A kind of alkali-free liquid accelerator and preparation method thereof

A technology of quick-setting agent and liquid, which is applied in the field of alkali-free liquid quick-setting agent and its preparation, which can solve the problems of increasing the probability of alkali-aggregate reaction, restricting promotion, and causing disability, so as to improve environmental adaptability and raw material safety The effect of easy availability and small geographical restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

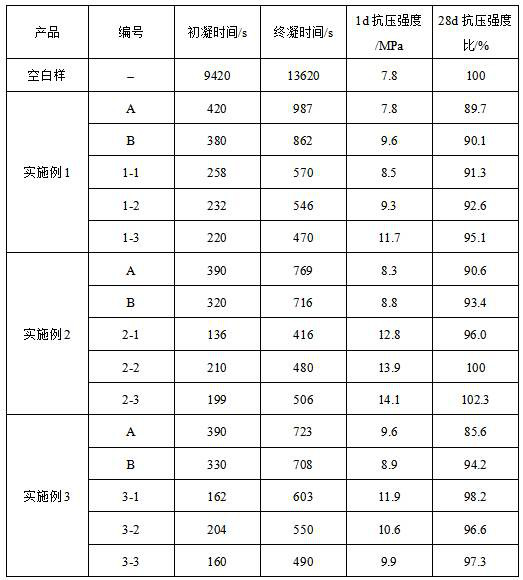

Embodiment 1

[0046] Add 50kg of water, 2kg of triethanolamine, 1kg of sodium fluoride, and 2kg of zirconium sulfate into the reactor, stir until the solution is clear, then add 45kg of aluminum sulfate octadecahydrate, raise the temperature to 90°C, and continue stirring until the solution is clear. After cooling down to room temperature, solution A was obtained;

[0047] Add 36.5kg of water, 3kg of triethanolamine, and 45kg of aluminum sulfate octadecahydrate into the reactor, and slowly add 12.5kg of sodium metaaluminate solution (40%) into the reactor under stirring, continue to stir for 20 minutes, and then raise the temperature to Keep at 50°C for 1 h until the solution is clear, then cool down to room temperature, add 3 kg of 20% silica sol solution, and stir for 30 min to obtain solution B;

[0048] Mix solutions A and B according to the mass ratio of 2:3, 1:1, 3:2 to obtain alkali-free liquid accelerators 1-1, 1-2, 1-3.

Embodiment 2

[0050] Add 45kg of water, 2kg of ethanolamine, 1kg of sodium fluoride, and 2kg of titanium sulfate into the reactor, stir until the solution is clear, then add 50kg of aluminum sulfate octadecahydrate, raise the temperature to 85°C, continue stirring until the solution is clear, and the temperature of the reactor drops Solution A is obtained after reaching room temperature;

[0051] Add 32kg of water, 3kg of triethanolamine, and 50kg of aluminum sulfate octadecahydrate into the reactor, slowly add 10kg of sodium metaaluminate solution (40%) into the reactor under stirring, continue stirring for 20 minutes, and then raise the temperature to 70°C Keep for 1 h until the solution is clear, then cool down to room temperature, add 5 kg of 20% silica sol solution, and stir for 30 min to obtain solution B;

[0052] Mix solutions A and B according to the mass ratio of 2:3, 1:1, 3:2 to obtain alkali-free liquid accelerators 2-1, 2-2, and 2-3.

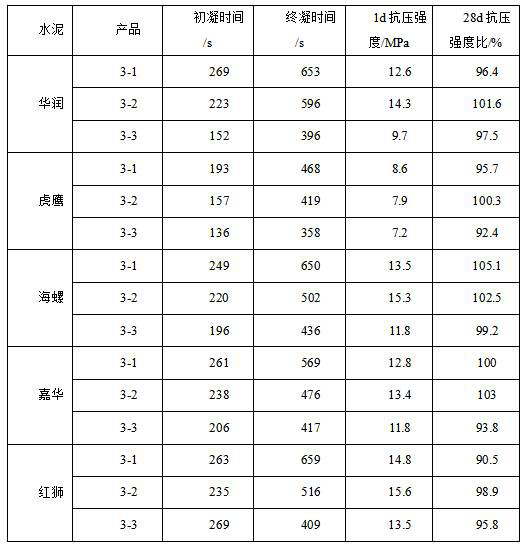

Embodiment 3

[0054] Add 36kg of water, 4kg of ethanolamine, 1kg of sodium fluoride, and 2kg of cerium sulfate into the reactor, stir until the solution is clarified, then add 57kg of aluminum sulfate octadecahydrate, raise the temperature to 80°C, continue stirring until the solution is clarified, and the temperature of the reactor drops Solution A is obtained after reaching room temperature;

[0055] Add 28kg of water, 3kg of triisopropanolamine, and 55kg of aluminum sulfate octadecahydrate into the reactor, and slowly add 8kg of sodium metaaluminate solution (40%) into the reactor under stirring, continue stirring for 20 minutes, and then raise the temperature Keep at 70°C for 1 h until the solution is clear, then cool down to room temperature, add 6 kg of 20% silica sol solution, and stir for 30 min to obtain solution B;

[0056] Mix solutions A and B according to the mass ratio of 2:3, 1:1, and 3:2 to obtain alkali-free liquid accelerators 3-1, 3-2, and 3-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com