A photoinduced shape memory composite material capable of precise recovery and its preparation method

A light-induced shape memory and composite material technology, applied in the field of functional composite materials, can solve the problems of low deformation rate and low deformation recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

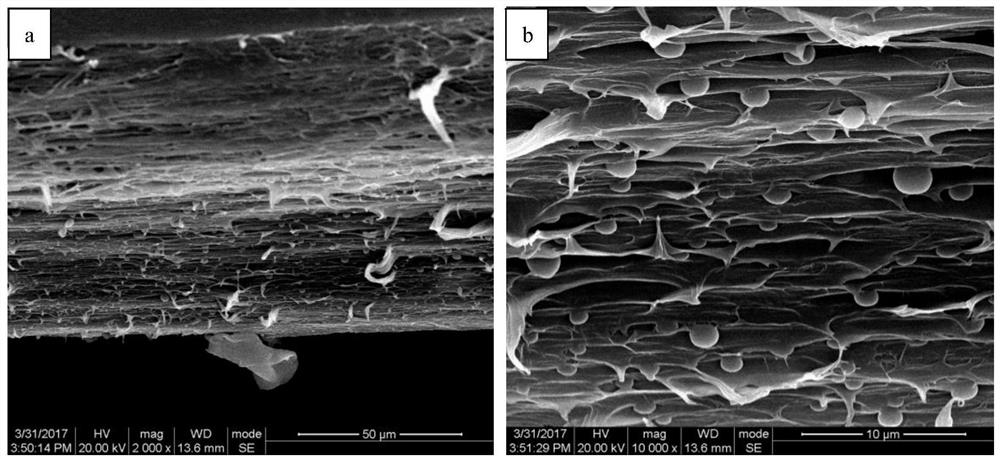

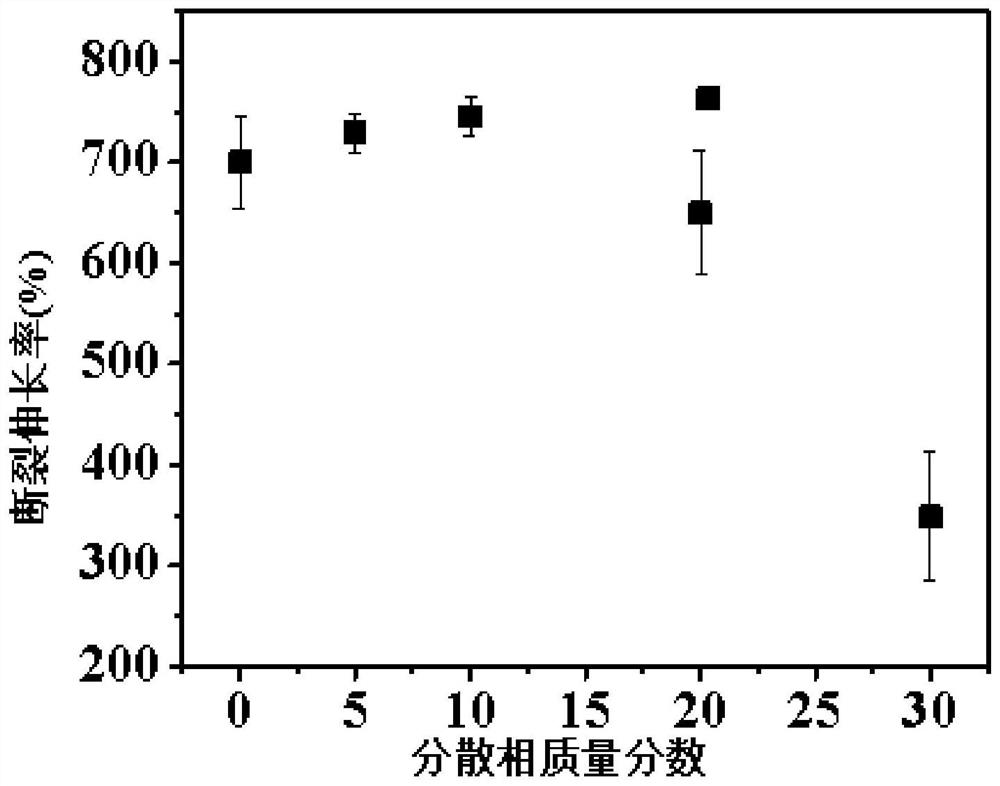

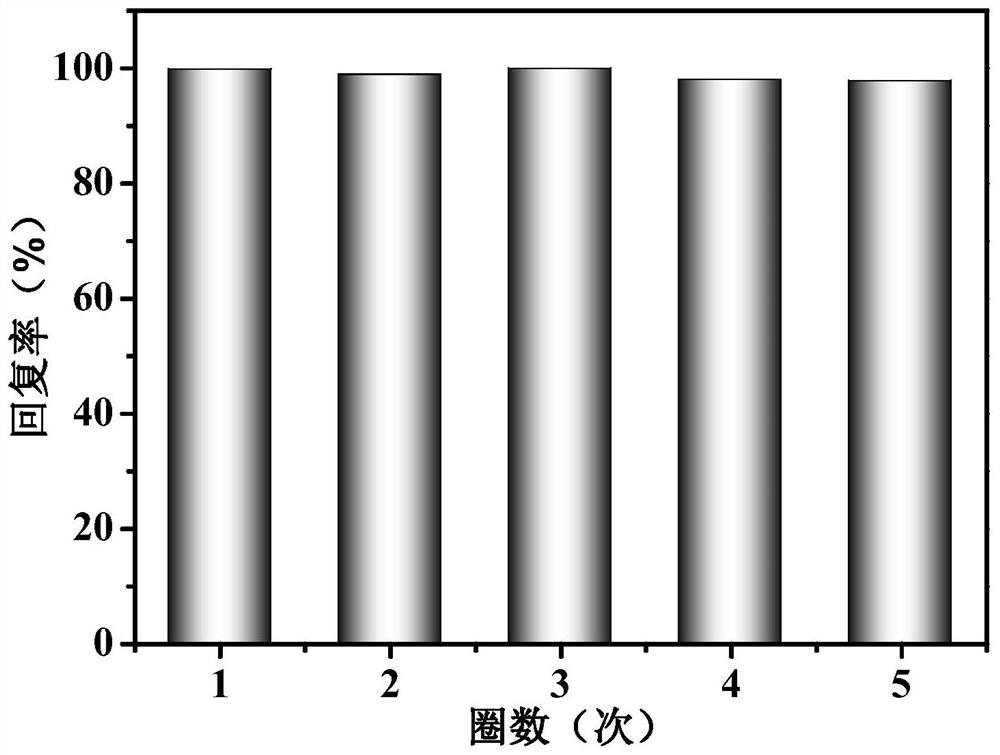

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of sulfonated carbon nanotubes (S-CNT): the suspension obtained after ultrasonication of carbon nanotube (0.25wt%) aqueous solution for 1h was added dropwise to the same volume of p-benzenesulfonic acid (0.46wt%) and super In the hydrochloric acid solution (0.15wt%) of potassium sulfate (0.18wt%), carry out sulfonation under the condition of ice-water bath for 4h, then wash with distilled water and dry;

[0042] (2) Preparation of PU / S-CNT solution: S-CNT DMF solution (0.15wt%) was ultrasonically dispersed for 1 h, then added to the same volume of PU DMF solution (15wt%) and mixed at 80°C for 15 minutes;

[0043] (3) Flocculation of PU / S-CNT composites: Pour the above solution into distilled water and keep stirring to obtain PU / S-CNT flocs, which are washed with distilled water and then dried;

[0044] (4) Preparation of HDPE / PU / S-CNT composite pellets: after crushing the dried PU / S-CNT composite, twin-screw extrusion and granulation with HDPE pellets to...

Embodiment 2

[0048] (1) Preparation of sulfonated carbon nanotubes: The suspension obtained after ultrasonication of carbon nanotube (0.25wt%) aqueous solution for 1h was added dropwise to the same volume containing p-benzenesulfonic acid (0.46wt%) and potassium persulfate (0.18wt%) %) in hydrochloric acid solution (0.15wt%), carry out sulfonation 4h under the condition of ice-water bath, then wash and dry with distilled water;

[0049] (2) Preparation of PU / S-CNT solution: ultrasonically disperse the DMF solution (0.15wt%) of S-CNT for 1 hour, then add it to the same volume of 80°C PU in DMF solution (15wt%) and mix for 15 minutes;

[0050] (3) Flocculation of PU / S-CNT composites: Pour the above solution into distilled water and keep stirring to obtain PU / S-CNT flocs, which are washed with distilled water and then dried;

[0051] (4) Preparation of HDPE / PU / S-CNT composite pellets: after crushing the dried PU / S-CNT composite, twin-screw extrusion and granulation with HDPE pellets to contro...

Embodiment 3

[0055] (1) Preparation of sulfonated carbon nanotubes: The suspension obtained after ultrasonication of carbon nanotube (0.25wt%) aqueous solution for 1h was added dropwise to the same volume containing p-benzenesulfonic acid (0.46wt%) and potassium persulfate (0.18wt%) %) in hydrochloric acid solution (0.15wt%), carry out sulfonation 4h under the condition of ice-water bath, then wash and dry with distilled water;

[0056] (2) Preparation of PU / S-CNT solution: ultrasonically disperse the DMF solution (0.15wt%) of S-CNT for 1 hour, then add it to the same volume of 80°C PU in DMF solution (15wt%) and mix for 15 minutes;

[0057] (3) Flocculation of PU / S-CNT composites: Pour the above solution into distilled water and keep stirring to obtain PU / S-CNT flocs, which are washed with distilled water and then dried;

[0058] (4) Preparation of HDPE / PU / S-CNT composite pellets: after crushing the dried PU / S-CNT composite, twin-screw extrusion and granulation with HDPE pellets to contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com