Diamond coated drill

A drill bit and diamond technology, applied in the field of diamond coated drill bits, can solve the problems of easy blockage of the self-priming device, inconvenient cleaning, and easy blockage in the small area inside the drill bit, etc., to prolong the service life, prevent blockage, and reduce the phenomenon of drill drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

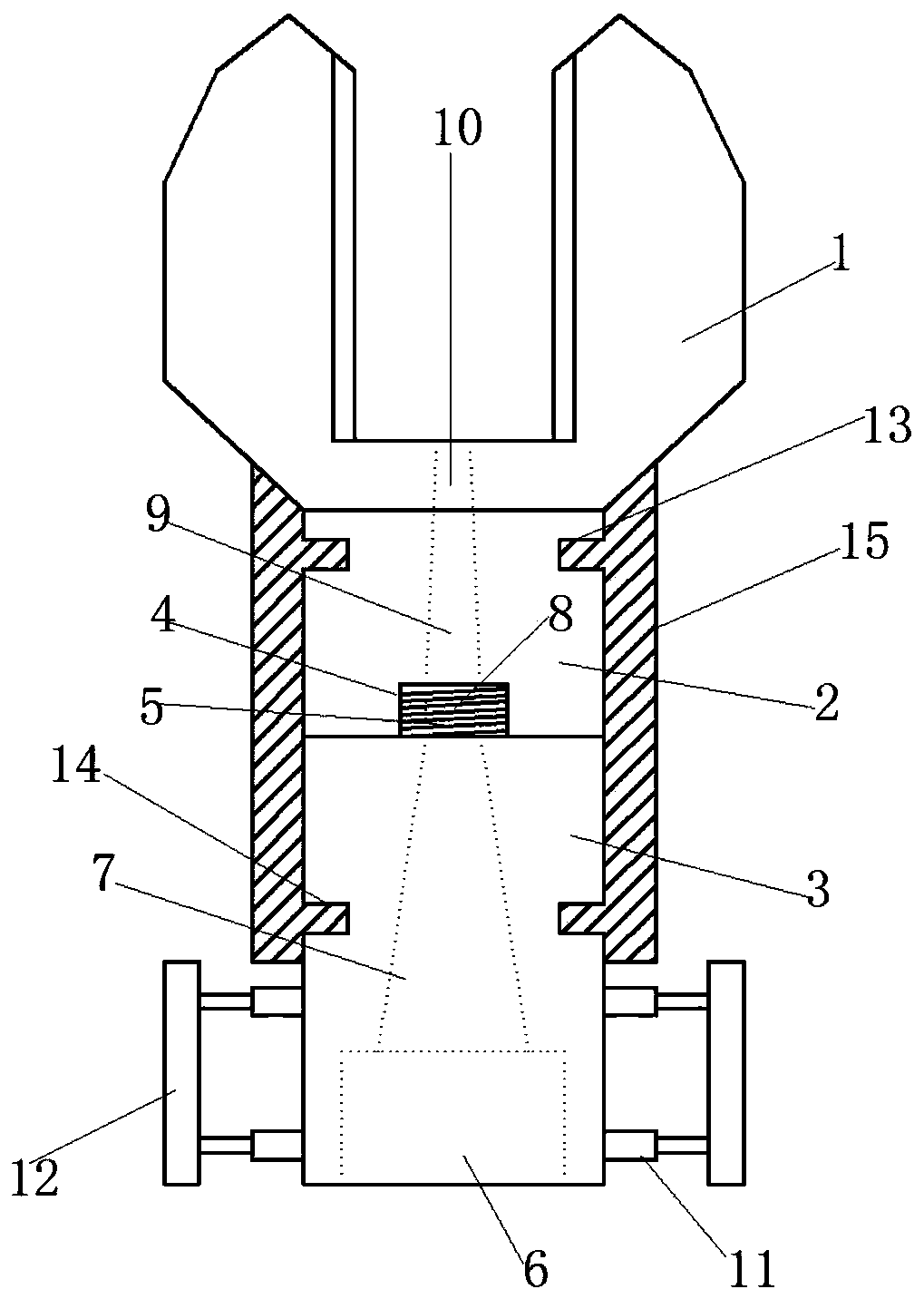

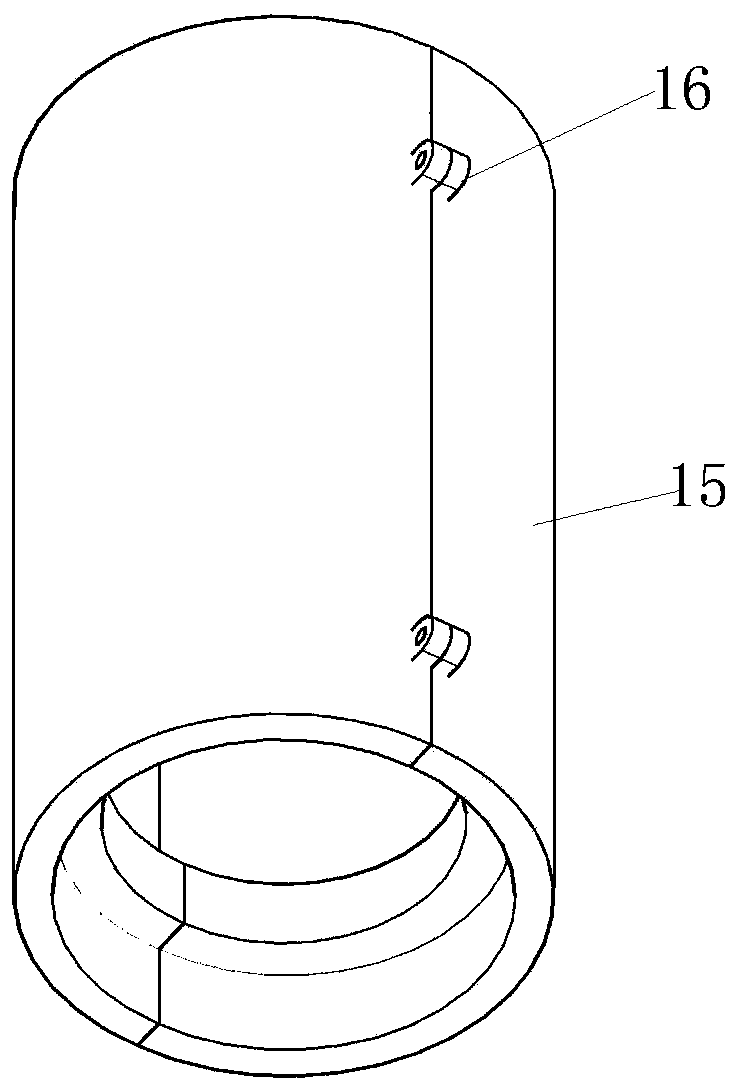

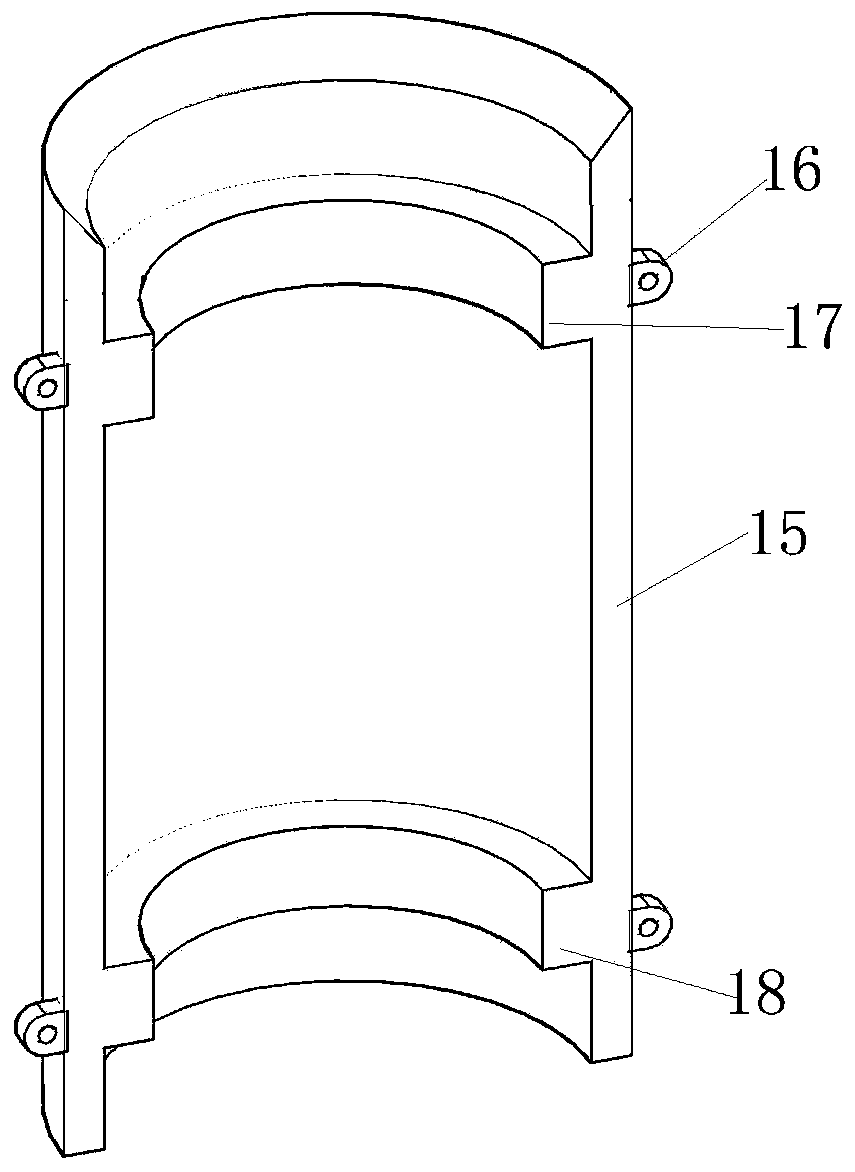

[0023] Such as Figure 1-3 In the shown embodiment, a diamond-coated drill bit includes a crushing head 1, a first connecting end 2 integrally formed with the crushing head 1 and located at the lower end of the crushing head 1, and a second connecting end 3 arranged at the lower end of the first connecting end 2 And the reinforcement mechanism arranged at the lower part of the side of the second connecting end 3; the crushing head 1 is symmetrically provided with a plurality of crushing teeth; the bottom surface of the first connecting end 2 is provided with an internal thread groove 4, and the second connecting end 3 The bottom surface is provided with an ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com