Preparation method of proscar tablet, and prepared proscar tablet

A technology of finasteride and androsteride tablets, which is applied in the directions of non-active ingredient medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 5mg finasteride tablets

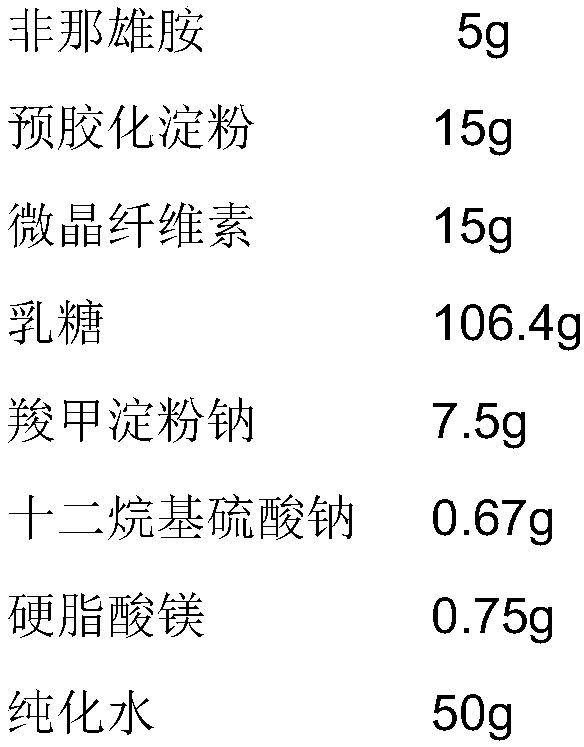

[0043] (1) Plain tablets

[0044]

[0045] (2) Coating

[0046] Stomach Dissolved Opadry: 8%

[0047] Purified water: 92%

[0048] Preparation process: After mixing the finasteride raw material and lactose, pregelatinized starch, microcrystalline cellulose, sodium starch glycolate, stir for 4 minutes to make the mixture uniform, add sodium lauryl sulfate aqueous solution for stirring, shearing and granulation 1min, 24 mesh sieve wet granules, after drying at 60-65°C until the moisture content is less than 4.0%, 24 mesh sieve, mixed with magnesium stearate, and compressed according to the theoretical tablet weight. If the uniformity and friability of the plain tablets are tested, they can be coated.

Embodiment 2

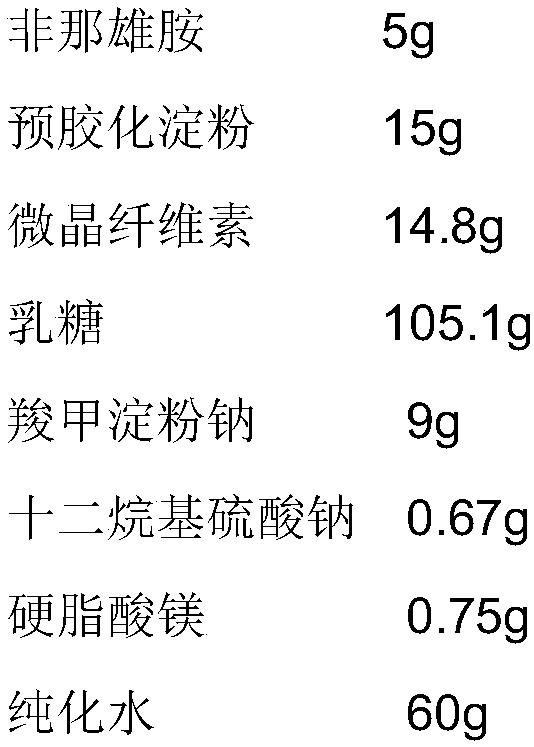

[0050] 5mg finasteride tablets

[0051] (1) Plain tablets

[0052]

[0053] (2) Coating

[0054] Stomach dissolving Opadry: 10%

[0055] Purified water: 90%

[0056] Preparation process: After mixing the raw material of finasteride with lactose, pregelatinized starch, microcrystalline cellulose and sodium starch glycolate, stir for 5 minutes to make the mixture uniform, add sodium lauryl sulfate aqueous solution for stirring, shearing and granulation 1min, 24 mesh sieve wet granules, dried at 60-65°C until the moisture content is less than 4.0%, 24 mesh sieve, mixed with lubricant, and compressed according to theoretical tablet weight. If the uniformity and friability of the plain tablets are tested, they can be coated.

Embodiment 3

[0058] 5mg finasteride tablets

[0059] (1) Plain tablets

[0060]

[0061]

[0062] (2) Coating

[0063] Stomach Dissolved Opadry: 8%

[0064] Purified water: 92%

[0065] Preparation process: After mixing finasteride raw material with lactose, pregelatinized starch, microcrystalline cellulose, sodium starch glycolate, stir for 5 minutes to make the mixture uniform, add sodium lauryl sulfate aqueous solution for stirring, shearing and granulation 1min, 24 mesh sieve wet granules, dried at 60-65°C until the moisture content is less than 4.0%, 24 mesh sieve, mixed with lubricant, and compressed according to theoretical tablet weight. If the uniformity and friability of the plain tablets are tested, they can be coated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com