Processing method of high-strength iron tailings aerated concrete block

A technology of aerated concrete and processing method, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of complex process, unable to meet the needs of construction projects, long preparation period, etc., to reduce the preparation process, improve the Effect of scrap recycling efficiency and block preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

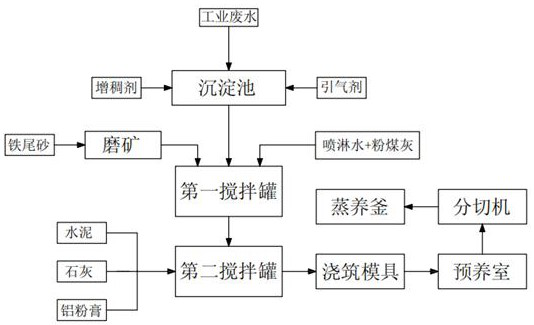

Image

Examples

Embodiment

[0050] (1) Preparation of finished product puree:

[0051] (1.1) Put the iron tailings into the grinding mill and grind until the fineness of the iron tailings is 0.09 mm;

[0052] (1.2) Discharge the milled iron tailings and wet ash mixture in the ratio of 4:1 into the first mixing tank for stirring and mixing to make primary puree; The fine ash collected in the air is a kind of solid waste in the factory area. When cleaning, it needs to be treated by spraying method, which is the wet ash discharge method, and the discharged liquid is the wet ash discharge mixture. The ratio between water and fly ash is 1:20;

[0053] (1.3) Add the adjusted pulp to the primary raw pulp to obtain the finished raw pulp, the mixing ratio between the primary raw pulp and the adjusted pulp is 9:1, and stir the finished raw pulp until the diffusion degree is 30cm; the adjusted pulp includes ;The industrial waste liquid is discharged into the sedimentation tank, and after filtration and sedimentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com