Check bolt assembly

A technology of anti-loosening bolts and components, which is applied in the field of mechanical parts structure, can solve the problems of loose connection and low manufacturing precision, and achieve the effect of ensuring stability, low manufacturing precision requirements, and strong locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

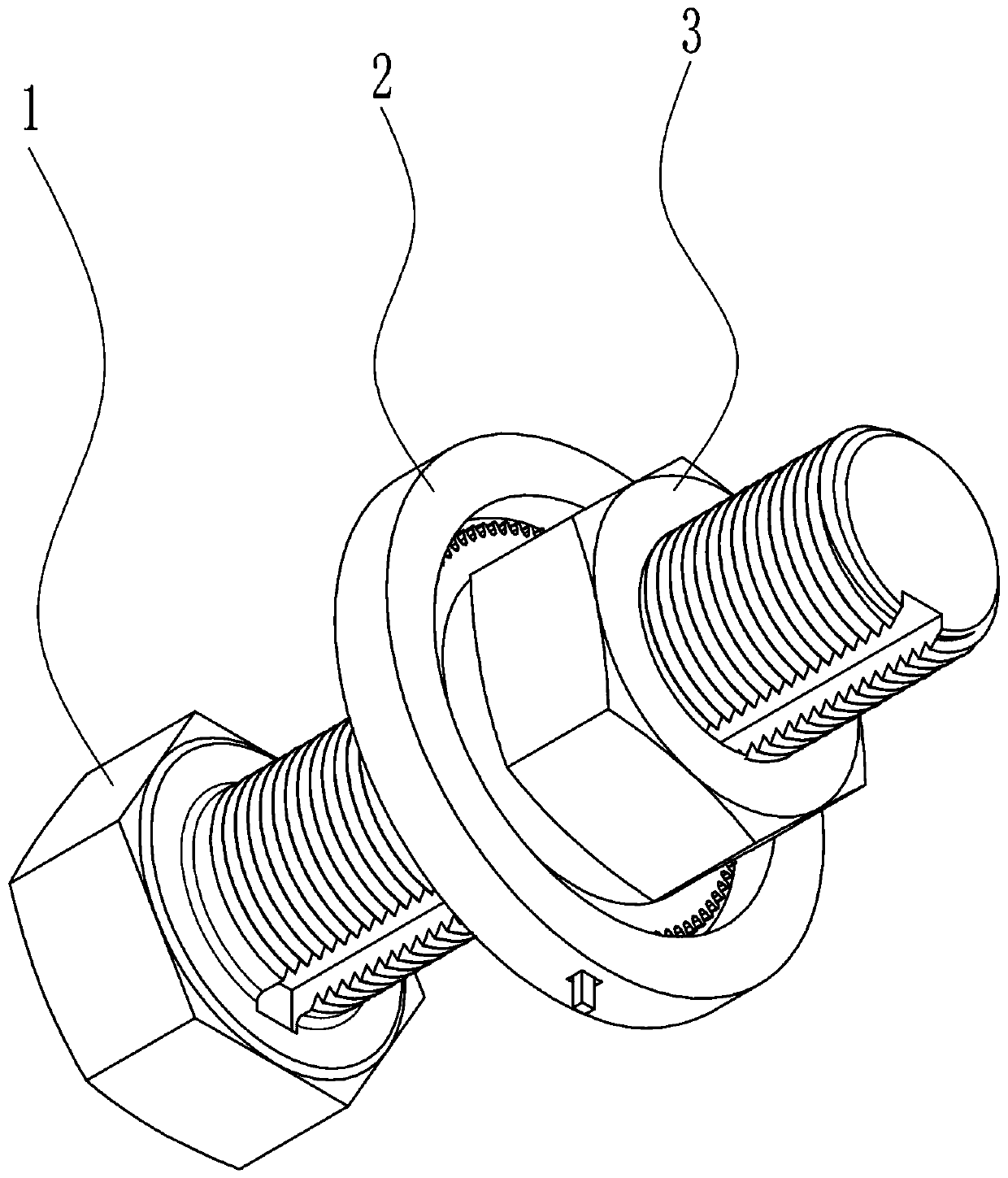

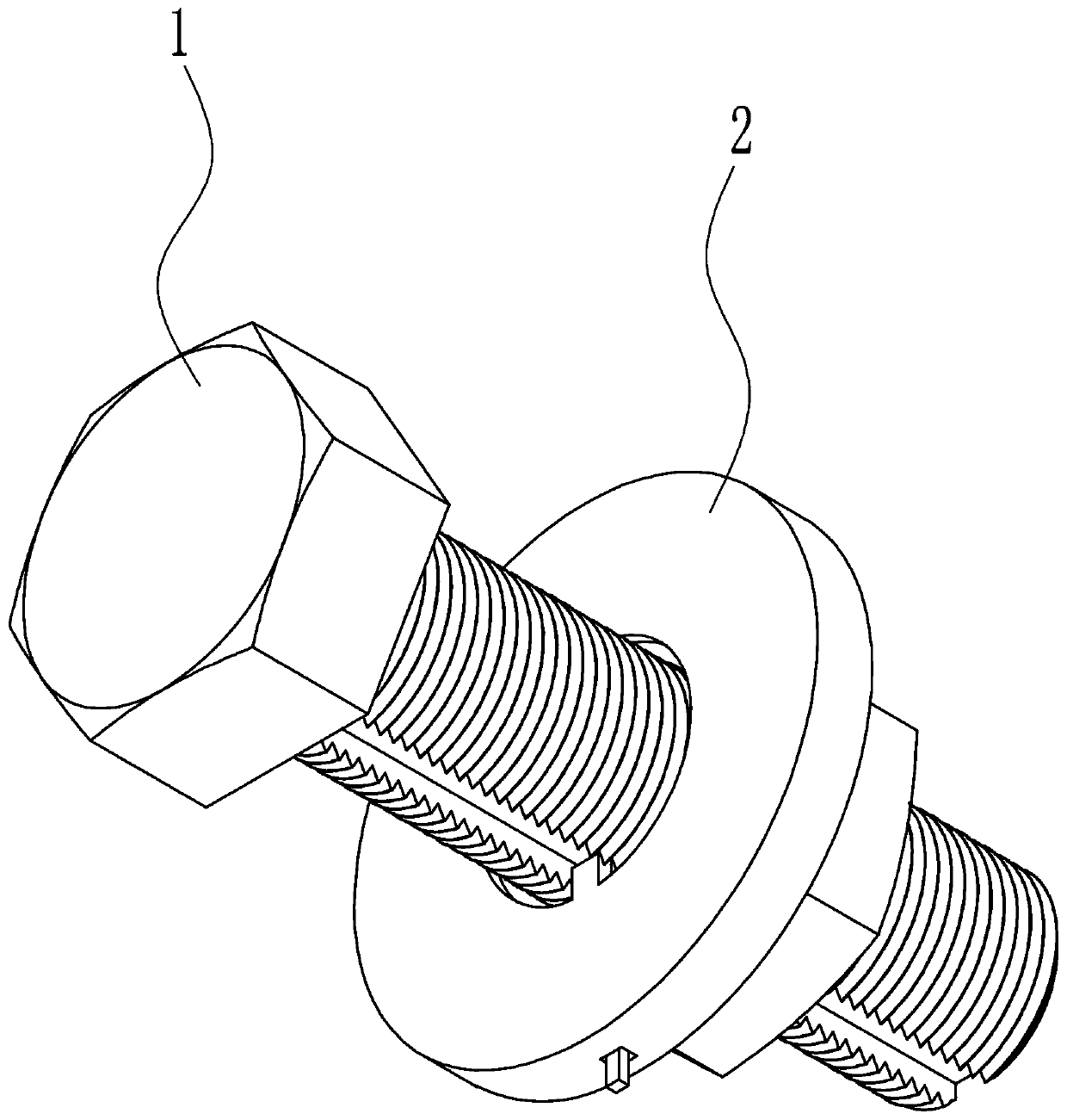

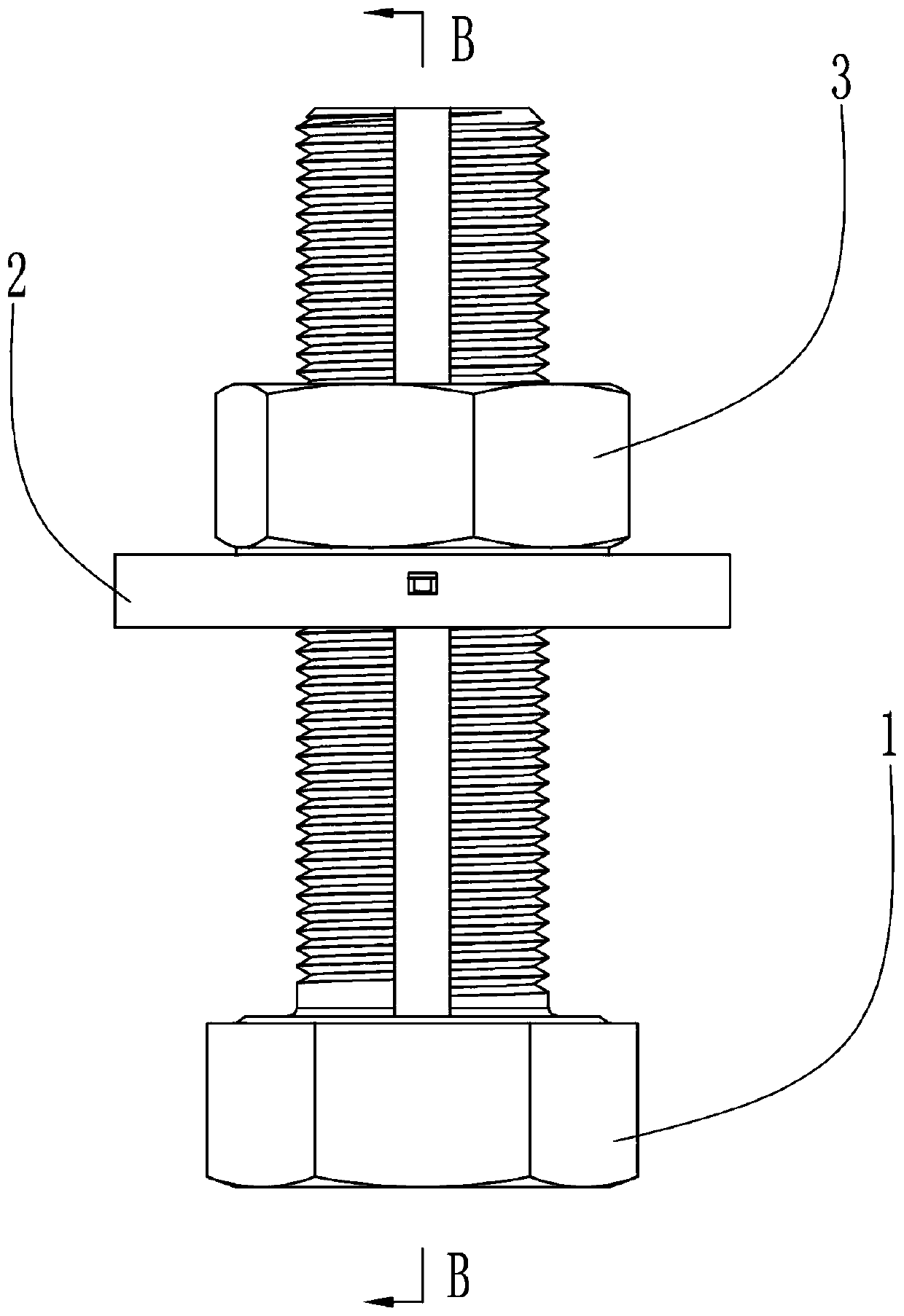

[0028] This embodiment is a connection structure of anti-loosening bolts, such as Figure 1-Figure 6 as shown, figure 1 is the three-dimensional structure diagram of the connection structure under one viewing angle, figure 2 is the three-dimensional structure diagram of the connection structure under another viewing angle, image 3is the front view of the connection structure, Figure 4 for image 3 The B-B sectional view, Figure 5 is the three-dimensional structure diagram of the locking nut in the connection structure, Figure 6 It is a three-dimensional structure diagram of the locking washer in the connection structure. The connection structure of the anti-loosening bolt includes a locking bolt 1, a locking washer 2 and a locking nut 3. The locking bolt 1 is threaded with a locking nut 3, and a locking washer 2 and a locking nut 3 are arranged between the locking bolt 1 and the locking nut 3. Fitted with the lock washer 2, wherein the lock bolt 1 has a lock groove ...

Embodiment 2

[0031] This embodiment is also a connection structure of anti-loosening bolts, which is similar to the above-mentioned connection structure, except that the compression spring 25 is changed to an ordinary spring, so that the pulling and rebounding effect of the locking block 24 is relatively poor, but it does not It affects its use; at the same time, in this embodiment, the raised wall 22 is only distributed on the outer edge of the locking washer 2, that is, the raised wall 22 is only provided on a certain part of the outer edge of the locking washer 2, and the raised wall 22 is raised there. The wall 22 has a wall hole 23, and a locking block 24 and a common spring are provided, so that the effect and function of the structure can be fully realized, but the overall strength of the locking washer 2 is not as high as that of the whole ring, but it does not affect the structure at all. use and stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com