Recovery system and recovery method for recovering titanium and tungsten powder from waste scr catalyst

The technology of SCR catalyst and recovery method is applied in the recovery system and recovery field of recovering titanium and tungsten powder from waste SCR catalyst, which can solve the problems of environmental pollution, waste of resources, deactivation of SCR catalyst, etc., and achieve high recovery efficiency and resource saving. , Improve the effect of resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

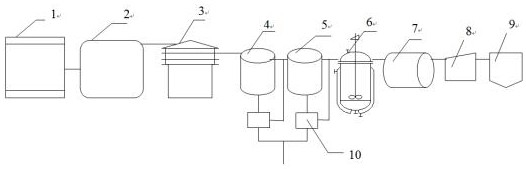

[0081] The recovery method that reclaims titanium-tungsten powder from waste SCR catalyst comprises the steps:

[0082] After the fly ash on the surface of the spent SCR catalyst is sucked by the dust suction treatment device 1, it is physically crushed in the coarse crushing treatment device 2, coarsely crushed to a sheet shape of 8 mm × 8 mm, and transported to the screening treatment device 3 by a conveyor belt. The sub-processing device 3 is fully enclosed, and there is a groove for receiving free fly ash below, and the sieving screen is 200 mesh.

[0083] The sieved flake material enters the initial cleaning treatment device 4, which is equipped with ultrapure water and cleaning aids. The concentration of cleaning aids is 0.001% of the mass of the material, and the leaching time is 30 minutes. The material after the initial cleaning treatment device 4 enters the deep cleaning treatment device 5. There is a deep cleaning liquid in the device, and the mass ratio of the mate...

Embodiment 2

[0086] The recovery method that reclaims titanium-tungsten powder from waste SCR catalyst comprises the steps:

[0087] After the fly ash on the surface of the spent SCR catalyst is sucked by the dust suction treatment device 1, it is physically crushed in the coarse crushing treatment device 2, coarsely crushed to a sheet shape of 15 mm × 15 mm, and transported to the screening treatment device 3 by a conveyor belt, and then sieved. The sub-processing device 3 is fully enclosed, and there is a groove for receiving free fly ash below, and the sieving screen is 100 mesh.

[0088] The sieved flake material enters the initial cleaning treatment device 4, which contains ultrapure water and cleaning aids. The concentration of the cleaning aids is 0.003% of the mass of the material, and the leaching time is 10 minutes. The material after the initial cleaning treatment device 4 enters the deep cleaning treatment device 5. There is a deep cleaning liquid in the device, and the mass ra...

Embodiment 3

[0091] The recovery method that reclaims titanium-tungsten powder from waste SCR catalyst comprises the steps:

[0092] After the fly ash on the surface of the spent SCR catalyst is sucked by the dust suction treatment device 1, it is physically crushed in the coarse crushing treatment device 2, coarsely crushed to a sheet shape of 10mm×10mm, and transported to the screening treatment device 3 by a conveyor belt. The sub-processing device 3 is fully enclosed, and there is a groove for receiving free fly ash below, and the sieving screen is 150 mesh.

[0093] The sieved flake material enters the initial cleaning treatment device 4, which contains ultrapure water and cleaning aids. The concentration of the cleaning aids is 0.002% of the mass of the material, and the leaching time is 20 minutes. The material after the initial cleaning treatment device 4 enters the deep cleaning treatment device 5. There is a deep cleaning liquid in the device, and the mass ratio of the material t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com