Glasses lens

A technology for spectacle lenses and spectacles, applied in the directions of glasses/protective glasses, glasses/goggles, instruments, etc., can solve the problems of thick resin lenses, easy to scratch, easy to break lenses, etc., and achieve the effect of low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

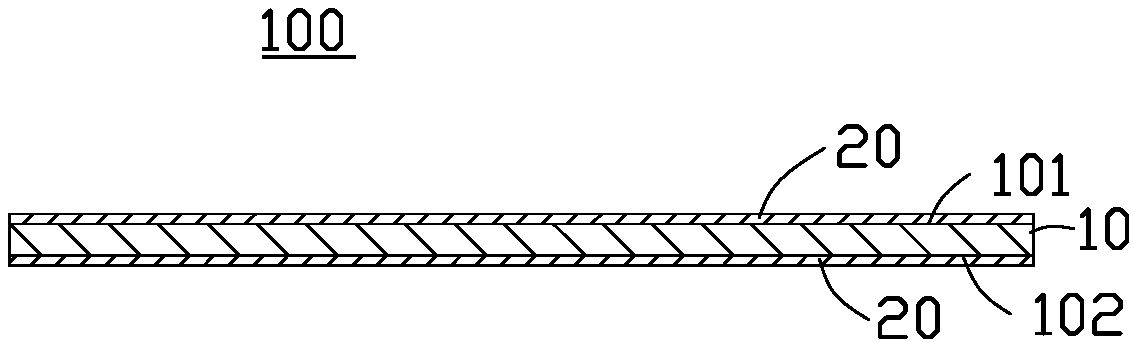

[0024] see figure 1 , is a spectacle lens 100 provided in the first embodiment of the present invention. The spectacle lens 100 includes a spectacle body 10 and a functional film layer 20 formed on at least one surface of the spectacle body 10 .

[0025] The glasses body 10 includes a front surface 101 and a rear surface 102. In this embodiment, the functional film layer 20 is simultaneously formed on the front surface 101 and the rear surface 102 of the glasses body 10. In other embodiments, only The functional film layer 20 is formed on one surface of the glasses body 10 . The main component of the lens body 10 is a cyclic block copolymer (Cyclic Block Copolymer, CBC for short). The glasses body 10 is formed by injection molding.

[0026] Due to the low specific gravity of the cyclic block copolymer, the lens body 10 formed by using the cyclic block copolymer through the injection molding process has ultra-high transparency, can meet the demand for lightness and thinning,...

no. 2 example

[0034] The functional film layer is an antistatic layer. The antistatic layer is treated on the surface of the lens body 10 by spraying, dipping and other methods to form an antistatic agent molecular layer on the surface of the lens body 10 . The lipophilic group of its molecule is planted inside the lens, and the hydrophilic group is aligned on the air side. The lipophilic group keeps the antistatic agent and the lens compatible to a certain extent. The latter absorbs water molecules in the air to form a uniformly distributed conductive solution on the surface of the material, or ionizes and conducts surface charges by itself to achieve antistatic effect. Wherein, the antistatic agent molecule can be cationic, amphoteric, anionic or nonionic.

no. 3 example

[0036] The functional film layer is a hard coating. The hard coat protection layer is used to protect the spectacle lens 100, increase the strength of the spectacle body 10, and prevent the spectacle lens 100 from being scratched or broken.

[0037] The hard coat protective layer is formed by mixing dopamine, inorganic oxide particles and a solvent and coating on the surface of the spectacle lens.

[0038] The mass fraction of the dopamine in the hard coat protective layer is 1%-40%, the mass fraction of the inorganic oxide particles is 40-80%, and the mass fraction of the solvent is 5%-50%.

[0039] The inorganic oxide particles include but not limited to one or more of silica particles, zirconia particles, alumina particles and titania particles. The particle size range of the inorganic oxide particles is 1-1000 nm.

[0040] The solvent is water, alcoholic aqueous solution or oxidizing aqueous solution. Described alcoholic aqueous solution is methanol aqueous solution, et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com