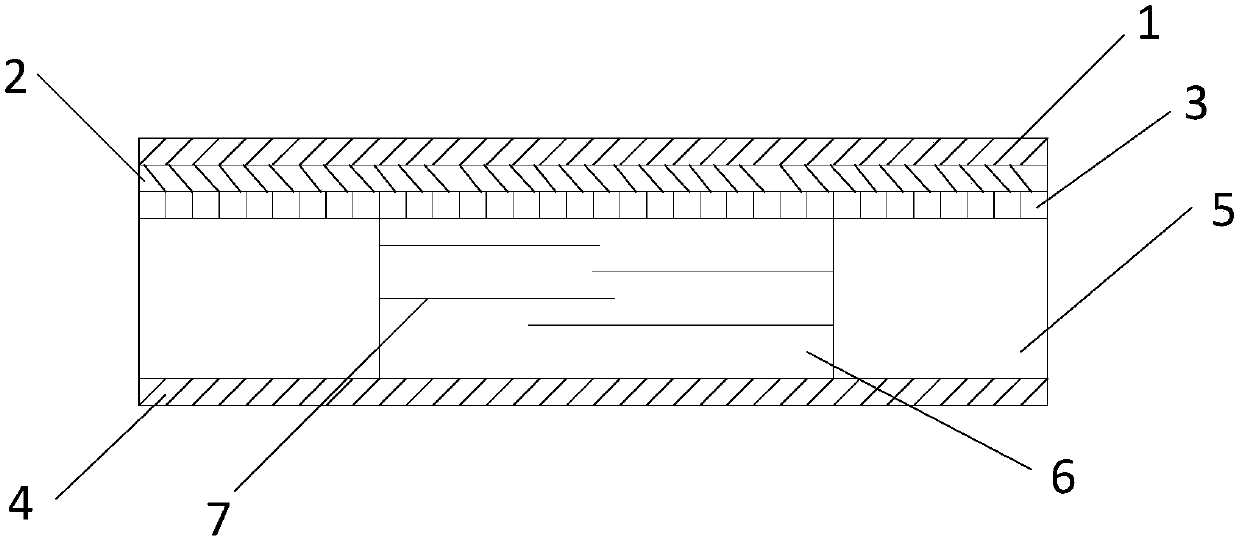

Sand-plastic partition wall with sound attenuation function

A partition wall and sand-plastic technology, applied to walls, building components, buildings, etc., can solve the problems of less research on purifying gas, achieve good noise reduction effect, improve overall uniformity, and avoid agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a method for preparing sand-plastic panels, including:

[0052] (1) Negative ion powder and deionized water are mixed according to the mass ratio of 1:10, and the temperature of the water bath is 40°C, and the water bath is ultrasonicated for 10 minutes to obtain the negative ion excitation material slurry;

[0053] (2) Select magnesium-aluminum spinel with a particle size of 2mm, spray aluminum sol on the surface of magnesium-aluminum spinel, so that aluminum sol is evenly coated on the outer surface of magnesium-aluminum spinel, and then spray negative ion excitation material slurry, Dry at 200°C to obtain negative ion generating materials;

[0054] In the negative ion generating material, the mass ratio of magnesium aluminum spinel to negative ion powder is 80:1; the consumption of described aluminum sol is 5% of magnesium aluminum spinel quality;

[0055] (2) Take by weighing 25Kg of quartz sand, 5Kg of negative ion generating material, 15K...

Embodiment 2

[0062] This embodiment provides a method for preparing sand-plastic panels, including:

[0063] (1) Negative ion powder and deionized water are mixed according to the mass ratio of 1:10, and the temperature of the water bath is 40°C, and the water bath is ultrasonicated for 10 minutes to obtain the negative ion excitation material slurry;

[0064] (2) Select magnesium-aluminum spinel with a particle size of 3mm, spray aluminum sol on the surface of magnesium-aluminum spinel, so that aluminum sol is evenly coated on the outer surface of magnesium-aluminum spinel, and then spray negative ion excitation material slurry, Dry at 250°C to obtain negative ion generating materials;

[0065] In the negative ion generating material, the mass ratio of magnesium aluminum spinel to negative ion powder is 80:4; the amount of aluminum sol is 5% of the mass of magnesium aluminum spinel;

[0066] (3) Weigh 35Kg of quartz sand, 7Kg of negative ion generating material, 20Kg of polypropylene res...

Embodiment 3

[0073] This embodiment provides a method for preparing sand-plastic panels, including:

[0074] (1) Mix nano-tourmaline and deionized water according to the mass ratio of 1:10, and at a water bath temperature of 40° C., ultrasonicate the water bath for 10 minutes to obtain a negative ion excitation material slurry;

[0075] (2) Select magnesium-aluminum spinel with a particle size of 5mm, and spray the aluminum sol on the surface of the magnesium-aluminum spinel in a sugar coating machine, so that the aluminum sol is evenly coated on the outer surface of the magnesium-aluminum spinel, and then spray Negative ion excitation material slurry is dried at 300°C to obtain negative ion generating material;

[0076] In the negative ion generating material, the mass ratio of magnesium-aluminum spinel to nano-tourmaline is 100:1; the amount of aluminum sol is 5% of the mass of magnesium-aluminum spinel;

[0077] (3) Weigh 30Kg of quartz sand, 6Kg of negative ion generating material, 19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com