Preparation and application of a dendrimer-modified reversed-phase/strong anion-exchange mixed-mode polymer

A technology of dendritic macromolecules and strong anions, which is applied to the materials of anion exchangers, anion exchange, ion exchange of chelates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

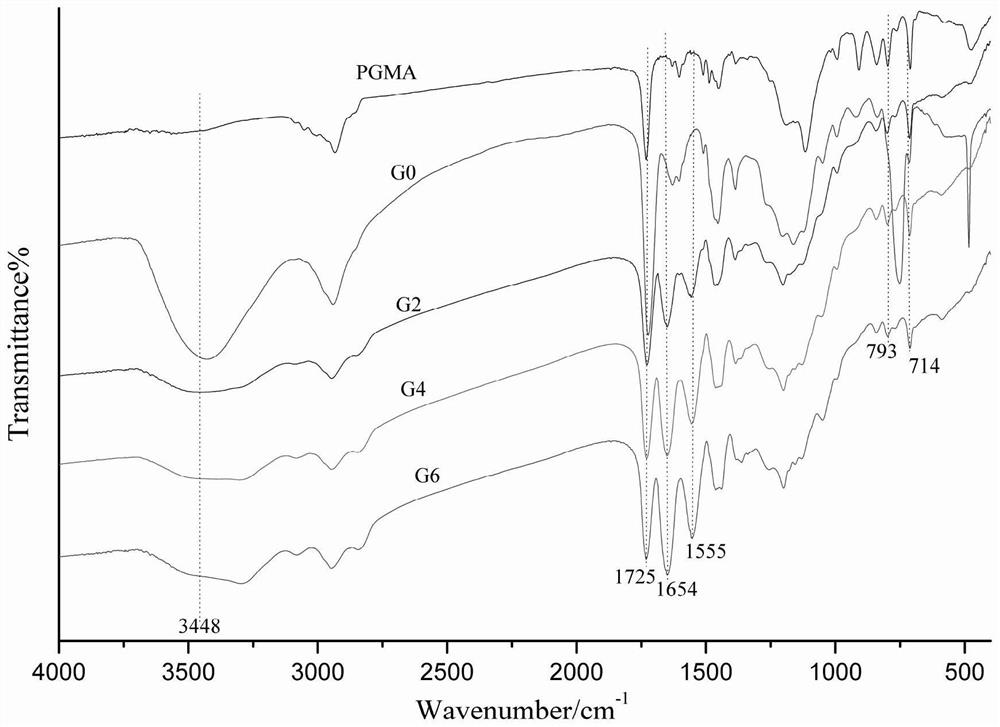

Method used

Image

Examples

Embodiment 1

[0035](1) Preparation of polymer microspheres

[0036]30 mmol (4.10 mL) of methacrylate (GMA), 20 mmol (2.85 mL) Diathylbenzene and 60 mg of azo diisobutyronitrile were dissolved in a porogen containing 6.87 g of toluene, and prepared a solution. A, the solution is placed in an ice bath, ultrasonic degassing 10 min, then the oxygen molecule is removed from the solution A. NANO-SIO with 80 mg particle size 12nm2Different to 10 ml of mass concentration of 0.02% Tritonx-100 aqueous solution, ultrasound 10min let Nano-SiO2Dispersed, then 3 ml of solution A was added, and then stirred with a homogenizer 6000 rpm / min, then the air was sealed from the air above the body 3 min, and the obtained Pickering emulsion was polymerized at 60 ° C for 24 h. After the reaction was completed, then 400 mesh and 230 mesh for stainless steel sieve, then use acetone to settle twice, 10 min each time, obtaining a particle size of 38-63 μm, polymer PGMA-SiO2. With methanol to extract the solvent, Sodhow extr...

Embodiment 2

[0038]30 mmol (4.10 mL) of methacrylate (GMA), 20 mmol (2.85 mL) Diathylbenzene and 60 mg of azo diisobutyronitrile (9 / 1, W) containing toluene / 1-diol (9 / 1, W) In a porogen solution of / W at (6.87 g), a solution A was prepared, and the solution was placed in an ice bath, ultrasonic degassed 10 min, and then the oxygen molecule was removed from the solution A. NANO-SIO with 80 mg particle size 12nm2Dissatis to 10 ml of mass concentration of 0.02% aqueous Tritonx-100 aqueous solution, ultrasound 5min let Nano-SiO2Dispersed, then 3 ml of solution A was added, and then stirred with a homogenizer 6000 rpm / min, then the air was sealed from the air above the body 3 min, and the obtained Pickering emulsion was polymerized at 60 ° C for 24 h. After the reaction was completed, then 400 mesh and 230 mesh for stainless steel sieve, then use acetone to settle twice, 10 min each time, obtaining a particle size of 38-63 μm, polymer PGMA-SiO2. With methanol to extract the solvent, Sodhow extra...

Embodiment 3

[0040]30 mmol (4.10 mL) of methacrylate (GMA), 20 mmol (2.85 mL) divinylbenzene and 60 mg of azo diisobutyronitrile (7 / 3, W) containing toluene / 1-tertiacol (7 / 3, W) In a porogen solution of / W at (6.87 g), a solution A was prepared, and the solution was placed in an ice bath, ultrasonic degassed 10 min, and then the oxygen molecule was removed from the solution A. NANO-SIO with 80 mg particle size 12nm2Dissatis to 10 ml of mass concentration of 0.02% aqueous Tritonx-100 aqueous solution, ultrasound 5min let Nano-SiO2Dispersed, then 3 ml of solution A was added, and then stirred with a homogenizer 6000 rpm / min, then the air was sealed from the air above the body 3 min, and the obtained Pickering emulsion was polymerized at 60 ° C for 24 h. After the reaction was completed, then 400 mesh and 230 mesh for stainless steel sieve, then use acetone to settle twice, 10 min each time, obtaining a particle size of 38-63 μm, polymer PGMA-SiO2. With methanol to extract the solvent, Sodhow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com