An Intelligent Judgment and Disposal Method for Continuous Casting Outage Accidents

A disposal method and a technology of intelligent judgment, applied in the field of steel continuous casting, can solve problems such as accident expansion, and achieve the effect of improving the level of automation and improving the labor efficiency of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

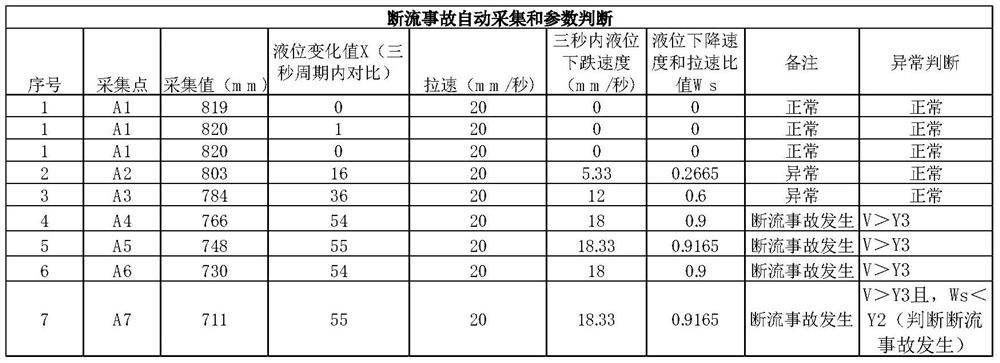

[0027] In this example, the state of the casting machine has five working modes: "preparation", "uploading", "holding", "pouring", and "tail blank", of which the "pouring" mode is the normal working mode;

[0028] The liquid level height control mode has three control modes: "automatic", "manual" and "semi-automatic", of which the "automatic" mode is the normal control mode;

[0029] The allowable minimum pulling speed value set by the process is 0.6m / min;

[0030] The height range of molten steel in the normal working mold is 860mm to 720mm;

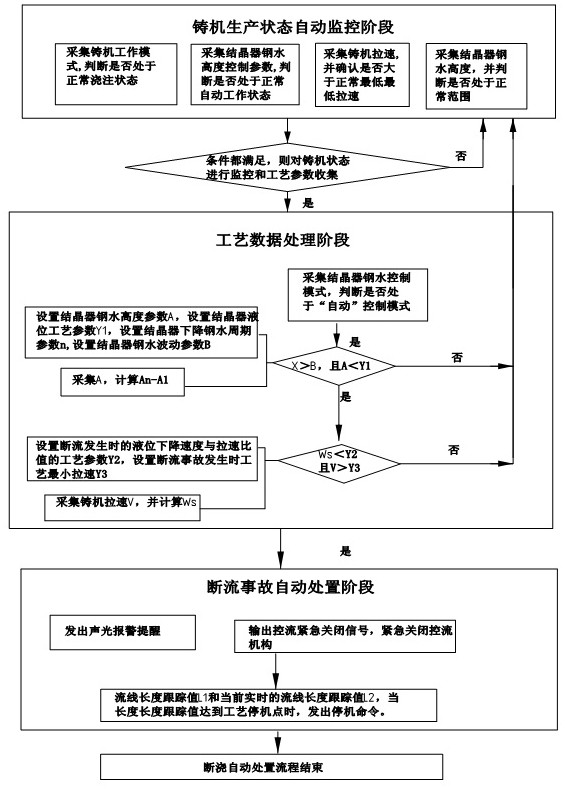

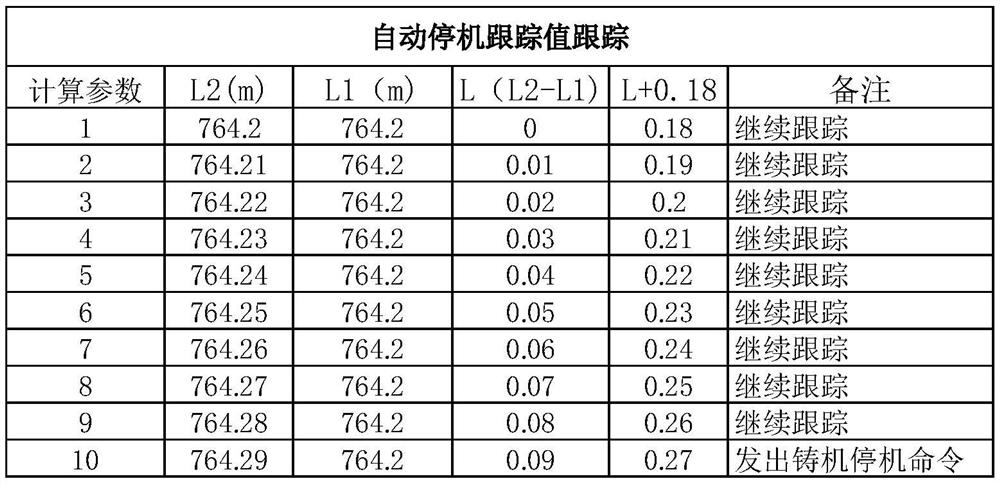

[0031] A method for intelligently judging and disposing of a flow interruption accident in continuous casting includes three parts: automatic monitoring of the production state of a casting machine in the first stage, process data processing in the second stage, and automatic disposal of the flow interruption accident in the third stage. It is characterized in that, the method comprises the following steps:

[0032] 1. Automatic monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com