A titanium dioxide-supported ruthenium catalyst for the selective hydrogenation of benzene to cyclohexene and its preparation method

A selectivity and catalyst technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of agglomeration deactivation, large amount of precious metal Ru, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

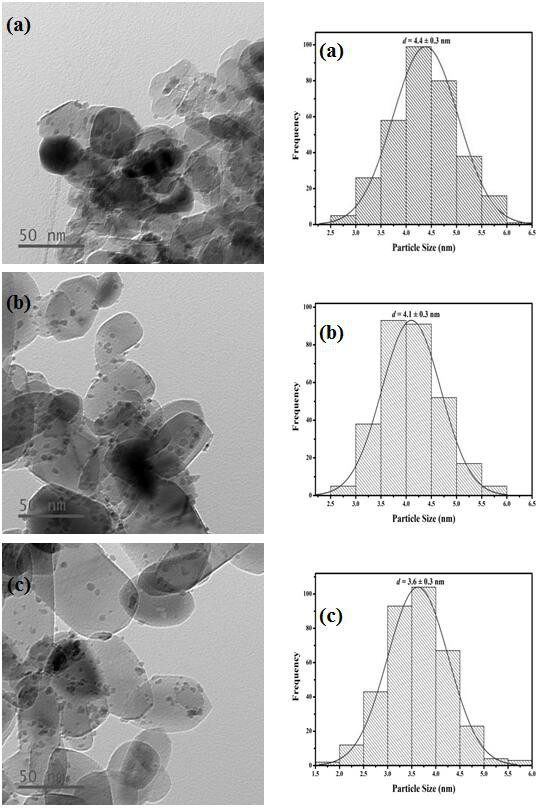

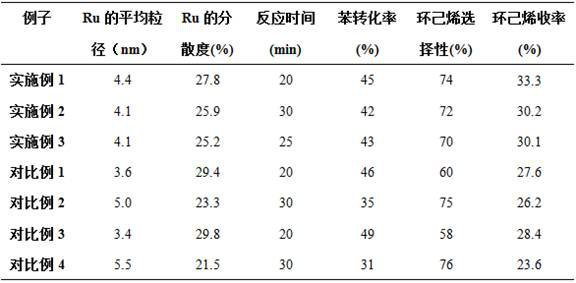

Embodiment 1

[0026] Weigh 0.61 g RuCl 3 ·3H 2 O and made into a solution with a concentration of 0.40 mol / L, and then added 4.0 g of a three-neck round-bottomed flask that had been heat-treated at 680°C and had a specific surface area of 45 m2 / g, anatase TiO with a most probable pore diameter of 22 nm 2 Carrier, then Ru salt solution was added dropwise into a three-neck flask, and then 80 mL of deionized water was added to mix well, and mechanically stirred at a speed of 300 r / min for 3.5 h. Then weigh 0.32 g NaBH 4 And make a solution with a concentration of 0.4 mol / L, and then add it dropwise to the above mixed solution to fully react. After the reaction was complete, the agitation was stopped, and the black precipitate was taken out, then washed by centrifugation and dried in vacuum to obtain Ru / TiO with a Ru loading of 5 wt%. 2 catalyst.

Embodiment 2

[0028] Except that the carrier mentioned in Example 1 is replaced by one that has been heat-treated at 650°C, the specific surface area is 48 m 2 / g, anatase TiO with a most probable pore diameter of 21 nm 2 Except for the carrier, the rest of the synthesis details are consistent with Example 1.

Embodiment 3

[0030] Except that the carrier mentioned in Example 1 is replaced by one that has been heat-treated at 600°C, the specific surface area is 55 m 2 / g, anatase TiO with a most probable pore size of 18 nm 2 Except for the carrier, the rest of the synthesis details are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com