Dried material package moisture prevention and absorption device

A material and anti-absorption technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of excessive water content of chemical raw materials, failure to meet production and use requirements, etc., to achieve simple structure, improve quality, Design novel and unique effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

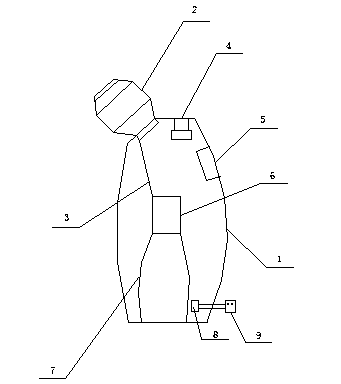

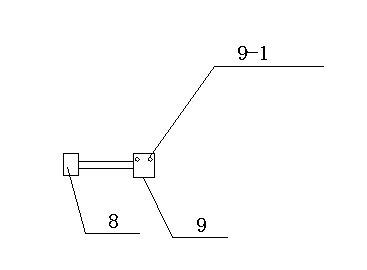

[0009] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: it includes a closed protective cover body 1, a dryer 2, a material guide plate 3, a heating and drying device 4, an observation window 5, a crusher 6, a material bag 7, a humidity sensor 8 and an alarm 9, the upper end of the airtight protective cover body 1 is sealed and connected to the bottom of the dryer 2, a material guide plate 3 is arranged between the dryer 2 and the crusher 6, and a material bag 7 is arranged below the crusher 6, and the airtight protective cover A heating and drying device 4 is arranged above the body 1, an observation window 5 is arranged on the outer wall of the airtight protective cover body 1, and a humidity sensor 8 is arranged on the lower side of the airtight protective cover body 1, and the humidity sensor 8 is connected to an alarm 9 .

[0010] The alarm 9 is provided with an alarm lamp 9-1.

[0011] This specific embodiment has the following b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com