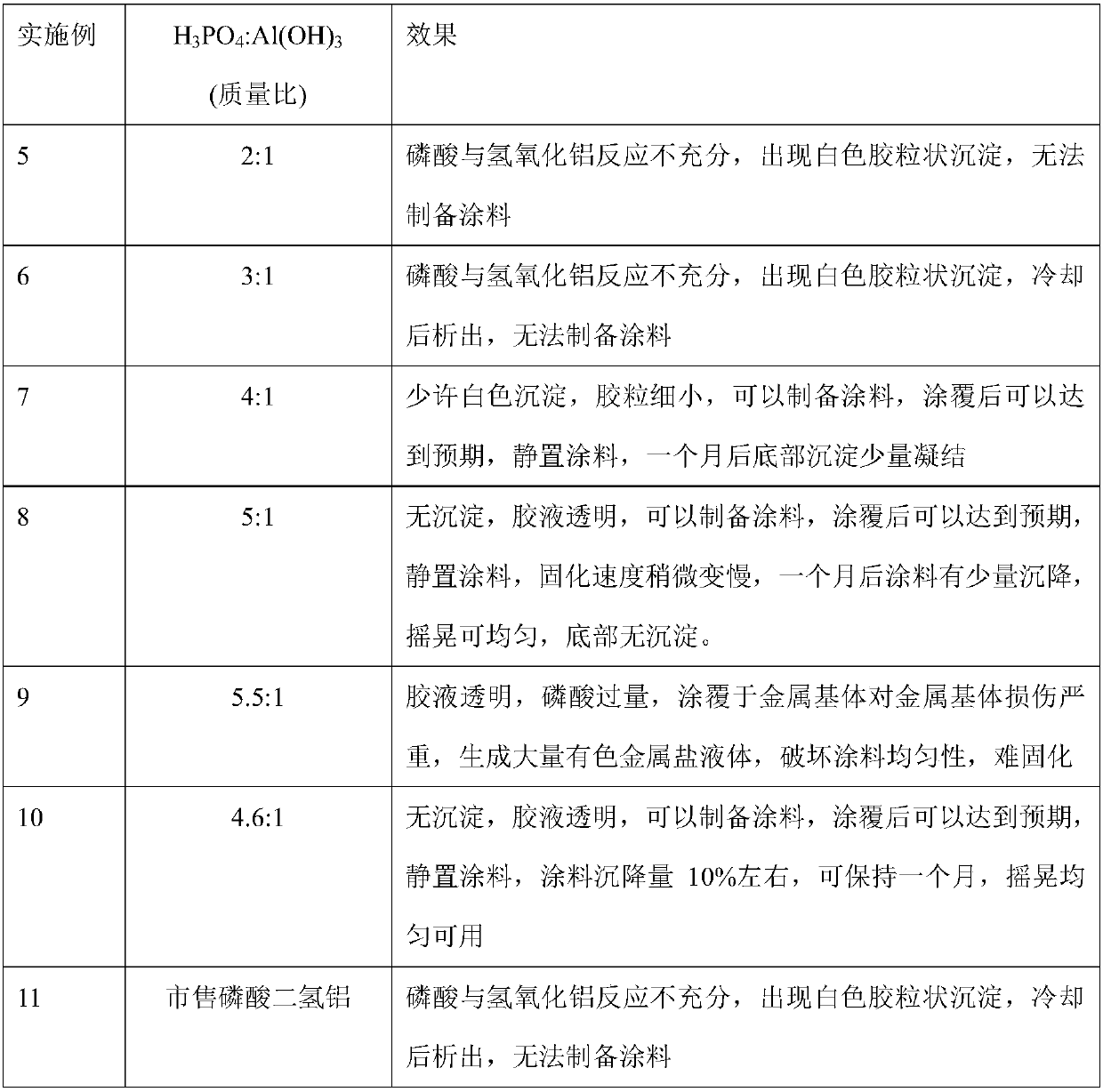

[0032] (1) Preparation of phosphate solution: phosphoric acid solution and metal hydroxide are placed in a reaction vessel and mixed and heated to a boiling state for reaction until the reaction system becomes transparent and the transparency no longer increases; then, the reaction system is cooled to room temperature, and aging at room temperature for more than 12 hours, preferably aging for 12 hours to 36 hours, to obtain a phosphate solution;

[0033] (2) Preparation of silicon-containing high-temperature insulating coating: add phosphate solution, silicon oxide, aluminum oxide, zinc oxide, silica sol, diluent and optional boric acid to the phosphate solution, and pass through the ball milling method after stirring evenly The mixture is mixed for more than 2 hours, and ball milled for 2 hours to 8 hours, so as to obtain the silicon-containing high temperature resistant insulating coating.

Embodiment 1

[0036] Embodiment 1: Preparation of aluminum phosphate salt solution

[0037] Weigh 230g of 85% concentration phosphoric acid, Al(OH) 3 50g of the powder was placed in a reaction vessel and stirred evenly. Stir the reaction and heat up to boiling state, stop heating after the reaction system is transparent. The reaction system was cooled to room temperature and aged for 12 hours.

Embodiment 2

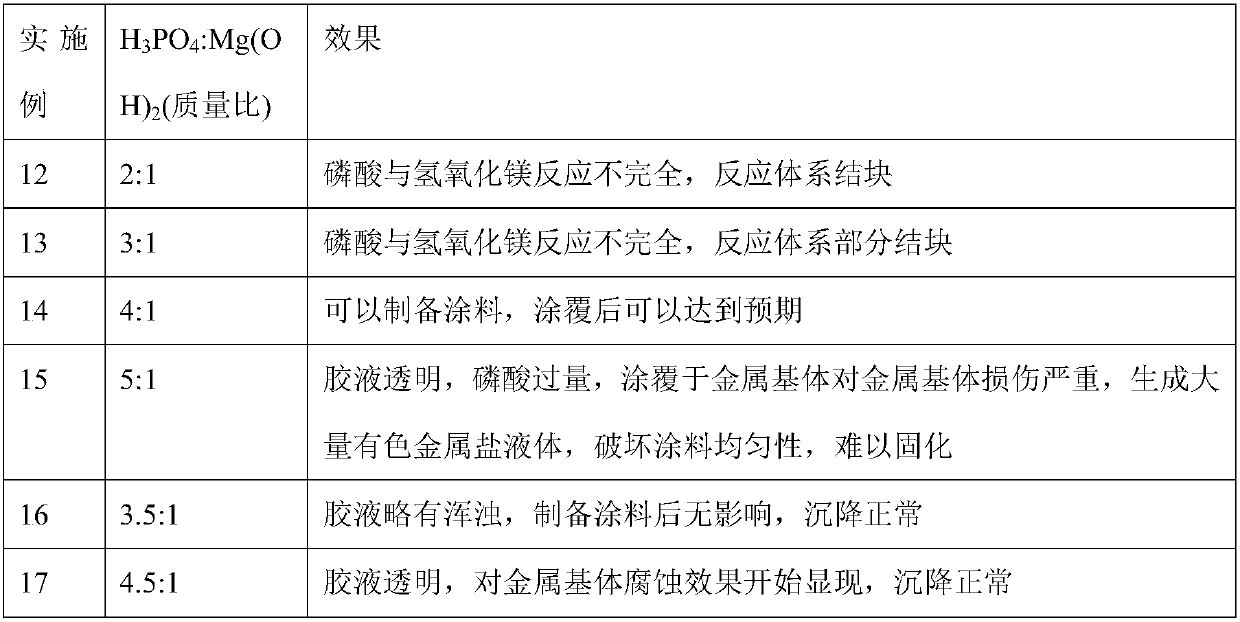

[0038] Embodiment 2: preparation magnesium phosphate salt and aluminum phosphate salt solution

[0039] Weigh 290g of 85% concentrated phosphoric acid, Al(OH) 3 Powder 50g, Mg(OH) 2 15g of powder, placed in a reaction vessel and stirred evenly. Stir the reaction and heat up to boiling state, stop heating after the reaction system is transparent. The reaction system was cooled to room temperature and aged for 16 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com