Magnetic field assisted chemical etching device and method

A chemical etching and magnetic field-assisted technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as high cost, limited application range, and complicated operation, and achieve low cost, improved etching rate, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a device for magnetic field-assisted chemical etching, including a solution bottle 1 to accommodate the etching solution and the material to be etched 2, which is arranged outside the solution bottle 1 to provide a stable magnetic field for magnetic field excitation device, the magnetic field excitation device is two magnets 3 with opposite polarities arranged oppositely, and the magnets 3 are composed of permanent magnets.

[0039] A method for magnetic field-assisted chemical etching utilizing the above-mentioned device, comprising:

[0040] S1. Take a semiconductor material with a size of Φ100mm×200μm. The semiconductor material is a GaAs semiconductor substrate. Use a DY-220SP polishing machine and a DY-220SG grinding machine to polish the substrate, and then use deionized water and acetone to ultrasonically clean it for 5 minutes. , with N 2 blow dry. After the substrate was cleaned and dried, it was placed on an ATJ-100 coater, and AZ926...

Embodiment 2

[0044] The magnetic field-assisted chemical etching is performed using a device similar to that of Example 1, except that the magnet is composed of an electromagnetic coil.

[0045] The magnetic field assisted chemical etching is carried out in a method similar to that of Example 1, the difference is that in the S1 step, the semiconductor material used is composed of a GaAs semiconductor substrate and a GaAs epitaxial layer, wherein the GaAs epitaxial layer covers the GaAs semiconductor substrate the upper surface of the sheet; in the S2 step, inject H into the solution bottle 3 PO 4 、H 2 o 2 、H 2 O: 300ml of etching solution with a volume ratio of 0.5:2:25; the adjusted magnetic field strength is 1.5kOe, and the direction of the magnetic field faces the bottom of the solution bottle and is at 45 degrees to the bottom of the solution bottle.

[0046] The material obtained after etching was taken out, rinsed with deionized water for 2 min, and then washed with N 2 Blow dry...

Embodiment 3

[0048] The same apparatus as in Example 1 was used for magnetic field assisted chemical etching.

[0049] Carry out magnetic field-assisted chemical etching in a method similar to Example 1, the difference is that, in the S2 step, inject H into the solution bottle 3 PO 4 、H 2 o 2 、H 2 O is 300ml of etching solution with a volume ratio of 1:1:35; the adjusted magnetic field strength is 2kOe.

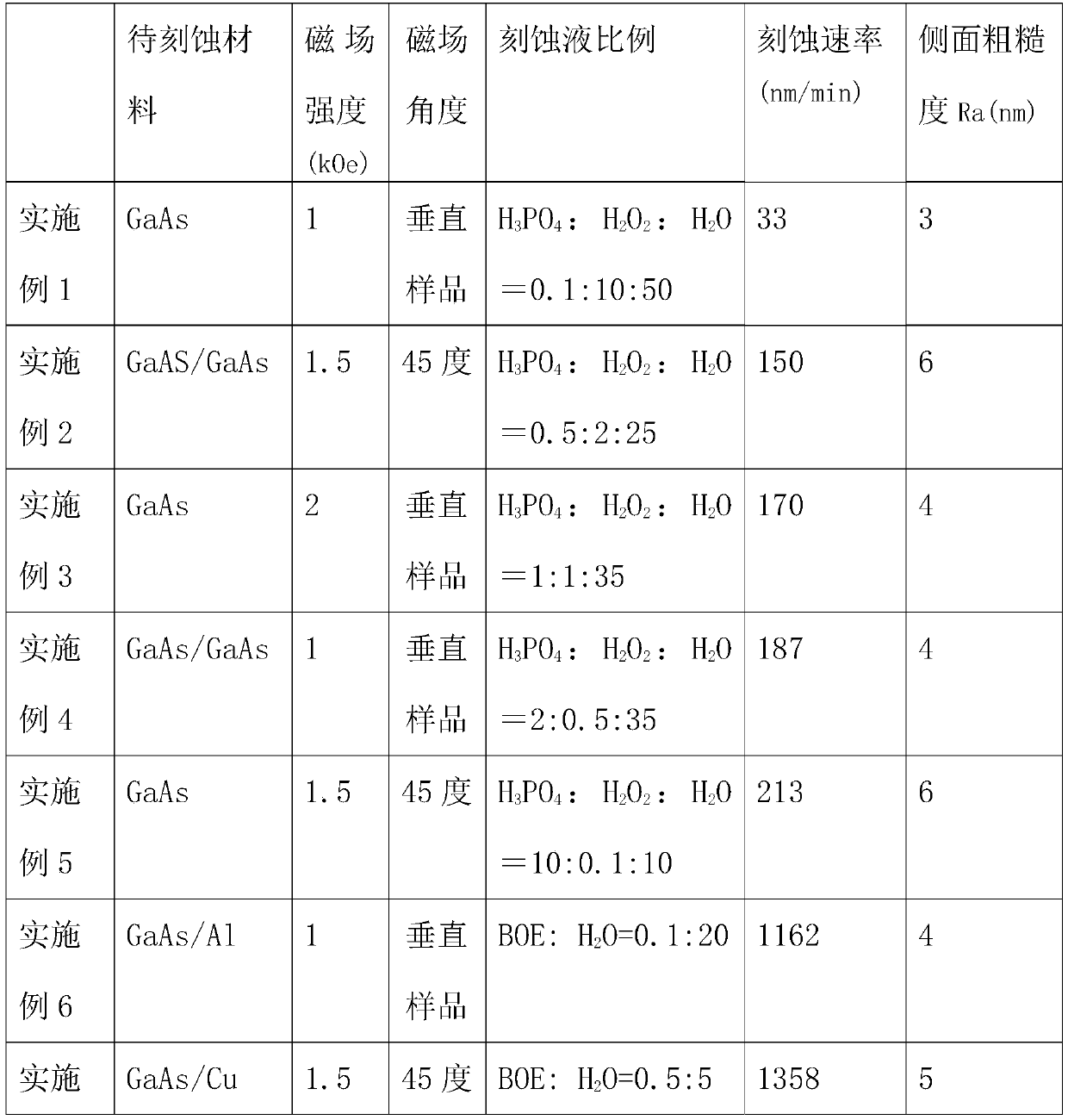

[0050] The material obtained after etching was taken out, rinsed with deionized water for 2 min, and then washed with N 2 Blow dry, use the ZYGO optical interferometer test system, measure the etching depth and the side roughness of the remaining pattern after etching, and calculate the etching rate. The obtained etch rate and the roughness results of the side of the retained pattern are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com