Battery monitoring method and system

A battery monitoring and battery technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of low safety and poor accuracy of monitoring data, and achieve the effect of improving safety, improving accuracy, and not being easy to short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a battery monitoring method. In this embodiment, the battery is a lithium power battery used in new energy vehicles, but the battery type is not specifically limited, and different types of batteries can be monitored according to actual conditions. .

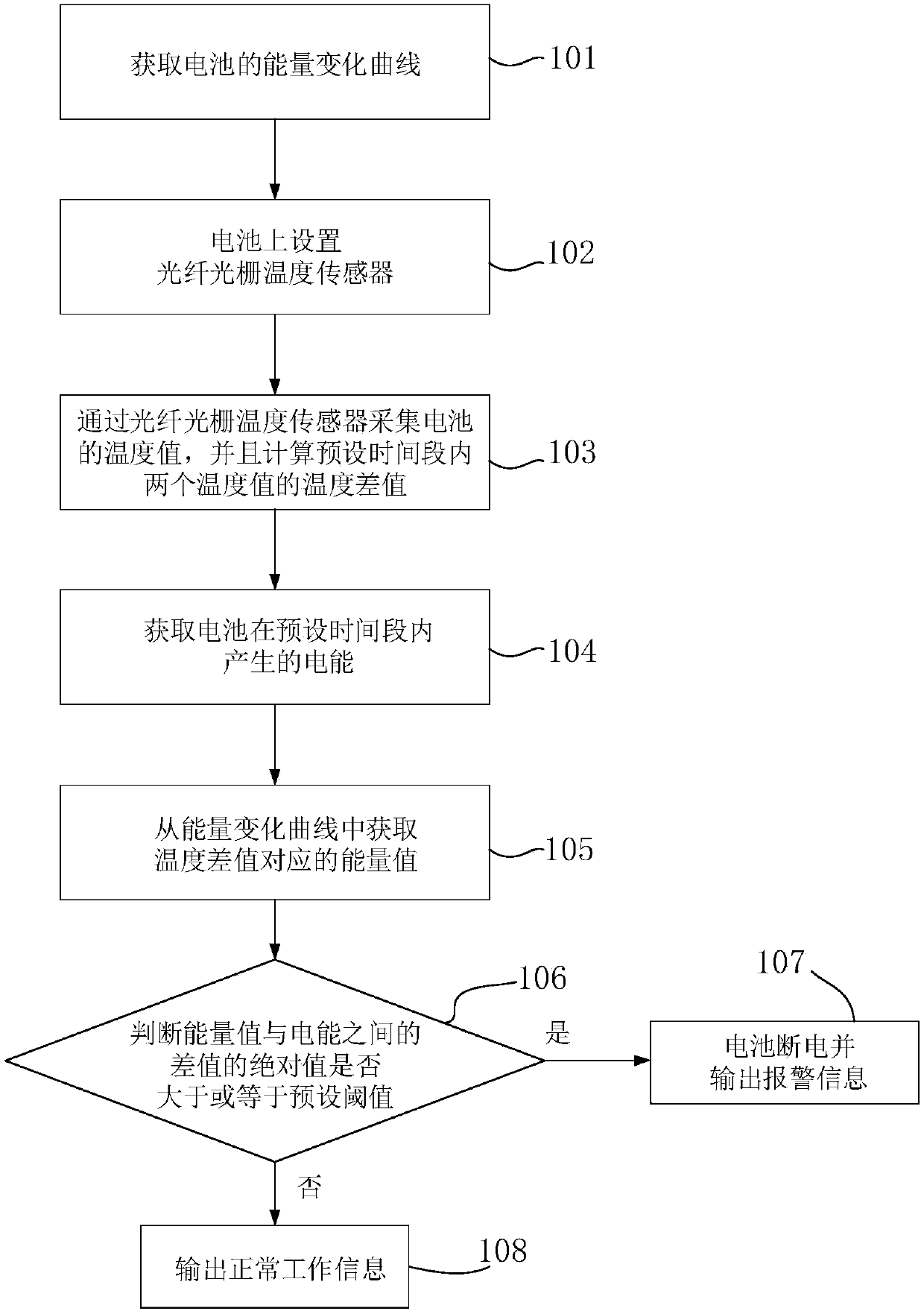

[0045] Such as figure 1 As shown, the battery monitoring method includes the following steps:

[0046] Step 101, acquiring the energy change curve of the battery.

[0047] In this step, the energy change curve of the battery is acquired and stored in advance, the energy change curve is used to characterize the energy change of the battery when charging or discharging in an ideal state, and each energy value of the energy change curve is related to There is a one-to-one correspondence between a temperature difference of the battery.

[0048] Step 102, installing a fiber grating temperature sensor on the battery.

[0049] In this embodiment, the battery includes several battery cells, and the nu...

Embodiment 2

[0068] This embodiment provides a battery monitoring system. In this embodiment, the battery is a lithium power battery used in new energy vehicles, but the battery type is not specifically limited, and different types of batteries can be monitored according to actual conditions. .

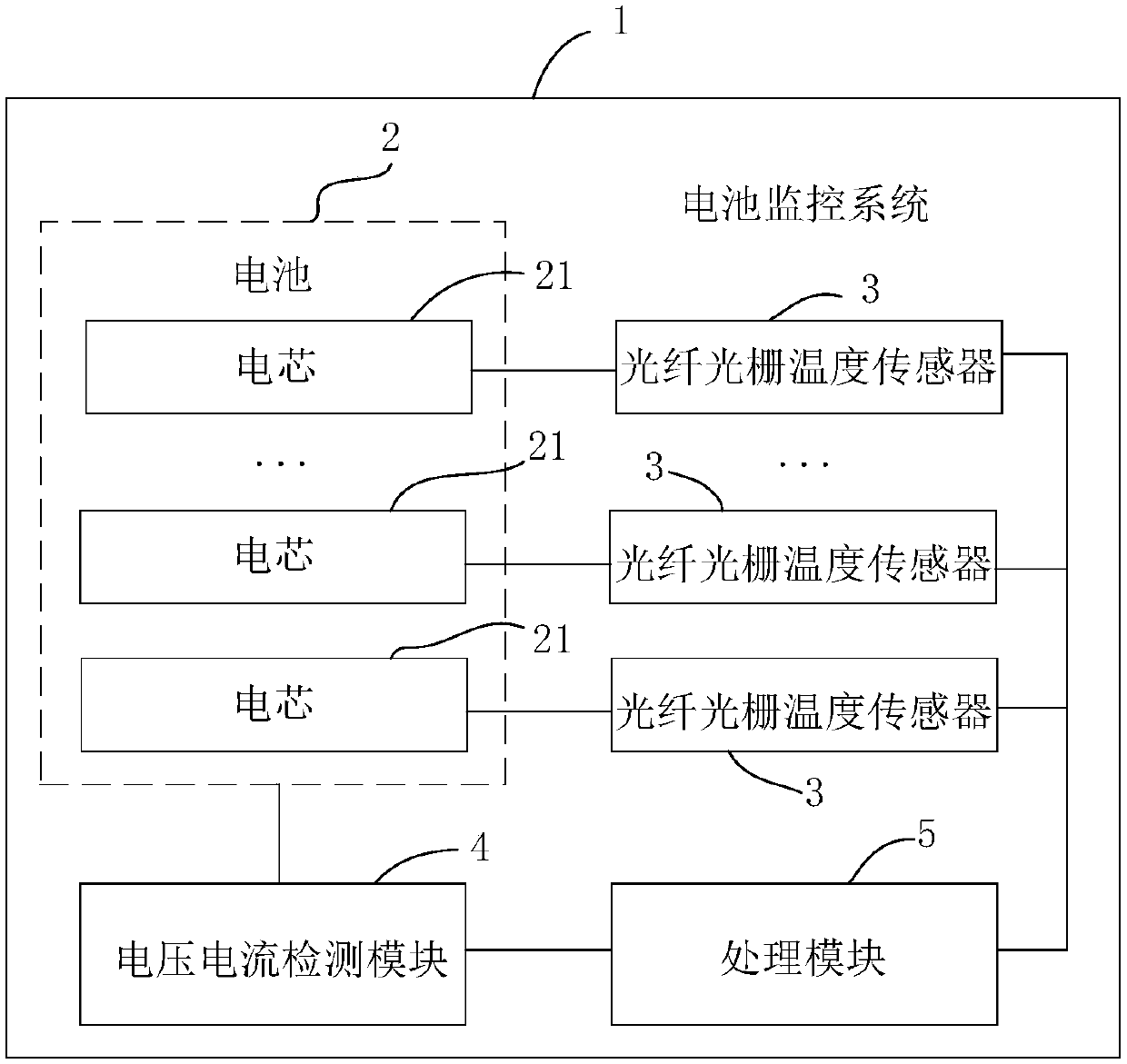

[0069] Such as figure 2 As shown, the battery monitoring system 1 includes a battery 2, a number of fiber grating temperature sensors 3, a voltage and current detection module 4 and a processing module 5, and the battery 2 includes a number of battery cells 21. In this embodiment, the battery cells are not specifically limited. and the number of fiber grating temperature sensors can be determined according to the actual situation.

[0070] A plurality of fiber grating temperature sensors are installed on the electrode positions on the surface of each cell, and the accuracy of the test data can be improved by setting the fiber grating temperature sensors on the electrode positions on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com