Coal mill with dustproof function for thermal power plant

A technology for thermal power plants and coal mills, applied in the field of coal mills, can solve the problems of high temperature and large amount of dust, and achieve the effects of less oxygen content, difficult pulverized coal combustion, and less oxygen content in the fuselage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

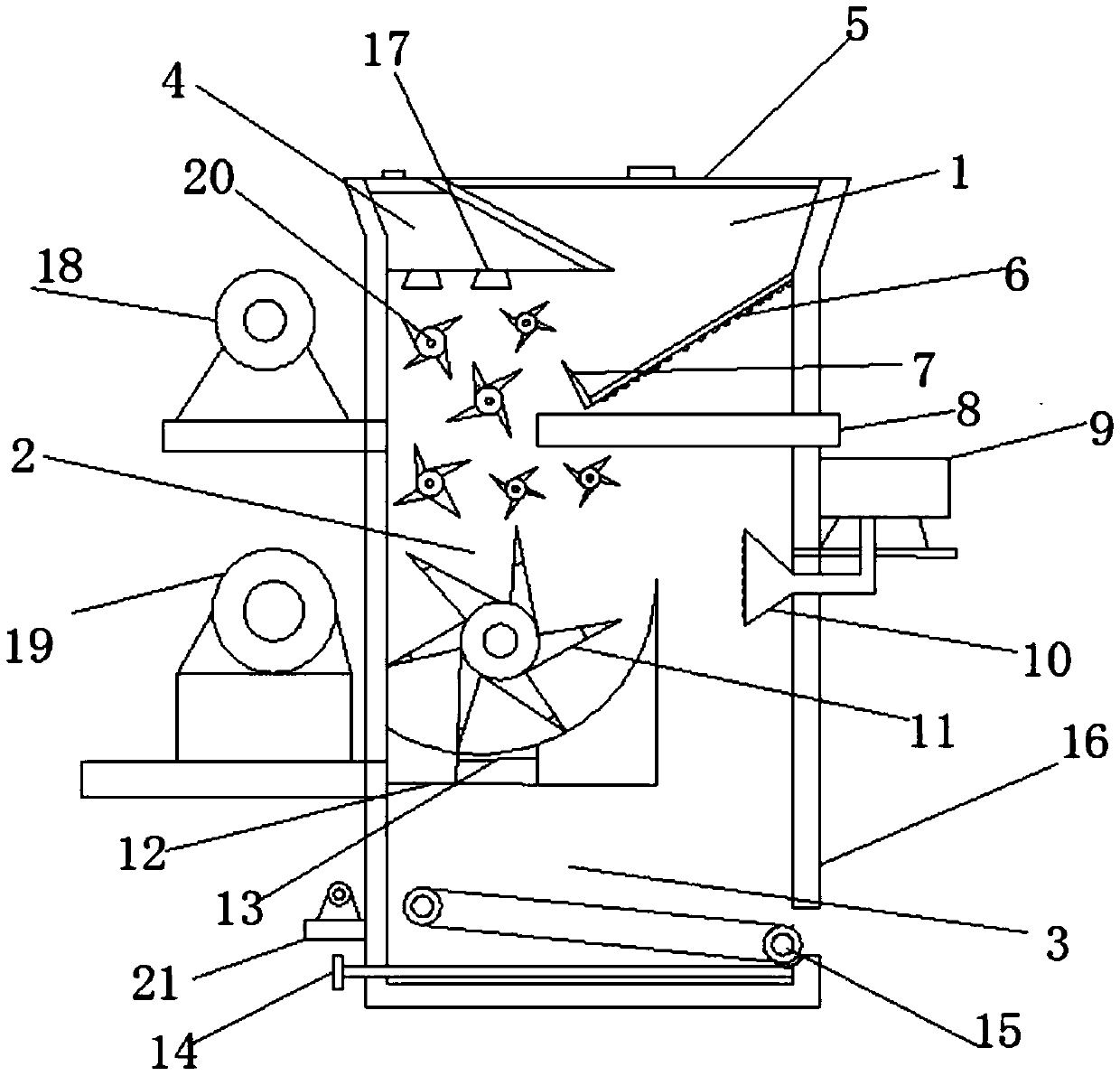

[0014] refer to figure 1 , a coal mill with dust-proof function for thermal power plants, including a fuselage 16, a feed bin 1, a spray chamber 4, a crushing bin 20 and a discharge bin 3, and the inside of the fuselage 16 is respectively equipped with an inlet and outlet from top to bottom. Feed bin 1, spray chamber 4, crushing bin 20, and discharge bin 3, top cover 5 is provided on feed bin 1, sieve plate 6 is provided on feed bin 1, and sieve plate 6 is obliquely fixed on machine body 16 , the sieve plate 6 plays the role of dust removal for the first time, the other end of the sieve plate 6 is provided with a baffle 7, the baffle 7 is a rubber baffle and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com