Multi-angle adjustment edge grinding machine for grinding surface of alloy material

An alloy material, multi-angle technology, which is applied to machine tools, grinders, grinding workpiece supports, etc. suitable for grinding workpiece edges, can solve the problem of weak edge adjustment function, inconvenient adjustment of alloy material positions, and inconvenient multi-angle positions. adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

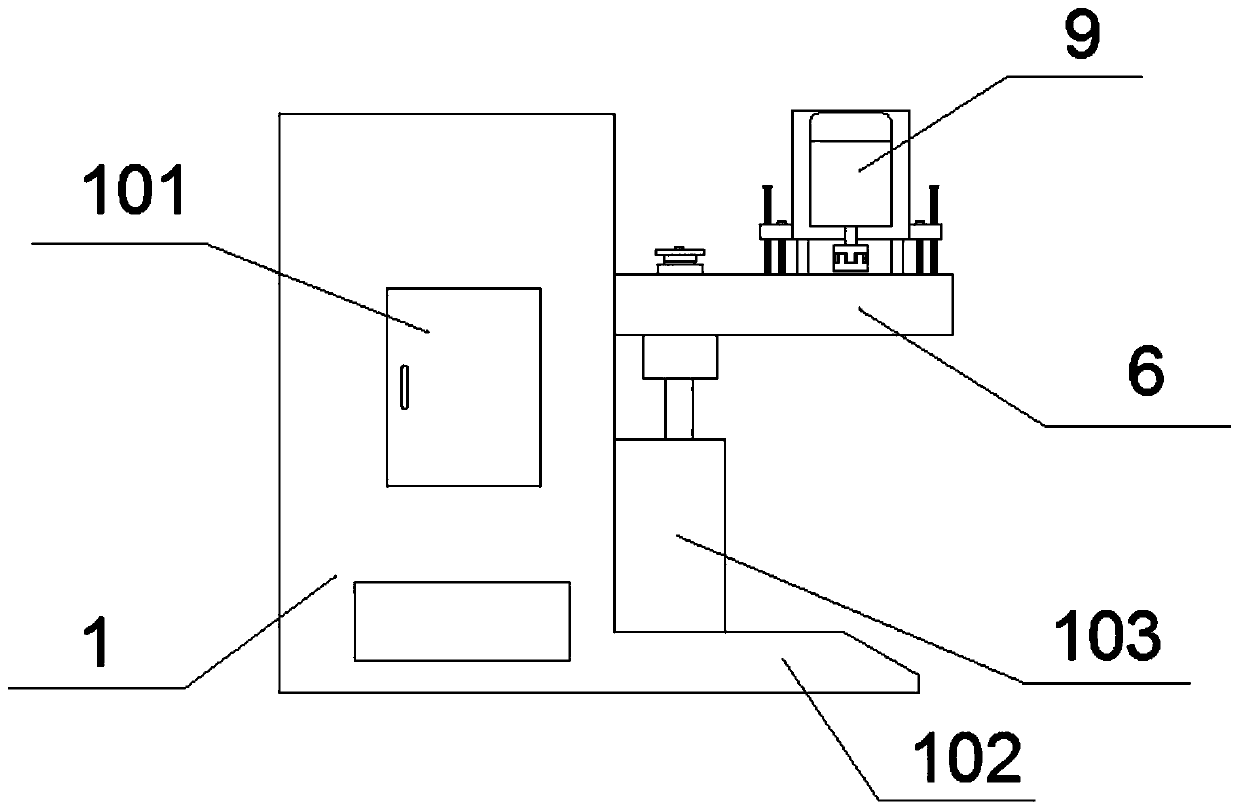

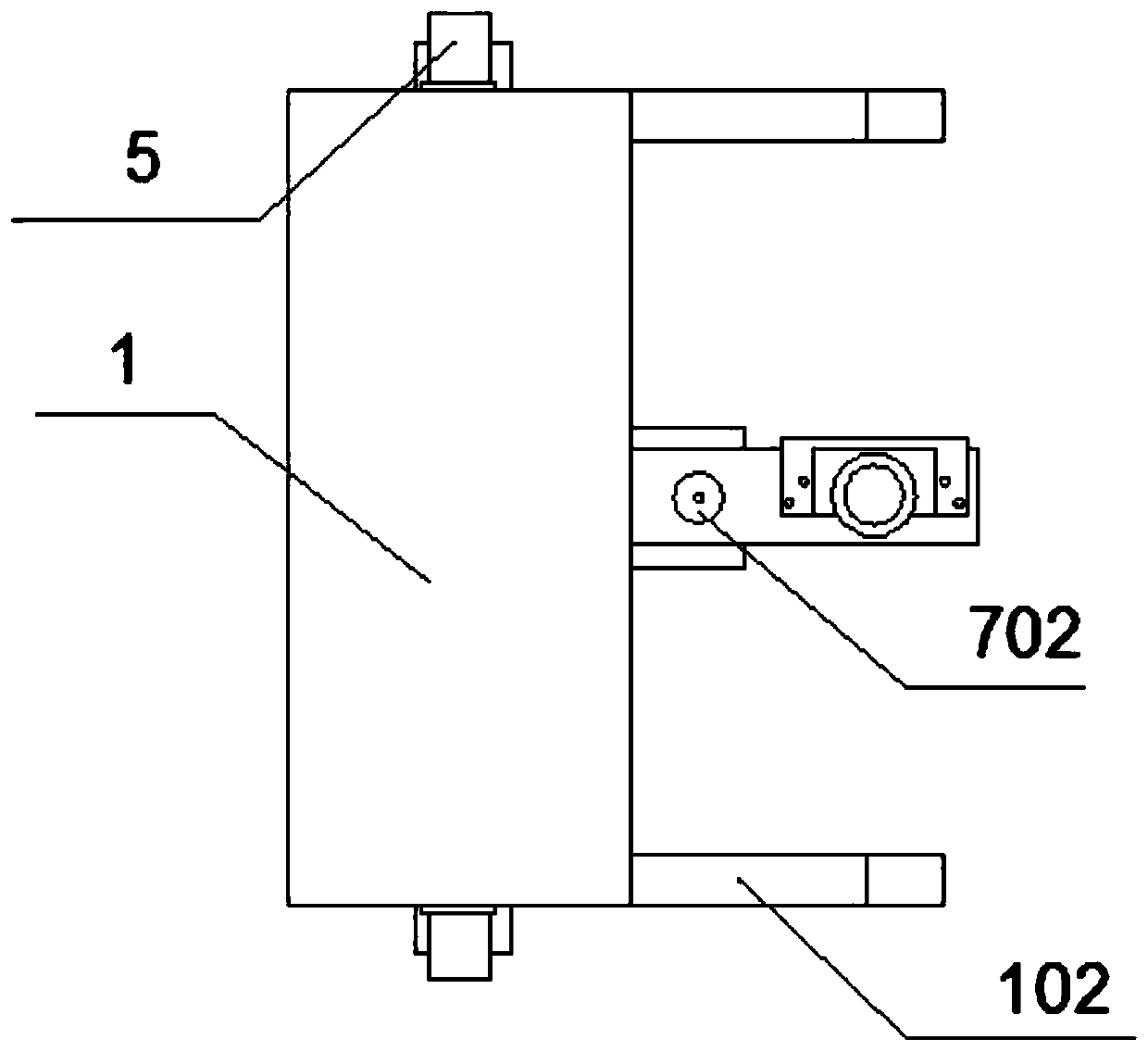

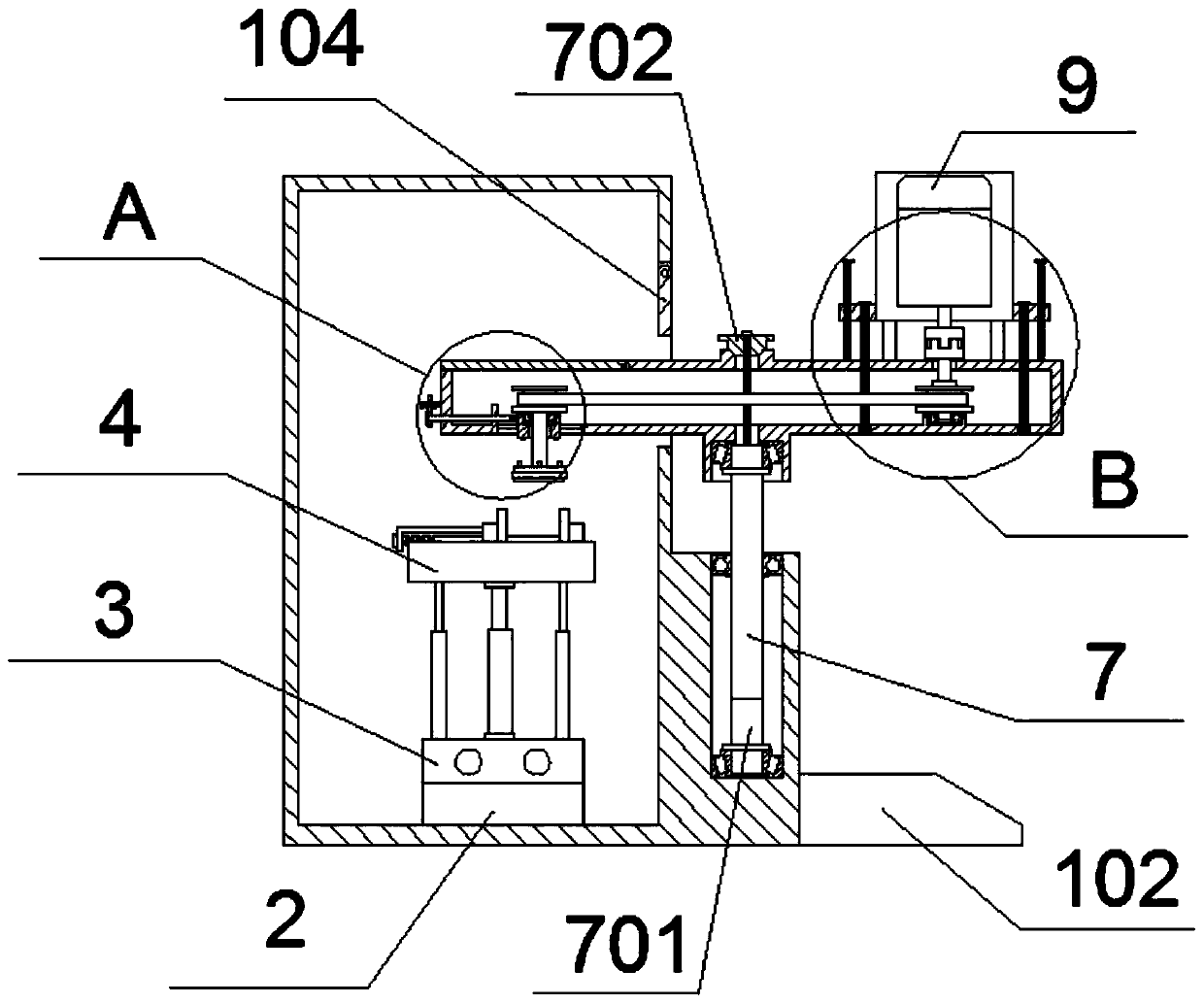

[0033] As attached figure 1 Attached Figure 8 Shown:

[0034] The present invention provides a multi-angle adjustment edging machine for surface polishing of alloy materials, which includes a housing 1, a side door 101, an auxiliary foot plate 102, a connecting tube 103, an inner shutter 104, a guide rail 2, a sliding table 3, a tooling table 4, and a fixed Clamping block 401, movable clamping block 402, control rod 403, moving motor 5, grinding device 6, pulley A601, pulley B602, balance bar 7, bottom rod head 701, top locking block 702, motor plate 8, side plate 801, Polishing motor 9, guide rod 901, movable wheel frame 10, polishing tool 11, pulling tool 12 and tensioning plate 13; a side door 101 is opened in the middle of one side of the housing 1, and a cleaning port is opened at the bottom of the side door 101; The bottom and both ends of the shell 1 side are integrally extended with auxiliary foot boards 102; the bottom of the shell 1 is integrally provided with a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com