Low-viscosity normal-temperature-curable two-component epoxy glue and preparation method thereof

A room temperature curing, epoxy glue technology, applied in the direction of epoxy resin glue, adhesives, adhesive types, etc., can solve the problems of single style, low color and brightness of the appearance of the electroplating frame, etc., achieve a strong three-dimensional effect, improve the appearance and High-grade, high-gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

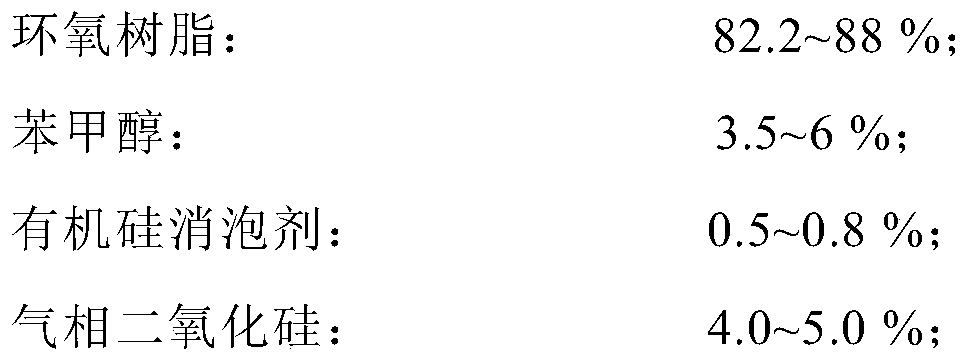

[0026] A kind of low-viscosity normal temperature curing two-component epoxy glue, it comprises epoxy material and curing material, described epoxy material (A component) comprises the following components by weight percentage:

[0027]

[0028] Described curing material (B component) comprises the following components by weight percentage:

[0029] Modified amine curing agent: 85%;

[0030] Epoxy resin: 5%;

[0031] Benzyl Alcohol: 10%.

[0032] Preparation method of epoxy glue:

[0033] ①Preparation of epoxy material (component A): According to the above formula, add epoxy resin into the reaction kettle, then add benzyl alcohol and silicone defoamer, mix and stir evenly, heat up to 85°C, and put it in a stirring state Add fumed silicon dioxide, stir to disperse evenly, add color paste and pearl powder after cooling, mix and stir evenly, and vacuumize for 15 minutes to obtain epoxy material.

[0034] ②Preparation of curing material (component B): Add the modified amine...

Embodiment 2

[0038] A kind of low-viscosity normal temperature curing two-component epoxy glue, it comprises epoxy material and curing material, described epoxy material (A component) comprises the following components by weight percentage:

[0039]

[0040] Described curing material (B component) comprises the following components by weight percentage:

[0041] Modified amine curing agent: 75%;

[0042] Epoxy resin: 10%;

[0043] Benzyl Alcohol: 15%.

[0044] Preparation method of epoxy glue:

[0045] ①Preparation of epoxy material (component A): According to the above formula, add epoxy resin into the reaction kettle, then add benzyl alcohol and silicone defoamer, mix and stir evenly, heat up to 70°C, and keep stirring Add fumed silicon dioxide, stir to disperse evenly, add color paste and pearl powder after cooling, mix and stir evenly, and vacuum for 8 minutes to obtain epoxy material.

[0046] ②Preparation of curing material (component B): Add the modified amine curing agent in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com