A method for preparing self-fluxing pellets of medium-low alkalinity chromium-containing all-vanadium-titanium

A low alkalinity and self-fluxing technology, which is applied in the field of iron and steel metallurgy and ironmaking, can solve the problems of high reduction pulverization rate, easy bursting rate, low compressive strength, etc. The effect of bonding into balls and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

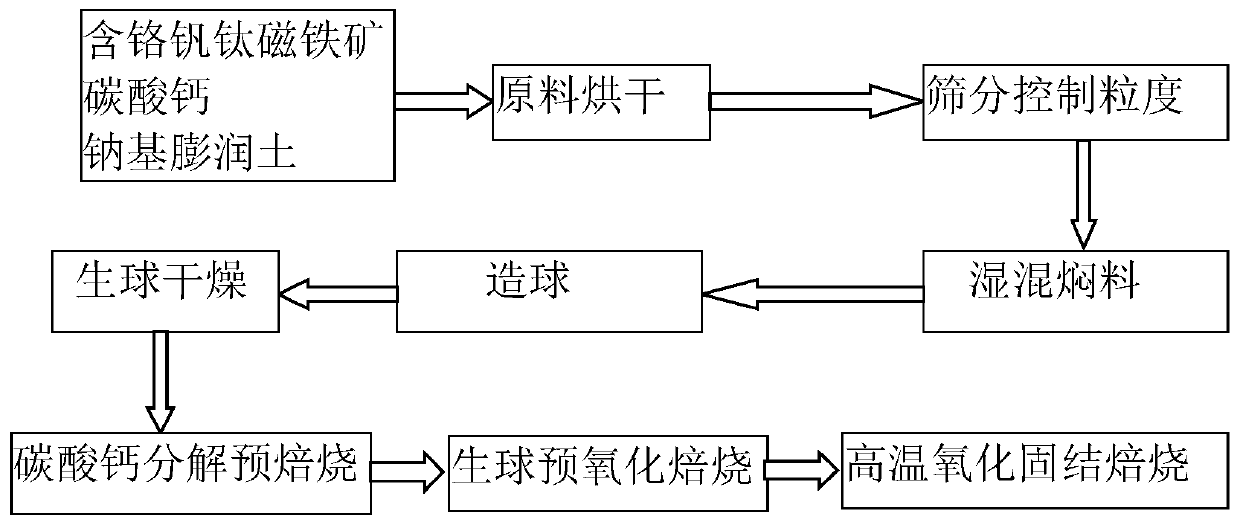

[0070] This embodiment provides a low-chromium vanadium-titanium magnetite in Hongge area as raw material ore, adding calcium carbonate and sodium bentonite to prepare a medium-low alkalinity low-chromium vanadium-titanium self-fluxing pellet The method, described method comprises following implementation steps:

[0071] (1) Raw material preparation: take 5Kg Hongge area low-chromium vanadium-titanium magnetite as raw material ore, prepare analytically pure calcium carbonate powder 230.19g, sodium-based bentonite 50g as additives, and prepare an alkalinity of 0.8-1.0.

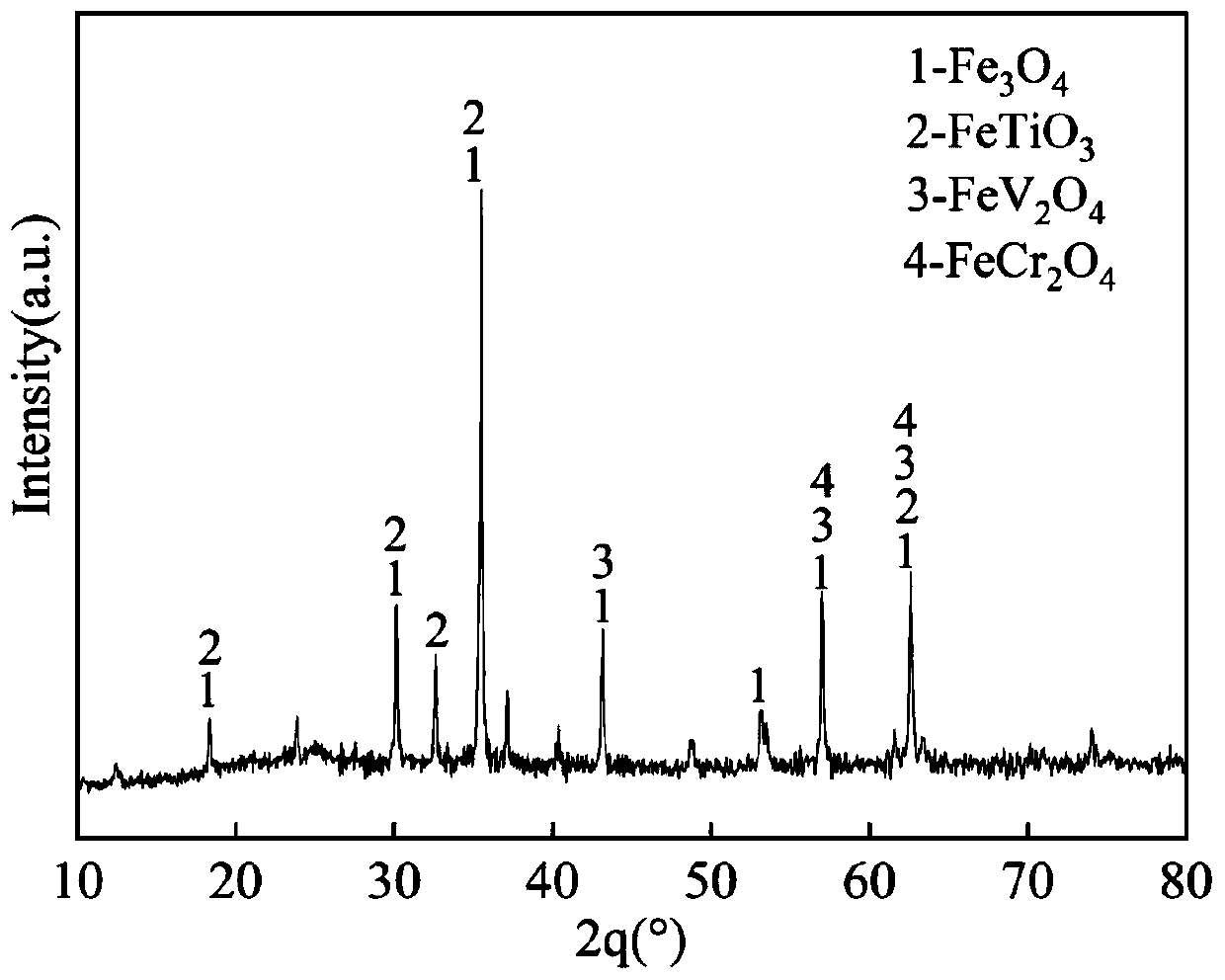

[0072] The X-ray diffraction pattern of the low-chromium vanadium-titanium magnetite in the Hongge area, such as figure 2 As shown, it contains the following composition and mass percentage: TiO 2 : 10wt%-12wt%, Cr 2 o 3 : 0.3wt%-0.6wt%, V 2 o 5 : 0.9wt%-1.4wt%, MgO: 2.5wt%-4wt%, CaO: 0.5wt%-1.0wt%, SiO 2 : 1wt%-3wt%; wherein, TFe is 53%-57wt%.

[0073] Taking 5Kg of raw material ore as a benchmark, res...

Embodiment 2

[0085] This embodiment provides a low-chromium vanadium-titanium magnetite in Hongge area as raw material ore, adding calcium carbonate and sodium bentonite to prepare a medium-low alkalinity low-chromium vanadium-titanium self-fluxing pellet The method, described method comprises following implementation steps:

[0086] (1) Raw material preparation: get 4Kg low-chromium type vanadium-titanium magnetite in Hongge area as raw material ore, prepare analytically pure calcium carbonate powder 183.34g, and sodium bentonite 40g as additives, and the alkalinity obtained is 0.9-1.1.

[0087] The X-ray diffraction pattern of the low-chromium vanadium-titanium magnetite in the Hongge area, such as figure 2 As shown, it contains the following composition and mass percentage: TiO 2 : 10wt%-12wt%, Cr 2 o 3 : 0.3wt%-0.6wt%, V 2 o 5 : 0.9wt%-1.4wt%, MgO: 2.5wt%-4wt%, CaO: 0.5wt%-1.0wt%, SiO 2 : 1wt%-3wt%; wherein, TFe is 53%-57wt%.

[0088] Taking 4Kg of raw material ore as a benchma...

Embodiment 3

[0100] This embodiment provides a low-chromium vanadium-titanium magnetite in Hongge area as raw material ore, adding calcium carbonate and sodium bentonite to prepare a medium-low alkalinity low-chromium vanadium-titanium self-fluxing pellet The method, described method comprises following implementation steps:

[0101] (1), raw material preparation: take 5Kg Hongge area low chromium type vanadium titanium magnetite as raw material ore, prepare analysis pure calcium carbonate powder 176.8g, sodium-based bentonite 50g as additives, prepare the mixture that alkalinity is 1.0-1.2 material.

[0102] The X-ray diffraction pattern of the low-chromium vanadium-titanium magnetite in the Hongge area, such as figure 2 As shown, it contains the following composition and mass percentage: TiO 2 : 10wt%-12wt%, Cr 2 o 3 : 0.3wt%-0.6wt%, V 2 o 5 : 0.9wt%-1.4wt%, MgO: 2.5wt%-4wt%, CaO: 0.5wt%-1.0wt%, SiO 2 : 1wt%-3wt%; wherein, TFe is 53%-57wt%.

[0103] Taking 5Kg of raw material or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com