Die casting aluminum alloy with high strength and toughness as well as preparation method thereof

A technology of casting aluminum alloy and tough pressing, which is applied in the field of high-strength and tough die-casting aluminum alloy and its preparation, can solve the problems of low pass rate, high cost consumption, and lengthened process flow, etc., and achieve good die-casting performance and meet performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

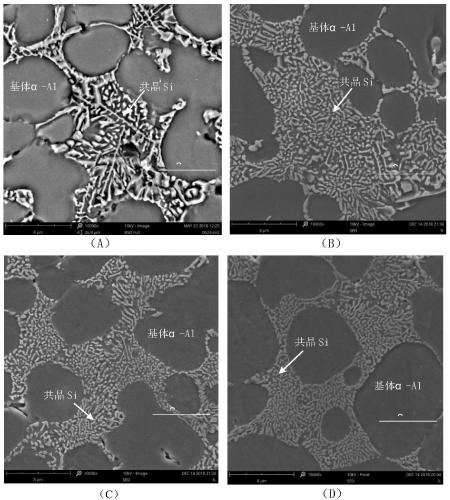

Image

Examples

Embodiment 1

[0026] The weight percent of each component of a high-strength and toughness die-casting aluminum alloy in this embodiment is: Si: 10.0wt%; Mg: 0.3wt%; Mn: 0.6wt%; Sr: 0.04wt%; Zn: 1.0wt%; RE : 0.1wt%; Fe: w(Fe)≤0.16wt%; the remaining impurities are less than or equal to 0.25%, and the balance is Al.

[0027] A method for preparing a high-strength and toughness die-casting aluminum alloy in this embodiment includes the following steps:

[0028] (1) Drying: Preheat the prepared raw materials of pure aluminum ingot, industrial silicon, pure magnesium block, aluminum strontium alloy, pure zinc block, aluminum manganese alloy and aluminum rare earth alloy to 200°C for drying treatment;

[0029] (2) Melting: Use a crucible resistance furnace for smelting, first preheat the resistance furnace to 200°C, and then evenly coat the inner wall of the crucible with paint; after drying, first melt the weighed pure aluminum, and wait for the pure aluminum After melting, raise the temperatur...

Embodiment 2

[0032] The weight percent of each component of a high-strength and toughness die-casting aluminum alloy in this embodiment is: Si: 10.0wt%; Mg: 0.3wt%; Mn: 0.6wt%; Sr: 0.04wt%; Zn: 1.5wt%; RE : 0.1wt%; Fe: w(Fe)≤0.16wt%; the remaining impurities are less than or equal to 0.25%, and the balance is Al.

[0033] A method for preparing a high-strength and toughness die-casting aluminum alloy in this embodiment includes the following steps:

[0034] (1) Drying: Preheat the prepared raw materials of pure aluminum ingot, industrial silicon, pure magnesium block, aluminum-strontium alloy, pure zinc block and aluminum-manganese alloy to 200°C for drying treatment;

[0035] (2) Melting: Use a crucible resistance furnace for smelting, first preheat the resistance furnace to 200°C, and then evenly coat the inner wall of the crucible with paint; after drying, first melt the weighed pure aluminum, and wait for the pure aluminum After melting, heat up to 780°C, add industrial silicon that h...

Embodiment 3

[0038] The weight percent of each component of a high-strength and tough die-casting aluminum alloy in this embodiment is: Si: 10.0wt%; Mg: 0.3wt%; Mn: 0.6wt%; Sr: 0.04%; Zn: 2.5wt%; RE: 0.1wt%; Fe: w(Fe)≤0.16wt%; the total amount of other impurities is less than or equal to 0.25%, and the balance is Al.

[0039] A method for preparing a high-strength and toughness die-casting aluminum alloy in this embodiment includes the following steps:

[0040] (1) Drying: Preheat the prepared raw materials of pure aluminum ingots, industrial silicon, pure magnesium blocks, aluminum strontium alloys, aluminum rare earth alloys and aluminum manganese alloys to 200°C for drying treatment;

[0041] (2) Melting: Use a crucible resistance furnace for smelting, first preheat the resistance furnace to 200°C, and then evenly coat the inner wall of the crucible with paint; after drying, first melt the weighed pure aluminum, and wait for the pure aluminum After melting, raise the temperature to 780°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com