A kind of hot-rolled medium manganese trip steel containing trace zirconium and preparation method thereof

It is a technology of trace amount and excess amount, which is applied in the field of hot-rolled medium manganese TRIP steel and its preparation, which can solve the problems of limited application and popularization, increased cost, and deterioration of steel plate welding performance, and achieves the advantages of simple production process, simple composition and excellent welding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

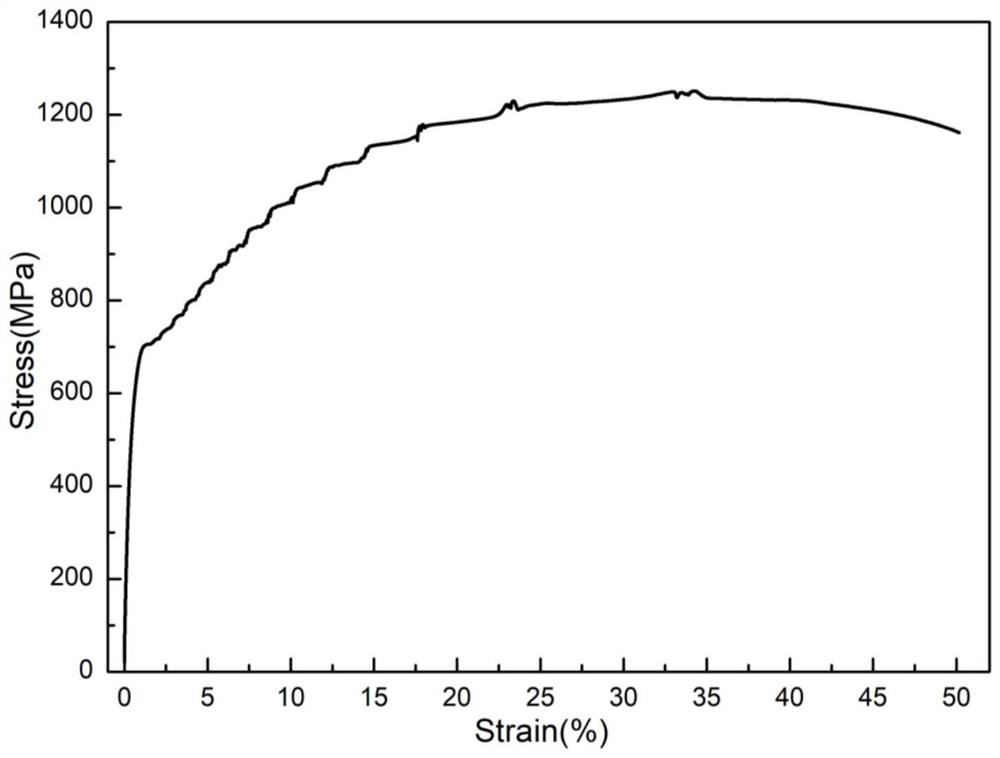

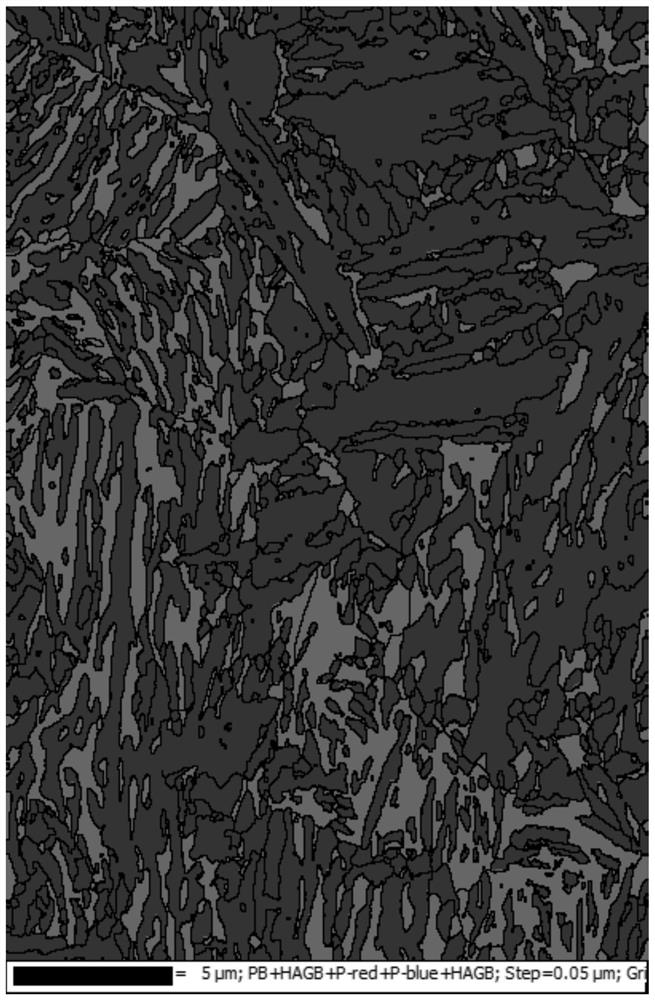

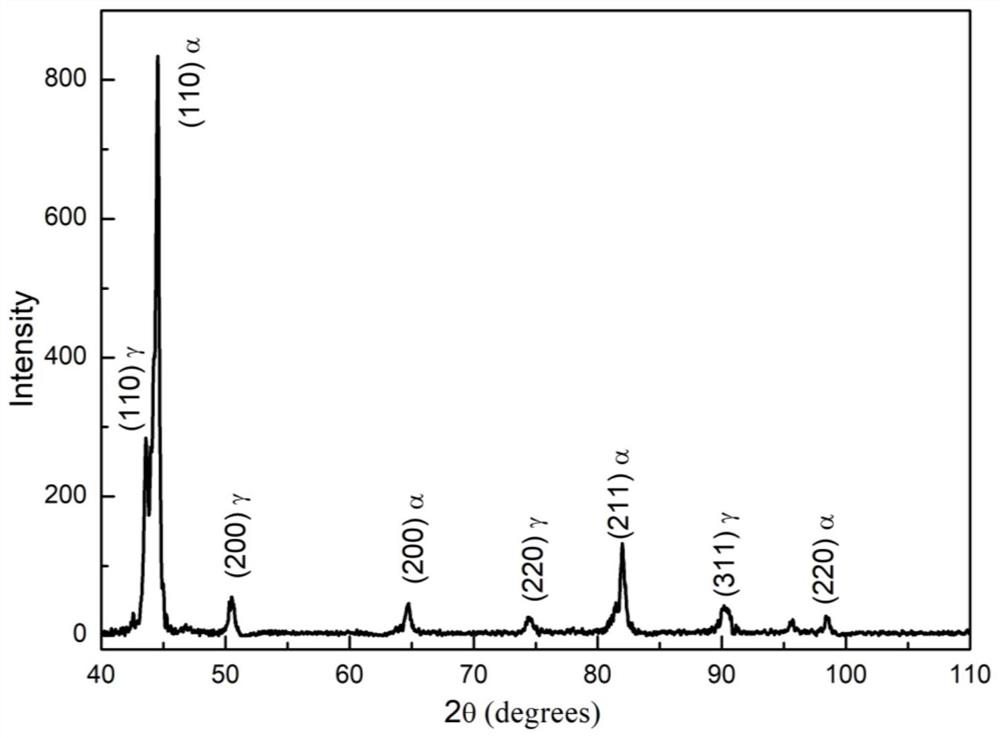

[0033] A hot-rolled medium-manganese TRIP steel containing trace zirconium, the chemical composition is: C: 0.18%, Mn: 7.89%, Al: 1.51%, Zr: 0.11%, P<0.008%, S<0.008% , the balance being Fe.

[0034] The preparation method of TRIP steel comprises the following steps:

[0035] Smelting and forging: According to the alloy composition, the steel ingot is vacuum smelted, the riser is removed and the scale is turned off. The steel ingot is forged after being held at 1200°C for 2 hours, the final forging temperature is not lower than 900°C, then air-cooled to room temperature, and finally forged into a slab sample with a thickness of 30mm.

[0036] Hot rolling: heat the forged billet at 1200°C for 2 hours, then conduct multi-pass rolling to a thickness of 4mm, and the final rolling temperature is not lower than 850°C.

[0037] Two-phase zone annealing: the hot-rolled steel sheet was annealed at 680°C for 1 hour and then air-cooled to room temperature.

[0038] Low-temperature tem...

Embodiment 2

[0040] A hot-rolled medium-manganese TRIP steel containing trace amounts of zirconium, the chemical composition of which is: C: 0.18%, Mn: 8.1%, Al: 1.47%, Zr: 0.08%, P<0.008%, S<0.008% , the balance being Fe.

[0041] The preparation method of TRIP steel comprises the following steps:

[0042] Smelting and forging: According to the alloy composition, the steel ingot is vacuum smelted, the riser is removed and the scale is turned off. The steel ingot is forged after being held at 1200°C for 2 hours, the final forging temperature is not lower than 900°C, then air-cooled to room temperature, and finally forged into a slab sample with a thickness of 30mm.

[0043] Hot rolling: heat the forged billet at 1200°C for 2 hours, then conduct multi-pass rolling to a thickness of 4mm, and the final rolling temperature is not lower than 850°C.

[0044] Two-phase zone annealing: the hot-rolled steel sheet was annealed at 660°C for 1 hour, and then air-cooled to room temperature.

[0045]...

Embodiment 3

[0047] A hot-rolled medium-manganese TRIP steel containing trace zirconium, the chemical composition is: C: 0.2%, Mn: 7.91%, Al: 1.51%, Zr: 0.06%, P<0.008%, S<0.008% , the balance being Fe.

[0048] The preparation method of TRIP steel comprises the following steps:

[0049]Smelting and forging: According to the alloy composition, the steel ingot is vacuum smelted, the riser is removed and the scale is turned off. The steel ingot is forged after being held at 1200°C for 2 hours, the final forging temperature is not lower than 900°C, then air-cooled to room temperature, and finally forged into a slab sample with a thickness of 30mm.

[0050] Hot rolling: heat the forged billet at 1200°C for 2 hours, and then perform multi-pass rolling to a thickness of 5mm, and the final rolling temperature is not lower than 850°C.

[0051] Two-phase zone annealing: the hot-rolled steel plate was annealed at 670°C for 1 hour and then air-cooled to room temperature.

[0052] Low-temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com