Hank reel

A winch and rack technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of reducing production efficiency, affecting production efficiency, long axial length, etc., to improve production efficiency, The effect of realizing the automation of threading and reducing the load of the rotating shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

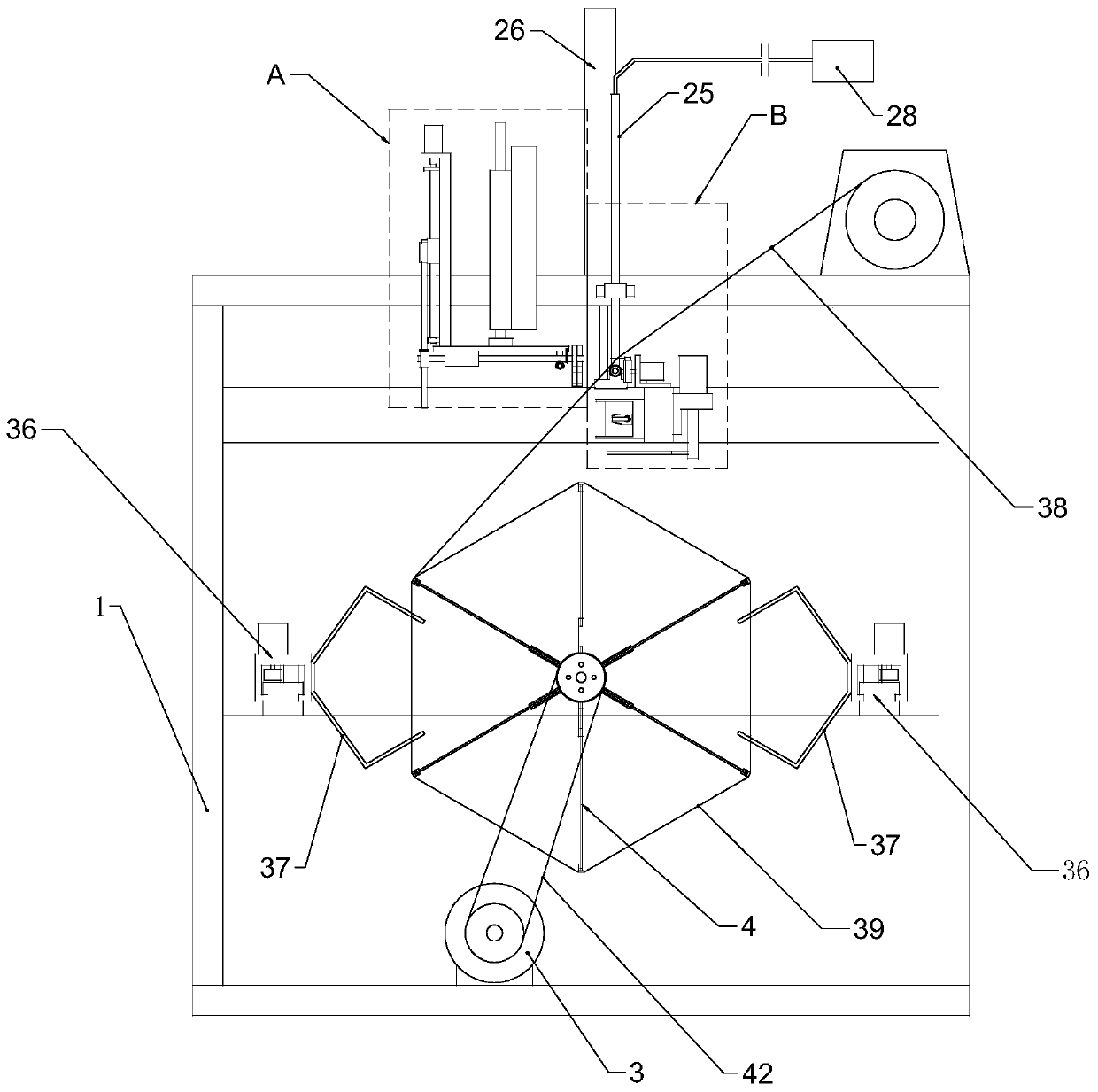

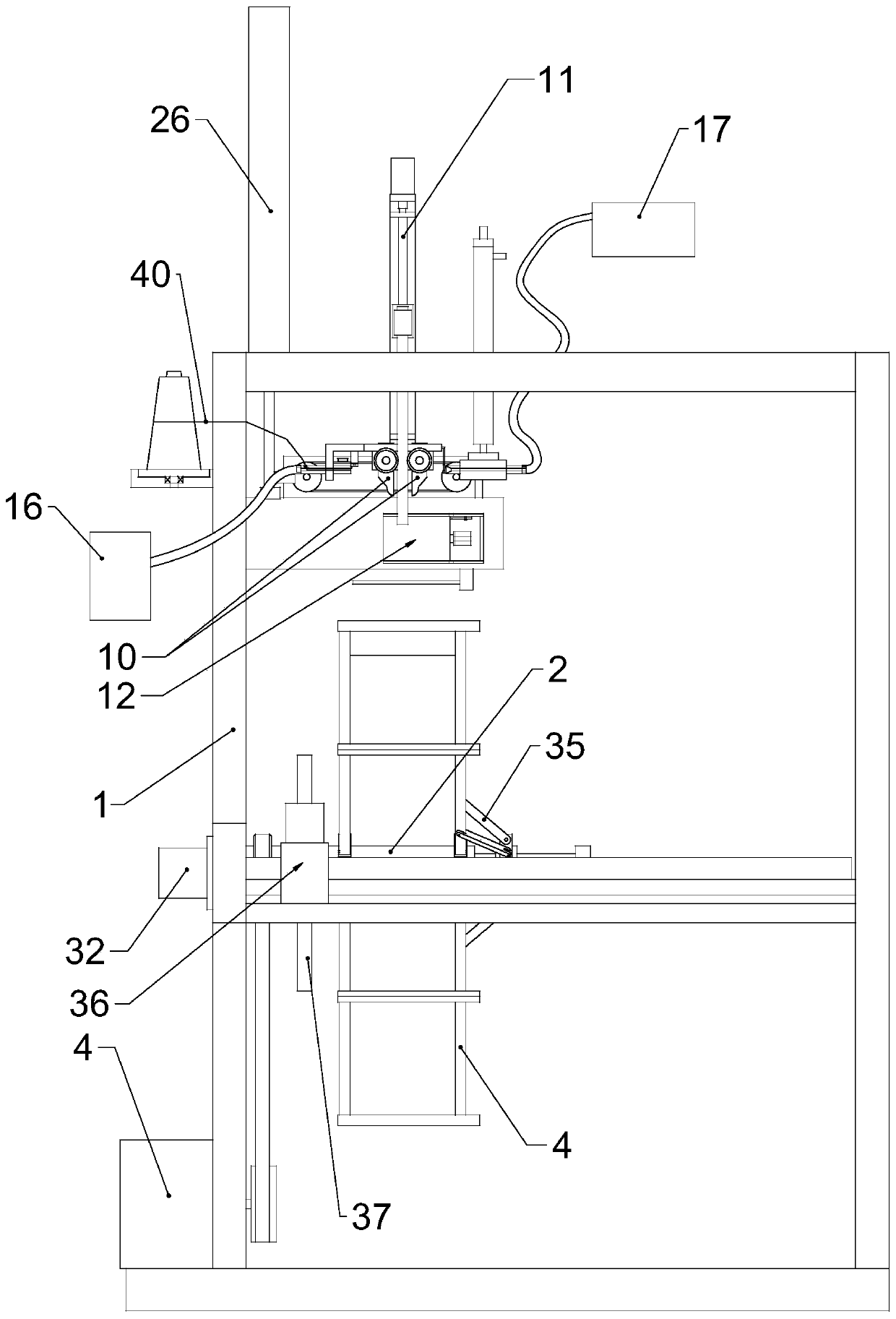

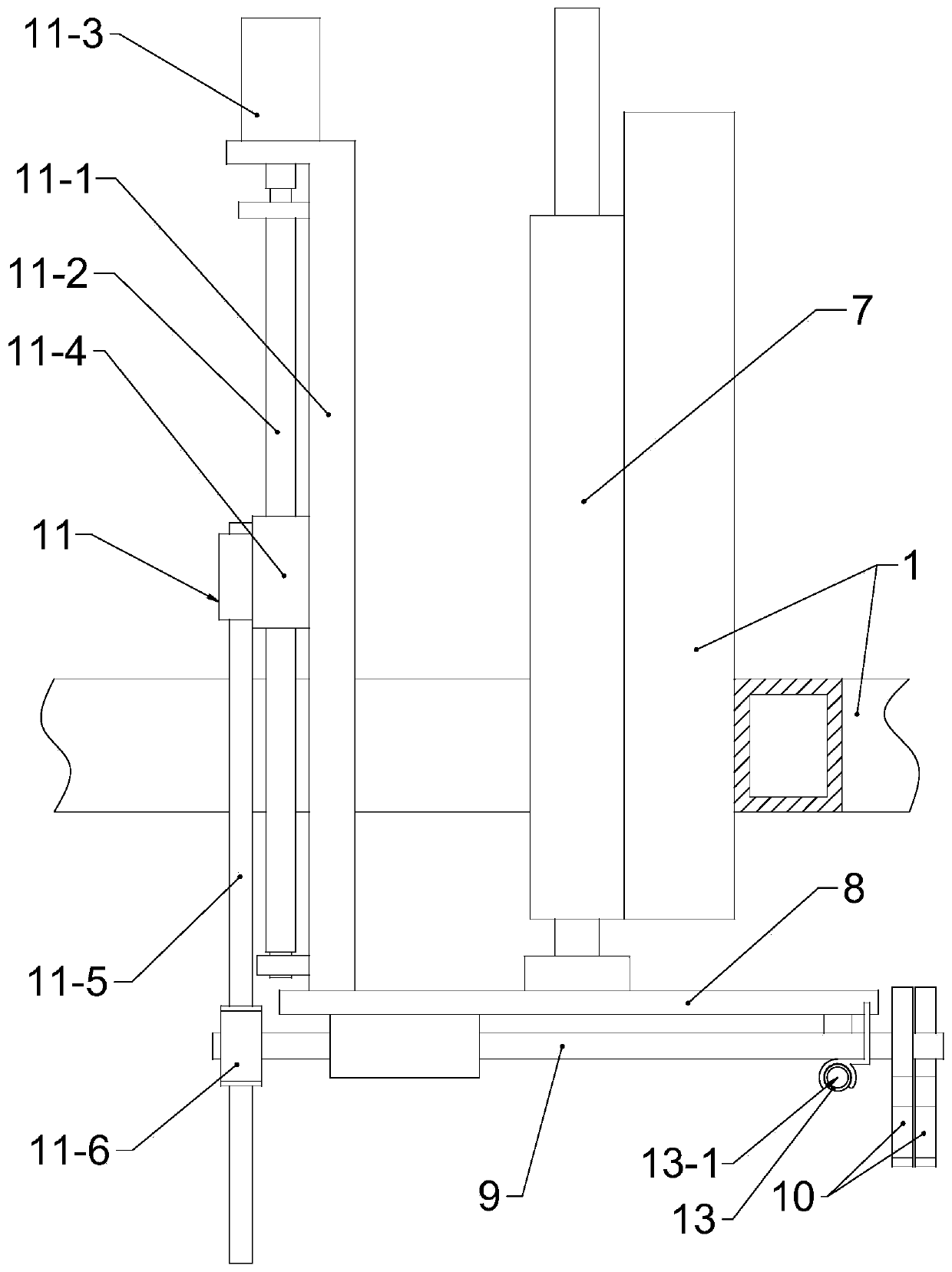

[0049] like figure 1 and figure 2 As shown, the winching machine includes a frame 1, on which a horizontally arranged rotating shaft 2 and a main driving device 3 for driving the rotating shaft 2 are rotatably connected, and a rotary yarn frame 4 is fixedly connected on the rotating shaft 2, One end of the rotating shaft 2 is connected with the frame 1, and the other end is suspended, such as figure 1 and Figure 7 As shown, a yarn guide ring 5 is movably connected to the frame 1 above the rotary yarn frame 4, and the yarn guide ring 5 can move back and forth along the axial direction parallel to the rotating shaft 2. The frame 1 is also provided with a The yarn guide driving device 6 that the ring 5 moves back and forth.

[0050] combine Figure 10 As shown, the main driving device 3 is a servo motor or a stepping motor, which drives the rotating shaft 2 to rotate through the belt 42 , and the rotating shaft 2 is provided with a driven wheel 43 which is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com