Heat treatment type conductive film forming method on passivation light metal

A conductive, light metal technology, applied in the field of forming conductive films, which can solve the problems of complicated processing, rough processing surface, poor productivity, etc.

Active Publication Date: 2021-05-25

ISHIHARA CHEM

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, especially in the above-mentioned secondary zinc dipping method utilizing the substitution reaction of zinc and aluminum, there is a problem that since the particles of the zinc film formed initially are large, it is necessary to peel them off and then form a film from the zinc particles again, which is not only cumbersome to process. The productivity is not good, and the treated surface is relatively rough, making it difficult to form a smooth film in subsequent electroplating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

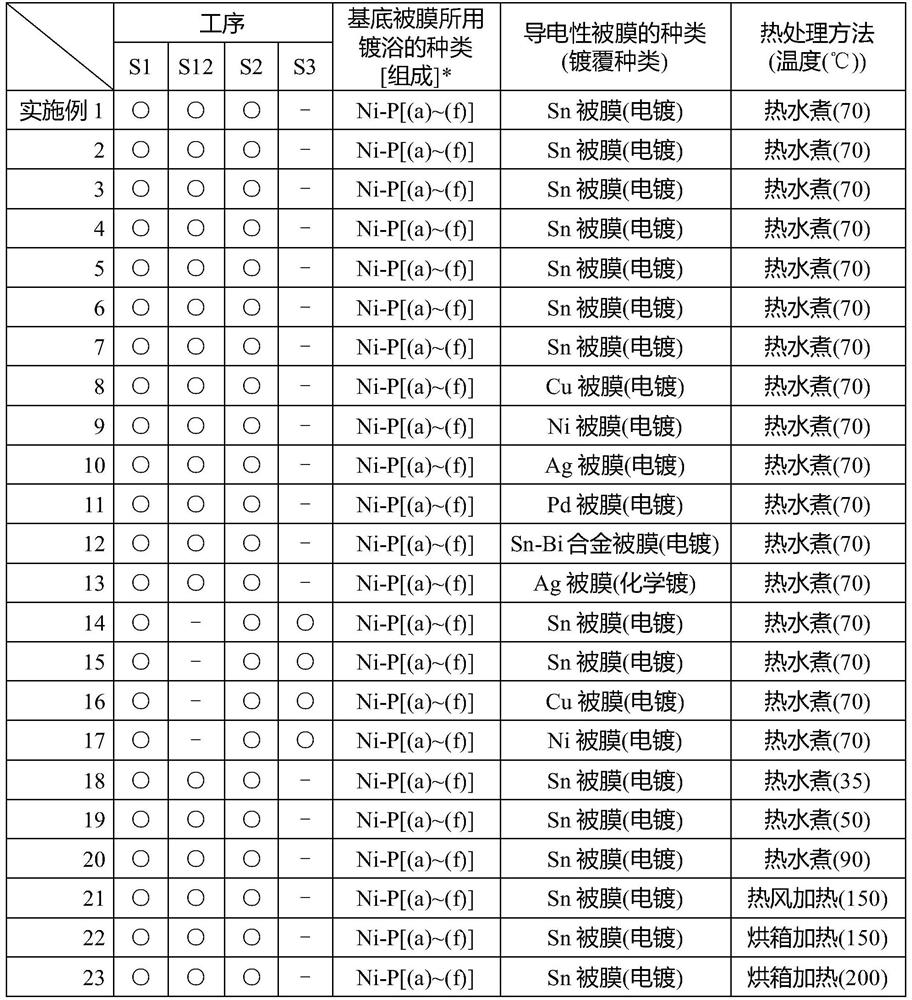

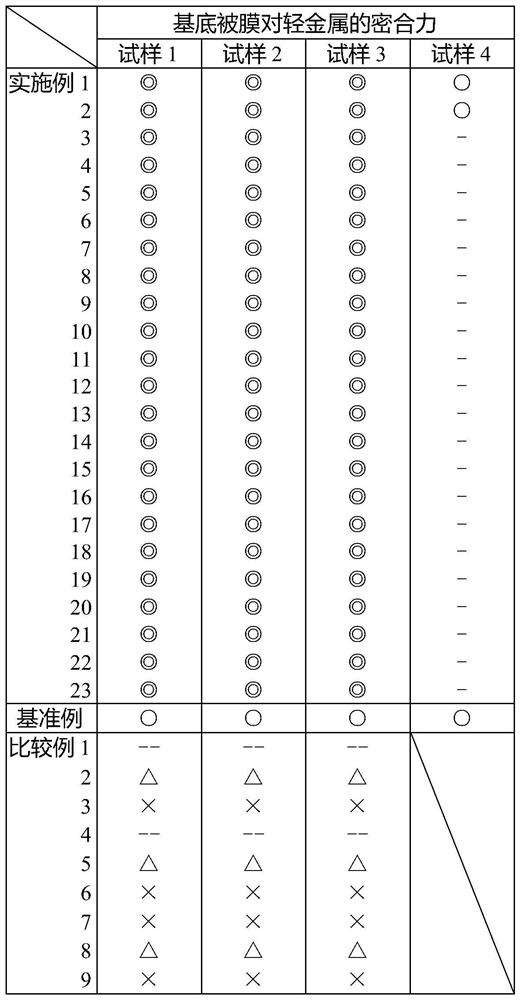

Embodiment 1~7

[0141] Examples 1 to 7: Nickel-phosphorus coating (base coating) / tin coating (conductive coating)

Embodiment 8

[0142] Example 8: Nickel-Phosphorus coating (base coating) / copper coating (conductive coating)

Embodiment 9

[0143] Example 9: Nickel-Phosphorus coating (base coating) / nickel coating (conductive coating)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a method for forming a heat-treated conductive film on a passivation-forming light metal, which is to form a conductive film such as silver, copper, tin, etc. on a passivation-forming light metal selected from aluminum, magnesium, and titanium through a base film. A coating method, the base coating is a nickel-phosphorus coating, the base coating is formed by using a nickel-phosphorus electroplating bath containing a prescribed soluble nickel salt, a phosphorus-containing compound, a complexing agent, a surfactant, a buffer, and a brightener, And heat-treating the base coating, or the base coating and the conductive coating under conditions including a low temperature range of 30°C or higher, can strengthen the adhesion of the base coating to the passivation light metal compared to a method without heat treatment. A conductive film is formed on the passivation-forming light metal more firmly.

Description

technical field [0001] The present invention relates to a method for forming a conductive film on specific light metals such as aluminum and magnesium that are prone to form passive states. According to the present invention, there is provided a method of forming a conductive film of copper, silver, tin, etc. with strong adhesion on the above-mentioned light metal that is difficult to form a plated film by applying heat treatment. Background technique [0002] Specific light metals such as aluminum, magnesium, and titanium tend to form a strong oxide film in the atmosphere and become passive. Therefore, even if it is desired to form a conductive film such as copper, silver, and tin on the surface of these light metals, it is difficult to pass it through plating. for surface treatment. In addition, even if a plated film can be formed, it is difficult to ensure good adhesion with the above-mentioned light metal. [0003] Therefore, conventionally, the above-mentioned light m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25D5/30

CPCC23C18/18C23C18/31C23C28/02C25D3/12C25D5/50C25D5/12C23C18/1692C23C18/1831C25D3/562C25D5/38C25D5/42C25D5/44C25D5/505

Inventor 藤原雅宏山本和志

Owner ISHIHARA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com