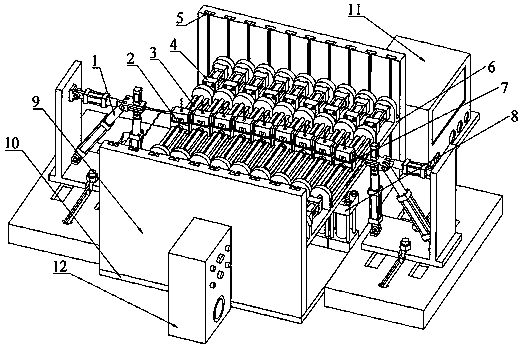

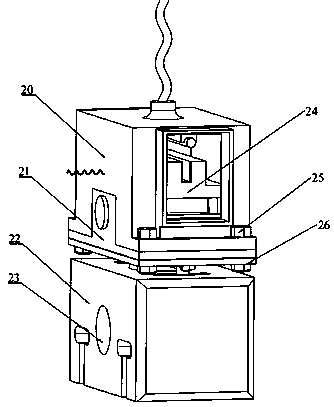

Multi-point three-dimensional electrothermal drawing-pressing composite bending forming device based on independent heat preservation mode

A bending forming and three-dimensional technology, which is applied in the field of thermal stretch bending forming devices for profiles, and in the field of multi-point three-dimensional electric heating stretch-compression composite bending forming devices, can solve problems such as difficult three-dimensional thermal stretch bending forming, achieve precise forming, and improve plasticity , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, three-dimensional electrothermal drawing-compression compound bending forming process of a rectangular cross-section profile.

[0028] The first step is to determine the number of basic bodies used, the height and position parameters of the basic bodies, the installation position of the bending cylinder on each basic body, and the movement displacement of the piston rod of each bending cylinder according to the geometric shape parameters of the target part. First, adjust the shape of each basic body to the same horizontal plane through the lifting cylinder, and adjust the shape of each mold unit on the basic body to the same straight line by controlling each bending cylinder, and complete the initialization of the shape adjustment of the mold unit.

[0029] In the second step, the metal profiles are penetrated from each incubator, and the two ends with insulating materials are clamped by clamps. Then, the self-resistance heating of the profile and the resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com