Semiconductor package member and fabrication method thereof

A semiconductor and packaging technology, applied in the field of semiconductor packaging and its manufacturing method, can solve problems such as noise generation, affecting the overall height of cooling fans, and inability to meet the thinning requirements of electronic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

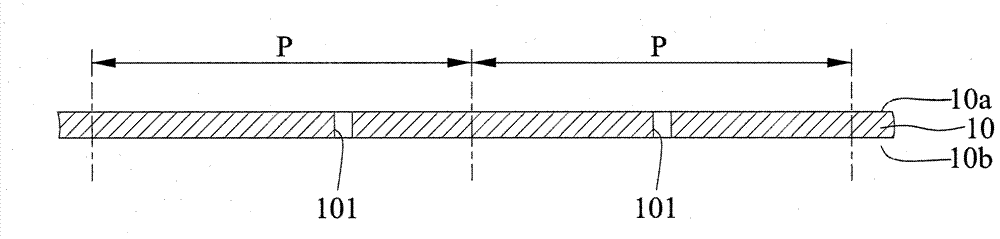

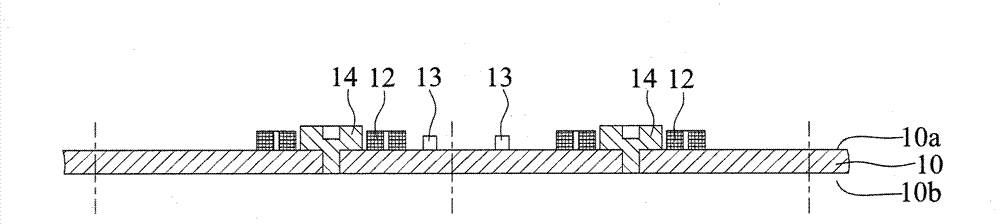

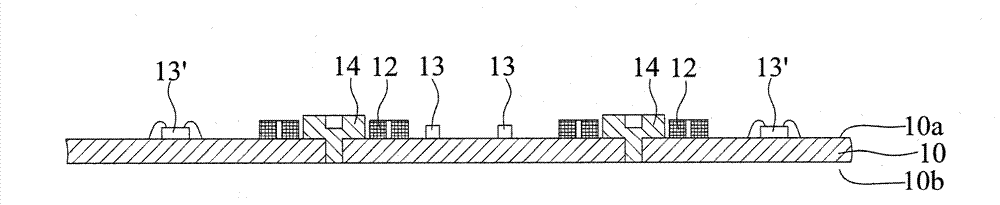

[0052] see Figure 1A to Figure 1E ', which is a cross-sectional view of the manufacturing method of the semiconductor package of the present invention.

[0053] Such as Figure 1A As shown, first, a substrate 10 having a first surface 10 a and a second surface 10 b is prepared, and a plurality of packaging units P are planned on the substrate 10 . In this embodiment, the substrate 10 has a first positioning hole 101 penetrating through the first surface 10a and the second surface 10b, wherein the first positioning hole 101 can be formed in the center of the packaging unit P of the substrate, or The first positioning hole 101 can be formed eccentrically in the packaging unit P of the substrate 10 , and more space can be left on the first surface 10 a for disposing electronic components, especially functional chips.

[0054] Such as Figure 1B As shown, the shaft sleeve 14 is inserted in the first positioning hole 101; and the stator group 12 and at least one electronic comp...

no. 2 Embodiment

[0060] see Figure 2A to Figure 2C , which is a cross-sectional view of the manufacturing method of the semiconductor package according to the second embodiment of the present invention. In this embodiment, the manufacturing method is substantially the same as that of the first embodiment, the difference is that the substrate 10' is not preset with positioning holes, but is fabricated after forming the encapsulant. The other steps of forming the semiconductor package are the same as those in the first embodiment, so they will not be repeated here.

[0061] Such as Figure 2A As shown, a stator group 12 and at least one electronic component 13 are provided on the first surface 10a' and electrically connected to the first surface 10a', and the substrate 10' formed with the encapsulant 15 is provided.

[0062] Such as Figure 2B As shown, the second positioning hole 201 passing through the substrate 10' and the encapsulant 15 is formed by drilling technology such as laser. an...

no. 3 Embodiment

[0064] This embodiment also provides a method for making a semiconductor package that increases heat dissipation performance, such as Figure 3A The top view shown, can be continued Figure 1C or Figure 2A After forming the encapsulant 15, the ventilation holes 300 penetrating the encapsulant 15 and the substrates 10, 10' are formed by, for example, laser cutting.

[0065] Such as Figure 3B As shown, when the semiconductor package is in operation, the airflow S can enter from the bottom to increase the heat dissipation performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com