A kind of preparation method of gelatin-stearic acid composite gel

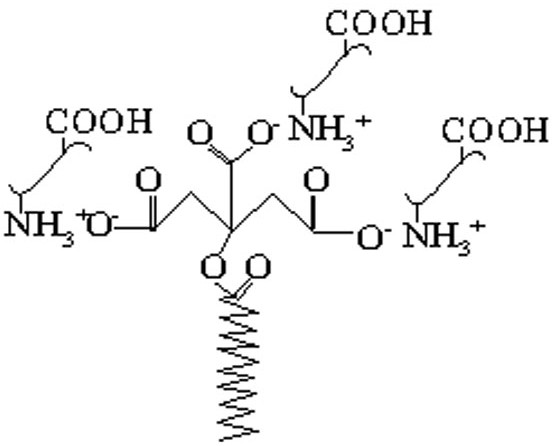

A composite gel and stearic acid technology, applied in the field of functional materials, to achieve the effect of uniform gel, strong practical value, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

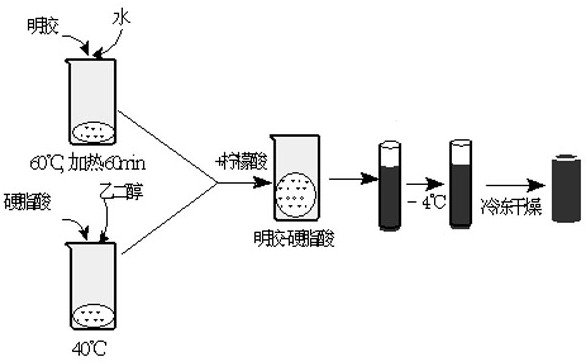

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 1g of gelatin in 9mL of water, heat at 60°C for 1h, and fully dissolve; then add 1mL of ethylene glycol to 0.02g of stearic acid, heat to dissolve, pour into the above gelatin solution, stir well to make it evenly mixed; Then add 1mL of citric acid solution with a mass fraction of 3%, continue to react for 1~4h, pour the reaction solution into a cylindrical mold, cool at room temperature to form a gel, and place it in a refrigerator (4°C) for 24h Fix the shape and freeze-dry for 48 hours to obtain a gelatin-stearic acid composite gel. The measured swelling rate is 95%, the compressive strength is 0.050MPa, and the fracture strain rate is 41.2%.

Embodiment 2

[0025] Weigh 1.5g of gelatin, dissolve in 10mL of water, heat at 60°C for 1h, and fully dissolve. Then add 1 mL of co-solvent ethylene glycol to 0.06 g of stearic acid, heat to dissolve, pour into the above gelatin solution, and mix well. Add 1mL of citric acid solution with a mass fraction of 4% to the mixture, continue to react for 1~4h, pour the reaction solution into a cylindrical mold, cool at room temperature to form a gel, and place it in a refrigerator (4°C). Place for 24 hours to fix the shape, and freeze-dry for 48 hours to obtain a gelatin-stearic acid composite gel. The measured swelling rate is 110%, the compressive strength is 0.246 MPa, and the fracture strain rate is 45.5%.

Embodiment 3

[0027] Weigh 2g of gelatin, dissolve in 10mL of water, heat at 60°C for 1h, and fully dissolve. Then add 2 mL of co-solvent ethylene glycol to 0.16 g of stearic acid, heat to dissolve, pour into the above gelatin solution, and mix well. In the mixture, add 1mL of citric acid solution with a mass fraction of 5%, continue to react for 1~4h, pour the reaction solution into a cylindrical mold, cool at room temperature to form a gel, and place it in a refrigerator (4°C) for 24h Fix the shape and freeze-dry for 48 hours to obtain a gelatin-stearic acid composite gel. The measured swelling rate is 162%, the compressive strength is 0.288MPa, and the fracture strain rate is 47.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com