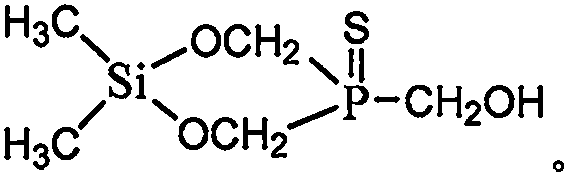

Reactive flame retardant thiophosphoryl heterocyclic silicate compound and preparation method thereof

A flame retardant thiophosphonyl and reactive technology, which is applied in the field of reactive flame retardant thiophosphono heterocyclic silicate compounds and their preparation, can solve problems such as affecting the performance of materials, and achieve less investment in equipment , High flame retardant efficiency, improve the effect of flame retardant carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

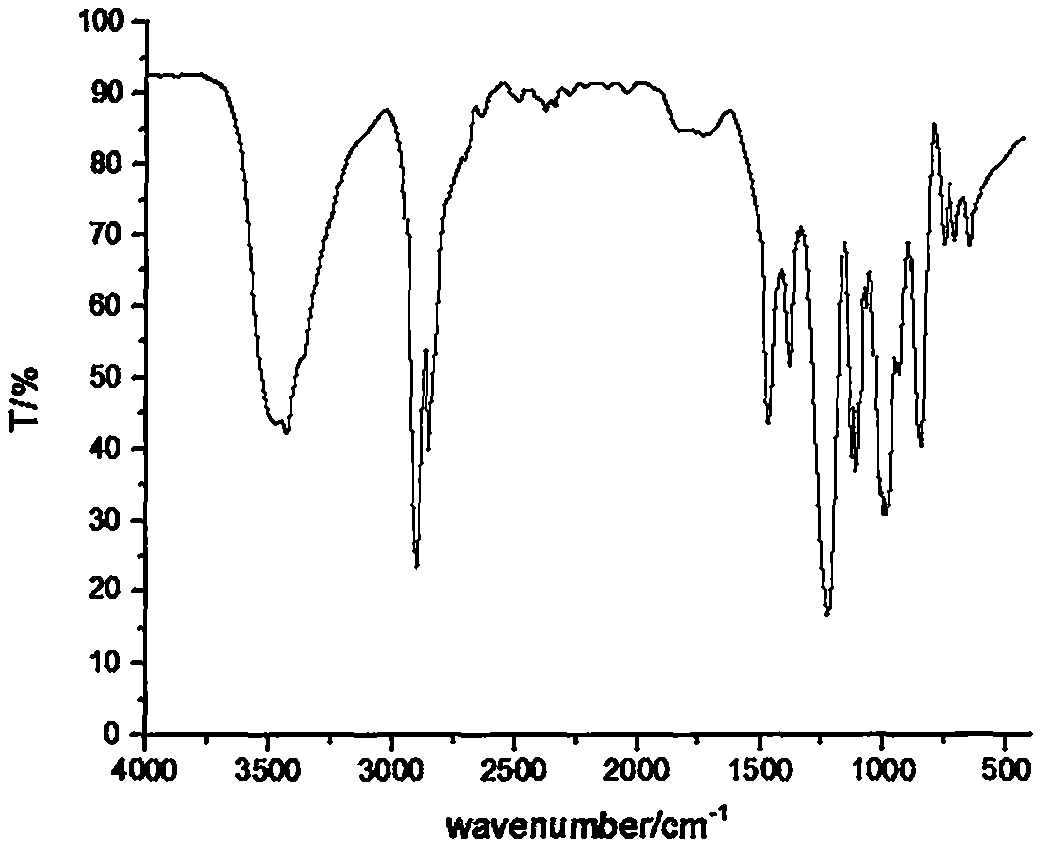

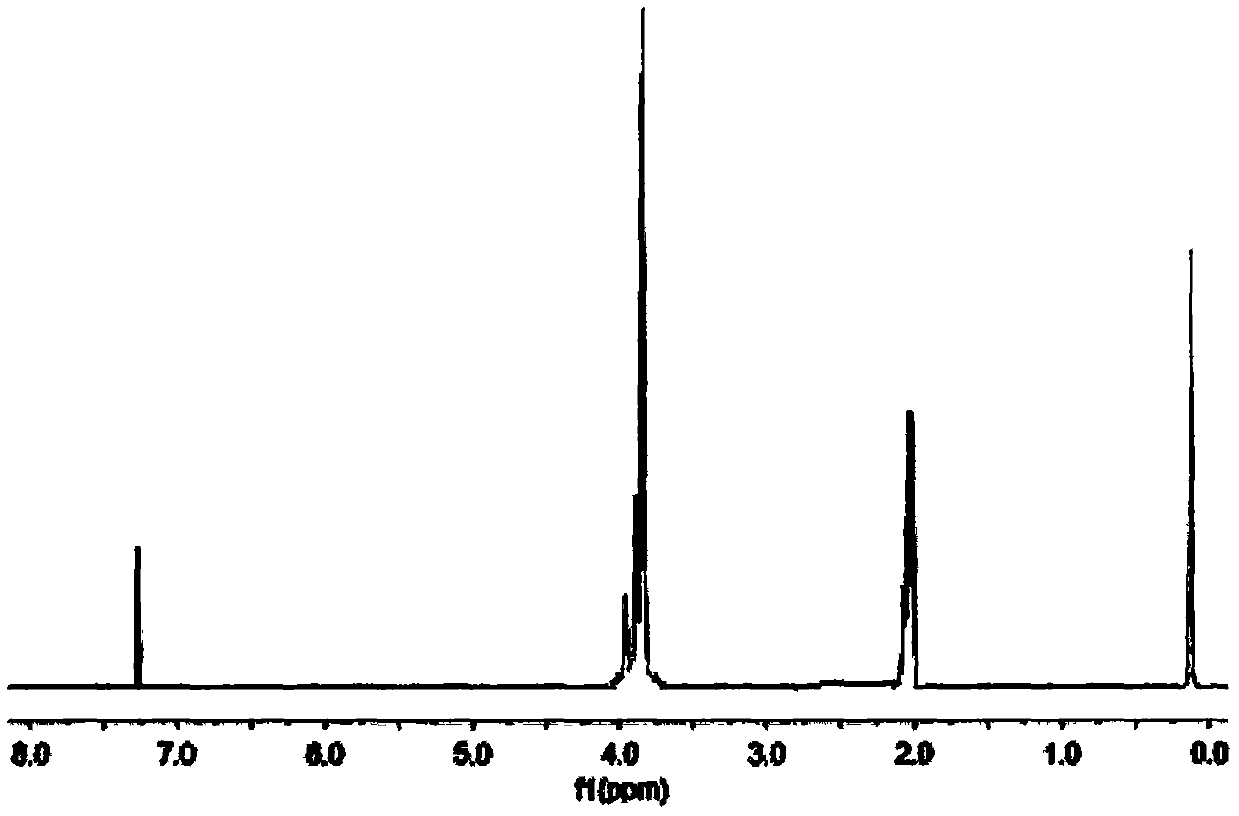

Method used

Image

Examples

Embodiment 1

[0022] Example 1 In a 100ml four-neck flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a drying tube and a hydrogen chloride absorption device at the upper mouth of the condenser, add 50ml of diethylene glycol dimethyl ether and 7.8g (0.05 mol) trihydroxymethylphosphorus sulfide, at 20°C, add 6.45g (0.05mol) dimethyldichlorosilane dropwise, the temperature during the dropwise addition should not exceed 40°C, after the dropping, heat up to 70°C for 1 hour, and keep warm for the reaction 5h, then heat up to 130°C, keep warm for 7h, distill off the solvent and a small amount of low boiling point substances under reduced pressure, cool down to 30°C, add 20 ml of water, add 5% sodium carbonate solution dropwise, adjust the system to pH = 7, statically Place, separate layers, remove the colorless transparent viscous liquid in the lower layer, and obtain the reactive flame retardant thiophosphonoheterocyclic silicate, and the product yield is 95.3%....

Embodiment 2

[0023] Example 2 In a 100ml four-necked flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a drying tube and a hydrogen chloride absorbing device at the upper mouth of the condenser, add 60ml of tetrachloroethane and 7.8g (0.05mol) of trichloride Hydroxymethylphosphorus sulfide, at 20°C, add 6.45g (0.05mol) of dimethyldichlorosilane dropwise, and control the temperature during the dropwise addition to not exceed 40°C. Raise the temperature to 140°C, keep it warm for 6 hours, distill off the solvent and a small amount of low boiling point substances under reduced pressure, cool down to 30°C, add 20 ml of water, add 5% sodium carbonate solution dropwise, adjust the system to pH = 7, let stand, and divide layer, and the lower layer was removed as a colorless transparent viscous liquid to obtain a reactive flame retardant thiophosphonoheterocyclic silicate with a product yield of 94.1%.

Embodiment 3

[0024] Example 3 In a 100ml four-necked flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a drying tube and a hydrogen chloride absorption device at the upper mouth of the condenser, add 40ml of ethylene glycol diethyl ether and 7.8g (0.05mol) Trihydroxymethylphosphorus sulfide, at 20°C, add 6.45g (0.05mol) of dimethyldichlorosilane dropwise, and control the temperature during the dropwise addition to not exceed 40°C. After the dropping, heat up to 70°C for 1 hour, and keep the temperature for 5 hours. Then heat up to 120°C, keep the temperature for 8 hours, distill off the solvent and a small amount of low boiling point substances under reduced pressure, cool down to 30°C, add 20 ml of water, add 5% sodium carbonate solution dropwise, adjust the system to pH=7, let it stand, Separate layers, and remove the lower layer of colorless transparent viscous liquid to obtain the reactive flame retardant thiophosphonoheterocyclic silicate, with a prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com