Leather isolating layer finishing agent, preparation method thereof, and leather

A technology of isolation layer and finishing agent, which is applied in the field of leather isolation layer finishing agent and its preparation, and can solve problems such as unfavorable operators and working environment, decreased bondability of pulp layer resin, affecting leather quality and appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

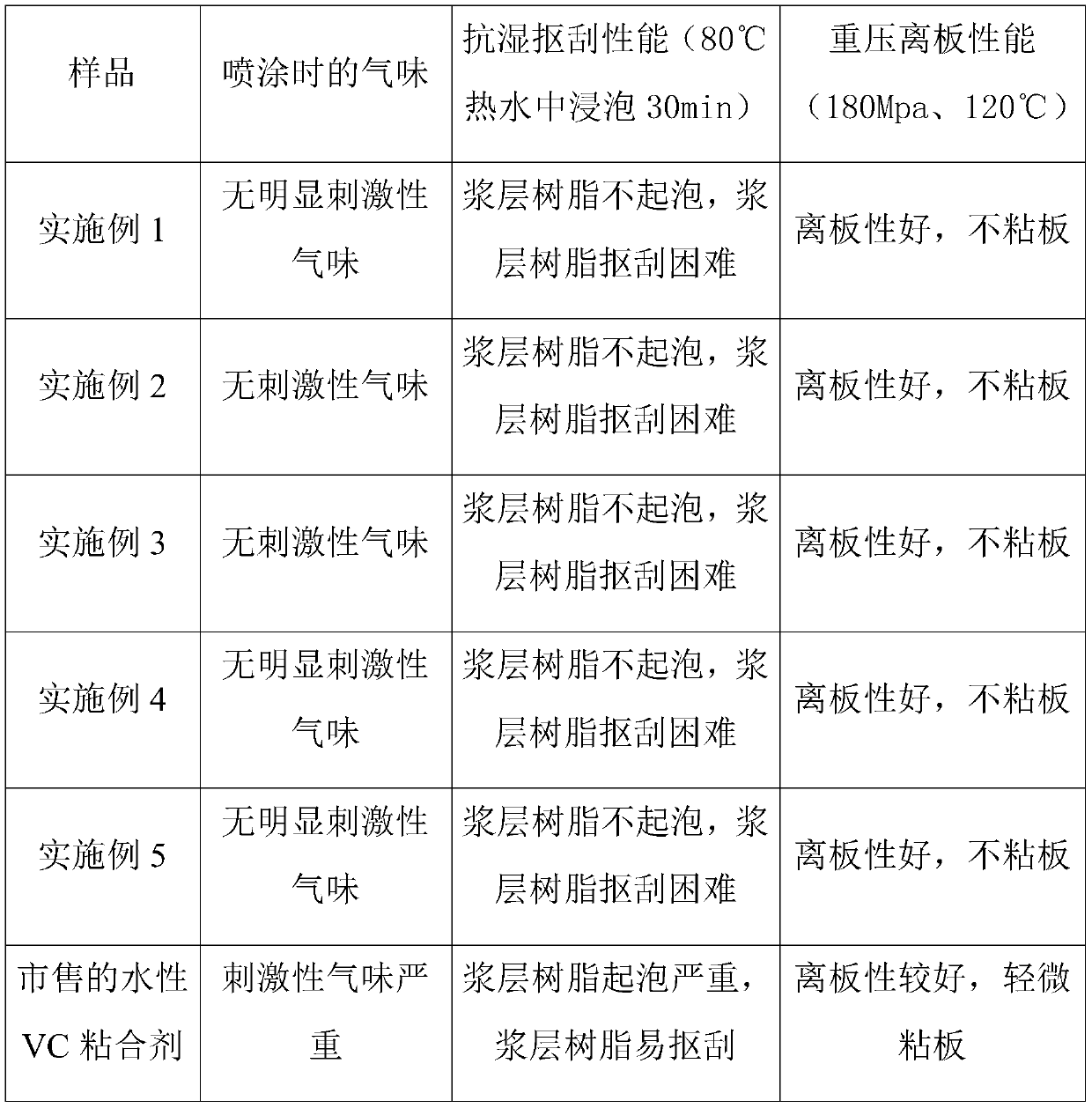

Examples

Embodiment 1

[0047] (1) Preparation of water-based polyurethane: 10 parts of isophorone diisocyanate, 10 parts of polycaprolactone diol (molecular weight is 2000) and 1 part of 2,2-dimethylolpropionic acid are added to the reactor, Stir and mix evenly, heat up to 70°C and react for 4 hours, then cool down to 40°C, continue to add 1 part of triethanolamine for neutralization, then add 150 parts of water, after uniform dispersion, then add 1 part of hydrazine hydrate, stir for 1 hour, and get Water-based polyurethane containing amino groups in the end groups.

[0048] (2) Preparation of water-based epoxy resin: Add 10 parts of Tween 80 to 700 parts of water and stir evenly to obtain a mixed solution, which is added to 100 parts of epoxy resin E-44, and dispersed at a high speed to obtain a water-based epoxy resin resin.

[0049] (3) Preparation of finishing agent for leather isolation layer: take 40 parts of water-based polyurethane prepared in step (1), add 30 parts of water-based epoxy re...

Embodiment 2

[0051] (3) Preparation of water-based polyurethane: 15 parts of dicyclohexylmethane diisocyanate, 12 parts of polycaprolactone diol (molecular weight is 2000) and 1.5 parts of 2,2-dimethylolbutyric acid are added to the reactor, Stir and mix evenly, heat up to 80°C and react for 3 hours, then cool down to 45°C, continue to add 1.5 parts of triethylamine for neutralization, then add 160 parts of water, after uniform dispersion, then add 1.2 parts of diethylenetriamine, and stir for reaction After 1.5 h, the water-based polyurethane containing amino groups in the end groups was obtained.

[0052] (4) Preparation of water-based epoxy resin: Add 15 parts of Tween 80 to 750 parts of water and stir evenly to obtain a mixed solution, which is added to 150 parts of epoxy resin E-44, and dispersed at a high speed to obtain a water-based epoxy resin resin.

[0053] (3) Preparation of finishing agent for leather isolation layer: take 50 parts of water-based polyurethane prepared in step...

Embodiment 3

[0055] (5) Preparation of water-based polyurethane: 20 parts of isophorone diisocyanate, 15 parts of polycaprolactone diol (molecular weight is 2000) and 2 parts of 2,2-dimethylolpropionic acid are added to the reactor, Stir and mix evenly, heat up to 80°C and react for 2.5 hours, then cool down to 45°C, continue to add 2 parts of triethanolamine for neutralization, then add 170 parts of water, after uniform dispersion, then add 1.8 parts of hydrazine hydrate, and stir for 1.5 hours , to obtain water-based polyurethane containing amino groups in the end group.

[0056] (6) Preparation of water-based epoxy resin: Add 20 parts of Tween 80 to 800 parts of water and stir evenly to obtain a mixed solution, which is added to 200 parts of epoxy resin E-44, and dispersed at a high speed to obtain a water-based epoxy resin resin.

[0057] (3) Preparation of finishing agent for leather isolation layer: Take 60 parts of water-based polyurethane prepared in step (1), add 50 parts of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com