Self cleaning heat insulation paint for building outer wall and roof and preparation method thereof

A heat-insulating coating and self-cleaning technology, applied in the direction of coating, etc., can solve the problems that affect the aesthetics of buildings and city appearance, adverse effects, coatings are easily contaminated with dust, oil, etc., and achieve good self-cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

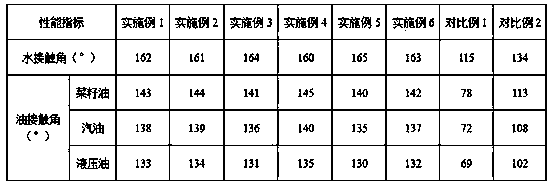

Examples

Embodiment 1

[0023] (1) Stir and heat the ethylene-vinyl acetate copolymer emulsion to 67°C, add ammonium persulfate aqueous solution, sodium bicarbonate aqueous solution, and sodium dodecylsulfonate under nitrogen protection, heat up to 83°C, and then add dropwise Perfluoroalkyl ethyl acrylate and acrylic acid were copolymerized for 4 hours under stirring to obtain a composite emulsion; the solid content of the ethylene-vinyl acetate copolymer emulsion was 56%, and the mass ratio of ethylene to vinyl acetate was 15:85 The mass concentration of ammonium persulfate aqueous solution is 7%; The mass concentration of sodium bicarbonate aqueous solution is 4%; Perfluoroalkyl ethyl acrylate is perfluorooctyl ethyl acrylate; The parts by weight of each raw material are, ethylene- Vinyl acetate copolymer emulsion 61.4 parts by weight, ammonium persulfate aqueous solution 2.5 parts by weight, sodium bicarbonate aqueous solution 1.4 parts by weight, sodium dodecylsulfonate 0.7 parts by weight, perflu...

Embodiment 2

[0028] (1) Stir and heat the ethylene-vinyl acetate copolymer emulsion to 66°C, add ammonium persulfate aqueous solution, sodium bicarbonate aqueous solution, and sodium dodecylsulfonate under nitrogen protection, raise the temperature to 81°C, and then add dropwise Perfluoroalkyl ethyl acrylate and acrylic acid, copolymerization reaction 4.5h under stirring state, make composite emulsion; The solid content of ethylene-vinyl acetate copolymer emulsion is 52%, and the mass ratio of ethylene and vinyl acetate is 15: 85; the mass concentration of ammonium persulfate aqueous solution is 6%; the mass concentration of sodium bicarbonate aqueous solution is 3.5%; perfluoroalkyl ethyl acrylate is perfluorohexyl ethyl acrylate; the parts by weight of each raw material are, ethylene- Vinyl acetate copolymer emulsion 63.9 parts by weight, ammonium persulfate aqueous solution 2.3 parts by weight, sodium bicarbonate aqueous solution 1.2 parts by weight, sodium dodecylsulfonate 0.6 parts by ...

Embodiment 3

[0033] (1) Stir and heat the ethylene-vinyl acetate copolymer emulsion to 69°C, add ammonium persulfate aqueous solution, sodium bicarbonate aqueous solution, and sodium dodecylsulfonate under nitrogen protection, raise the temperature to 84°C, and then add dropwise Perfluoroalkyl ethyl acrylate and acrylic acid, copolymerization reaction 3.5h under stirring state, make composite emulsion; The solid content of ethylene-vinyl acetate copolymer emulsion is 58%, and the mass ratio of ethylene and vinyl acetate is 15: 85; the mass concentration of ammonium persulfate aqueous solution is 7%; the mass concentration of sodium bicarbonate aqueous solution is 4.5%; perfluoroalkyl ethyl acrylate is perfluorobutyl ethyl acrylate; the parts by weight of each raw material are, ethylene - 58.7 parts by weight of vinyl acetate copolymer emulsion, 2.7 parts by weight of ammonium persulfate aqueous solution, 1.7 parts by weight of sodium bicarbonate aqueous solution, 0.9 parts by weight of sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com