Stroboscopic lamp with wavy cooling fins

A technology of heat sink and strobe light, applied in the field of strobe light, can solve the problems of complicated parts manufacturing process, high logistics and storage cost, easy bumping and deformation, etc., to achieve performance and cost optimization, simple structure and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

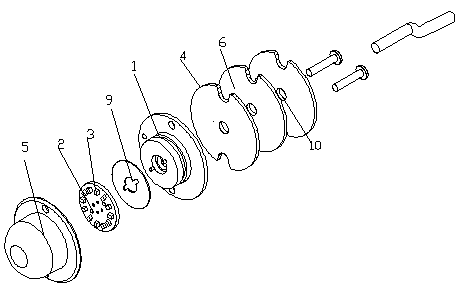

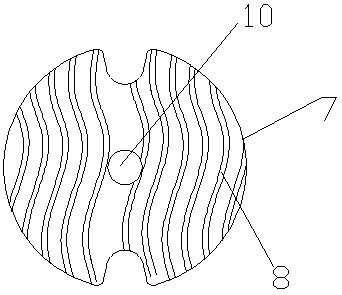

[0018] Such as Figure 1-2 As shown, this embodiment provides a strobe light with a wave-shaped heat sink, including a mounting base 1, a circuit board 2, an LED lamp bead 3, a heat dissipation assembly 4, and a mask 5. The LED lamp bead 3 passes through the circuit The board 2 is arranged at the upper end of the mounting base 1, the mask 5 is connected to the upper end of the mounting base 1, the heat dissipation assembly 4 is arranged at the lower end of the mounting base 1, and the heat dissipation assembly 4 is formed by splicing several heat sinks 6, so The heat sink 6 includes a main body 7, and a heat dissipation mechanism 8 is arranged on the end surface of the main body 7. The heat dissipation mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com