Method for fermenting butanol by performing pretreatment on straw by adopting novel eutectic solvent

A deep eutectic solvent and butanol fermentation technology, applied in the field of bioengineering, can solve the problems of high cost, low glucose concentration, low hemicellulose removal rate, etc., and achieve the effect of less three wastes and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Novel deep eutectic solvent (ethylamine hydrochloride: lactic acid) pretreatment rice straw

[0027] Take 100g of ethylamine hydrochloride as the hydrogen bond acceptor and lactic acid as the hydrogen bond donor (see Table 1 for the molar ratio), add 10g of rice straw (the mass ratio of deep eutectic solvent to rice straw is 10:1), and heat at 140°C After stirring for 2 h, the mixture was centrifuged, and the precipitate was washed 3 times with deionized water. After drying to constant weight, sieve.

[0028] Add the treated straw to pH4.8, 50mM citric acid-sodium citrate buffer to form a mixed system, the final mass concentration of rice straw is 10% (w / v), add The cellulase was used for enzymolysis, and the enzymolysis was carried out at 50°C and 150rpm on a water bath shaker for 24h.

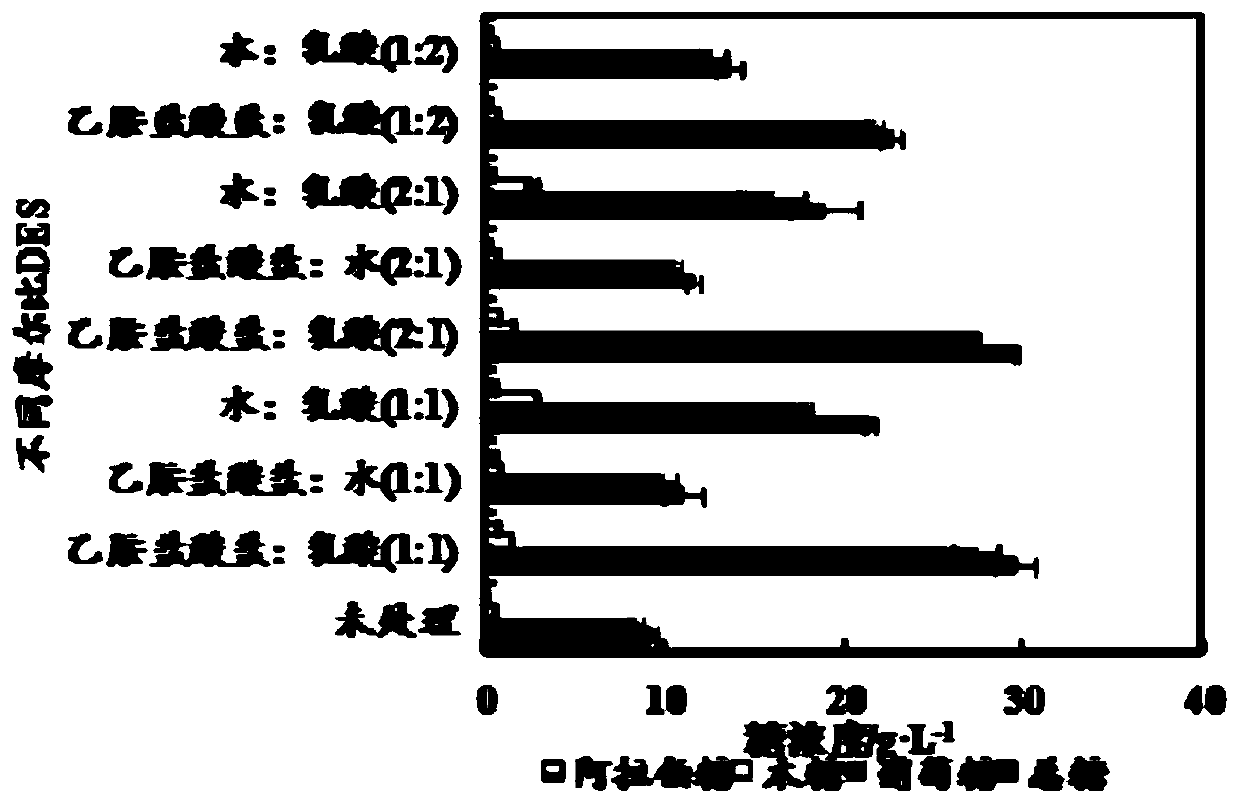

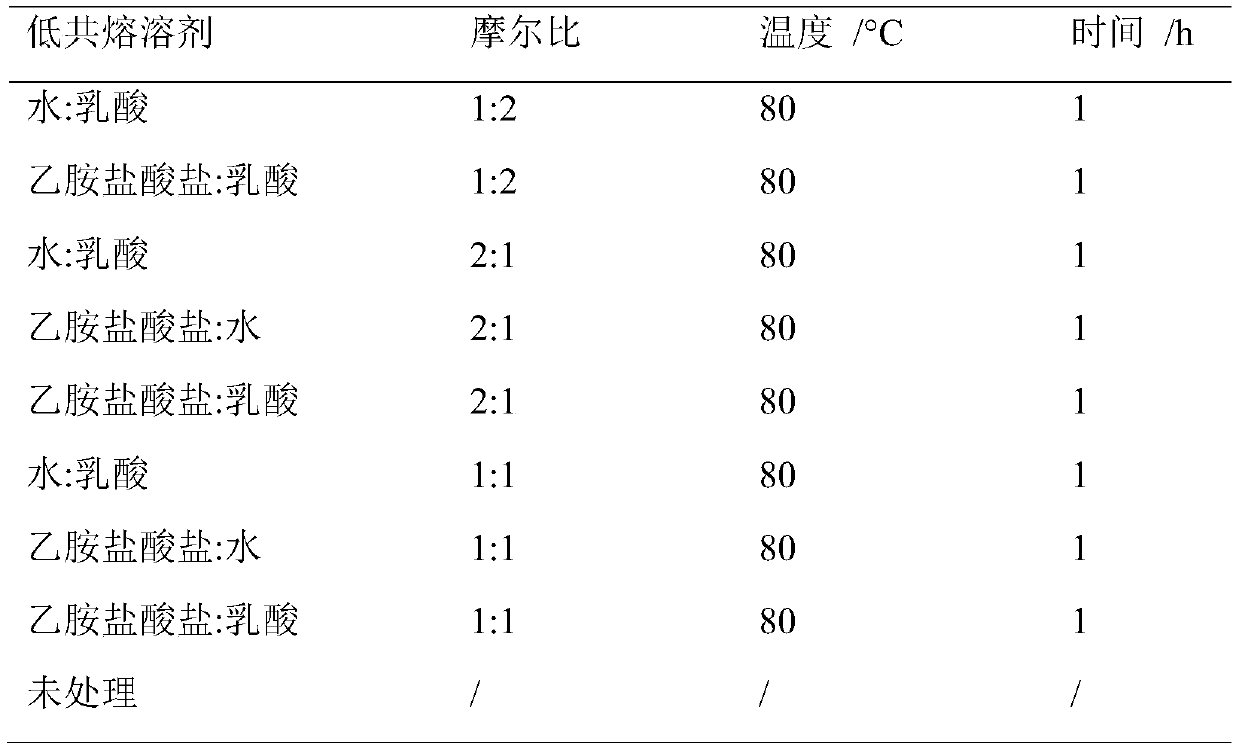

[0029] Table 1 Synthetic novel deep eutectic solvent method

[0030]

[0031] Simultaneously synthesize ionic liquids with different molar ratios of ethylamine hyd...

Embodiment 2

[0032] Embodiment 2: Novel deep eutectic solvent (ethylamine hydrochloride: lactic acid) combines sodium hypochlorite solution to pretreat rice straw

[0033] Take 100 g of ethylamine hydrochloride as the hydrogen bond acceptor and lactic acid as the hydrogen bond donor (see Table 1 for the molar ratio and synthesis method), add 10 g of rice straw (the mass ratio of deep eutectic solvent to rice straw is 10:1), The mixture was stirred at 140° C. for 2 h, then the mixture was centrifuged, and the precipitate was washed 3 times with deionized water. After drying to constant weight, sieve. Then soaking with 0.5% sodium hypochlorite for 6 hours, drying and sieving to obtain the rice straw combined with the deep eutectic solvent and sodium hypochlorite. Add the treated straw to pH4.8, 50mM citric acid-sodium citrate buffer to form a mixed system, the final mass concentration of rice straw is 10% (w / v), add The cellulase was used for enzymolysis, and the enzymolysis was performed...

Embodiment 3

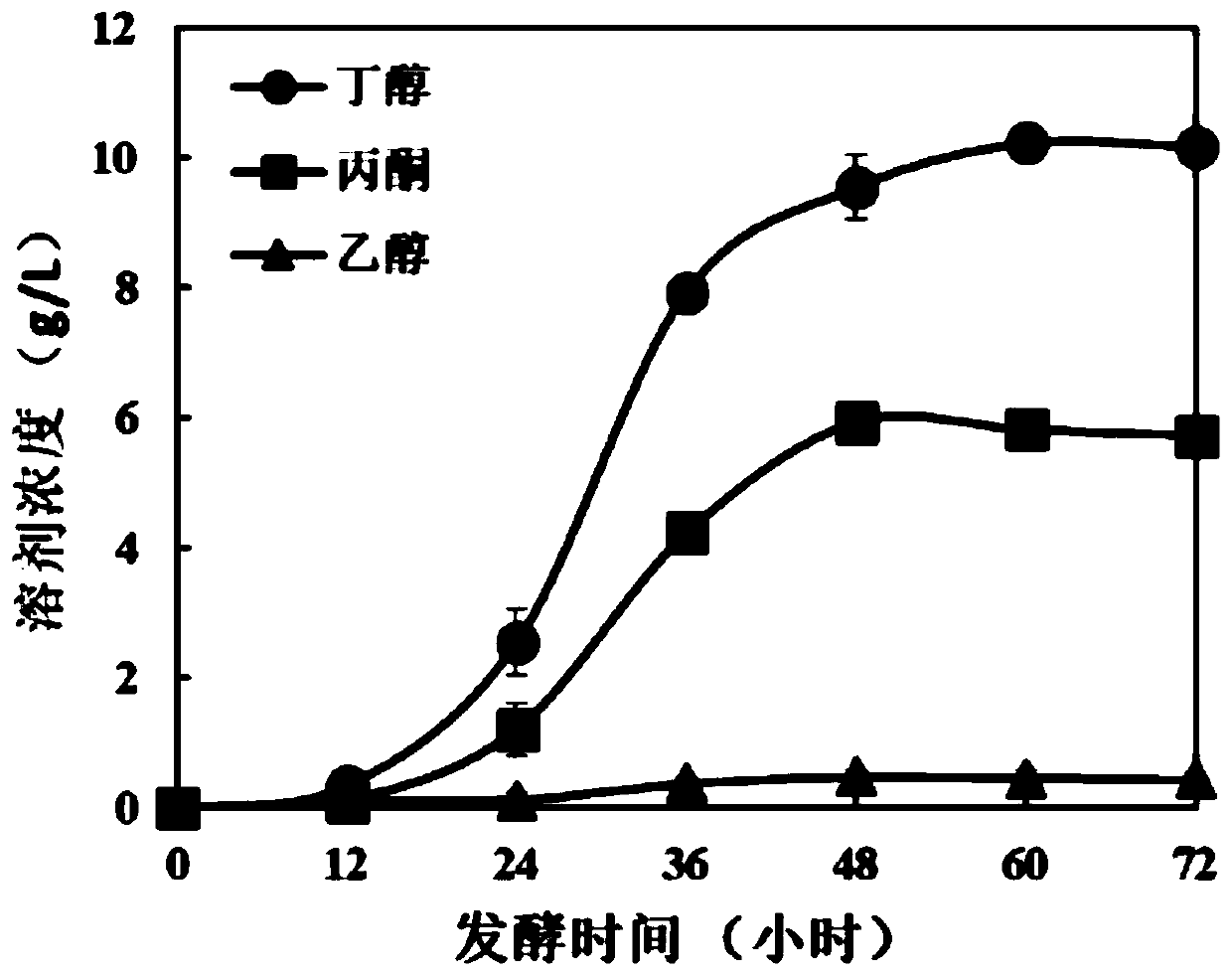

[0034] Example 3: Production of butanol by fermentation of pretreated rice straw hydrolyzate

[0035] Take a certain amount of combined pretreated rice straw, add pH 4.8, 50mM citric acid-sodium citrate buffer solution, and add The cellulase, so that the final solid-liquid ratio is 1:10, hydrolyzed on a water bath shaker at 50°C and 150rpm for 24h, centrifuged to obtain the rice straw hydrolyzate, and added the following ingredients to form a medium: corn steep liquor dry powder 10g L -1 , CaCO 3 4g·L-1 , (NH 4 ) 2 SO 4 2g·L -1 , K 2 HPO 4 0.5g·L -1 , MnSO 4 ·H 2 O 0.01g·L -1 . Adjust the pH to 6.5, and sterilize at 115°C for 20 minutes. Activated Clostridium saccharobutylicum DSM 13864 (10%, v / v) was inoculated and cultured anaerobically at 37°C. The result of fermentation and cultivation for 72h is as follows: figure 2 Shown, wherein, butanol production is 10.16g L -1 , the yield is The space-time yield is 0.14g·L -1 h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com