Preparation method and application of perovskite solar cell electron transport layer based on low-temperature titanium dioxide mesoporous structure

An electron transport layer and solar cell technology, which is applied in the field of solar cells, can solve the problems of limited application and high energy consumption, and achieve the effects of collection and transmission, low energy consumption, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a method for preparing an electron transport layer of a perovskite solar cell based on a low-temperature titanium dioxide mesoporous structure. The specific steps are as follows:

[0028] 1) Preparation of TiO on conductive glass substrate 2 dense layer

[0029] Preparation of precursor TiCl 4 The alcohol solution was spin-coated on a homogenizer, and then placed on a heating table for annealing.

[0030] 2) on TiO 2 Preparation of TiO on the surface of dense layer 2 Mesoporous layer

[0031] Preparation of brookite phase TiO 2 The alcohol dispersion of the slurry is spin-coated on a homogenizer, and then placed on a heating table for annealing.

[0032] TiCl 4 Alcoholic solution and brookite phase TiO 2 In the alcohol dispersion of the slurry, the alcohol solvent can be selected from n-butanol, ethanol, and isopropanol.

[0033] Preparation of TiO on Conductive Glass Substrates 2 When dense layer, the present invention selects T...

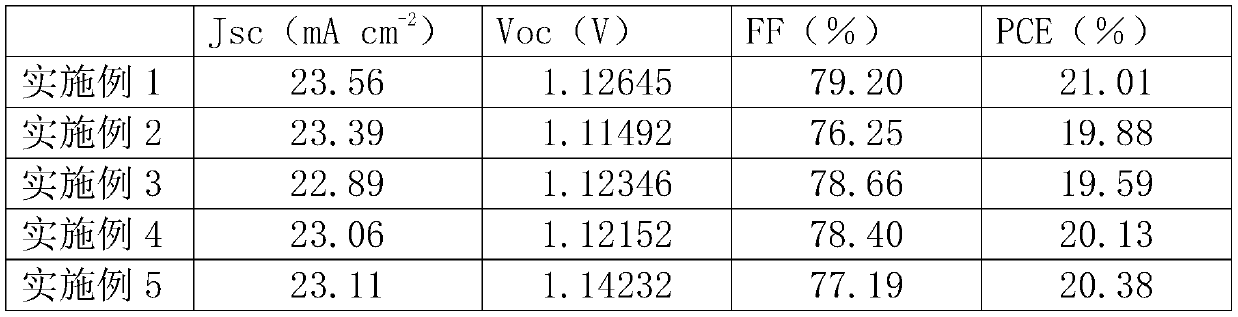

Embodiment 1

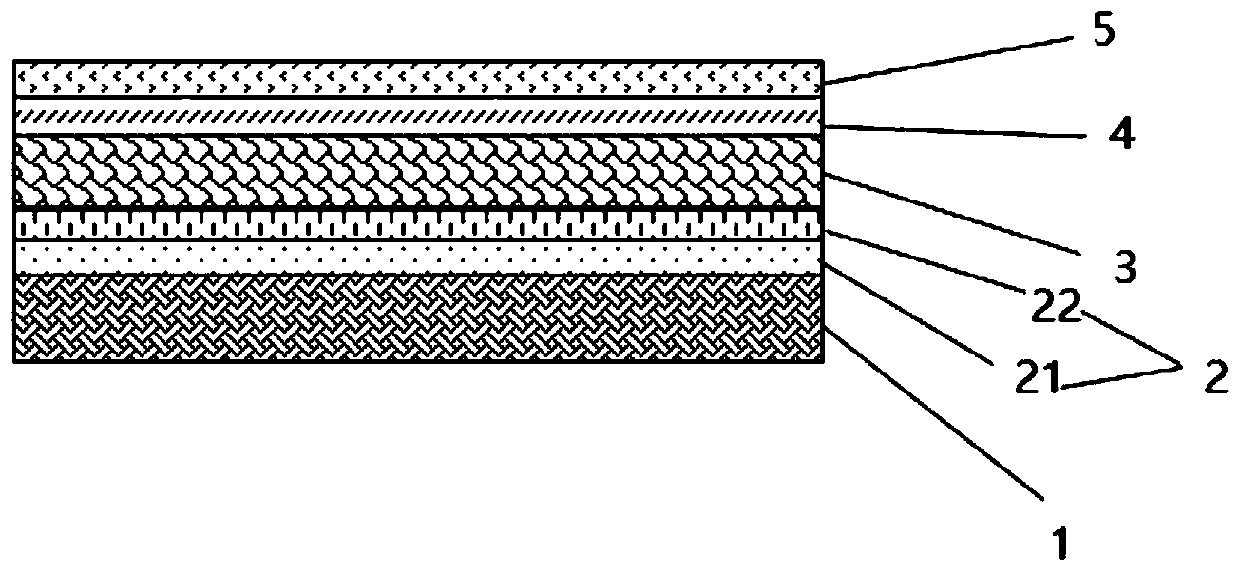

[0044] Such as figure 1 The perovskite solar cell structure shown includes a transparent conductive layer, an electron transport layer, a perovskite absorber layer, a hole transport layer and a back electrode layer. The specific preparation method is as follows:

[0045] 1) Prepare the FTO conductive glass layer by chemical vapor deposition on the glass substrate;

[0046] 2) Prepare an electron transport layer on the FTO conductive glass substrate, wherein the electron transport layer includes TiO 2 dense layer and TiO 2 Mesoporous layer:

[0047] ① Preparation of TiO on FTO conductive glass substrate 2 dense layer

[0048] 17% TiCl 4 The original solution was dissolved in n-butanol and configured as TiCl with a concentration of 0.18mol / L 4 - Isopropanol solution. The cleaned FTO conductive glass is placed on the homogenizer, and the TiCl 4 -N-butanol solution is uniformly spin-coated on the surface of FTO glass, the spin-coating time is 30s, and then the 2 The dense...

Embodiment 2

[0055] Such as figure 1 The perovskite solar cell structure shown includes a transparent conductive layer, an electron transport layer, a perovskite absorber layer, a hole transport layer and a back electrode layer in sequence. The specific preparation method is as follows:

[0056] Except step 2), other steps are identical with embodiment 1;

[0057] 2) Prepare an electron transport layer on the FTO conductive glass substrate, wherein the electron transport layer includes TiO 2 dense layer and TiO 2 Mesoporous layer:

[0058] ① Preparation of TiO on FTO conductive glass substrate 2 dense layer

[0059] 17% TiCl 4 The original solution was dissolved in n-butanol and configured as TiCl with a concentration of 0.2mol / L 4 - Solution in n-butanol. The cleaned FTO conductive glass is placed on the homogenizer, and the TiCl 4 -N-butanol solution is uniformly spin-coated on the surface of FTO glass, the spin-coating time is 30s, and then the 2 The dense layer of FTO glass is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The size of granule | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com