Ultraviolet irradiation device for cable curing

An external irradiation and cable technology, applied in the field of light curing, can solve the problems of low utilization efficiency of light irradiation, uneven curing, high working power, etc., to improve the use efficiency and irradiation uniformity, ensure product quality stability, improve The effect of production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

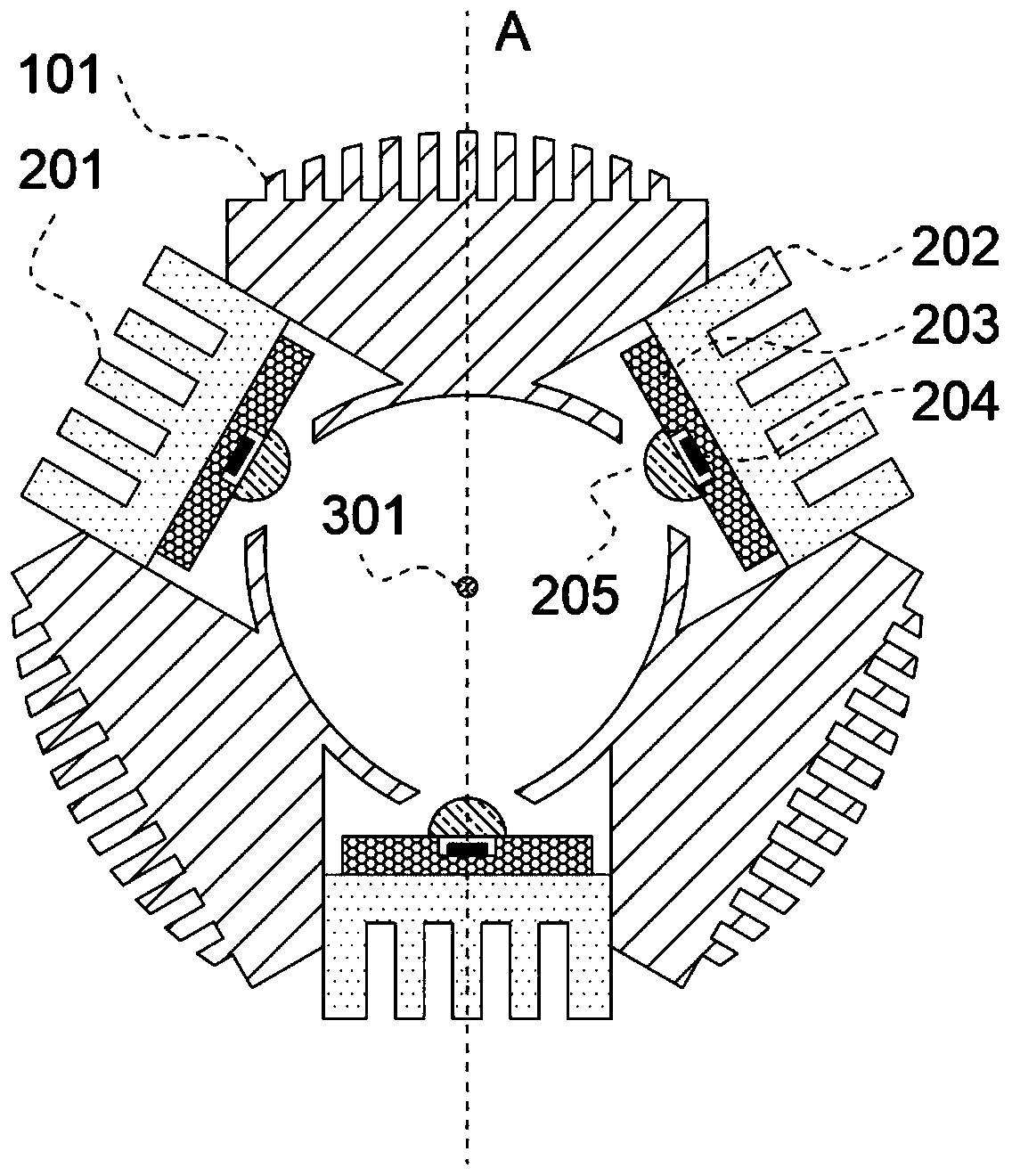

[0047] see figure 1 and figure 2 , figure 1 It is an assembly structure diagram of the ultraviolet irradiation device used for cable curing in this embodiment, figure 2 for along figure 1 The cross-sectional view of the A-axis in the middle, while figure 1 also along figure 2 Sectional view of the middle B axis. An ultraviolet irradiation device for cable curing includes 3 reflector modules 101 and 3 UV LED light source modules 201, the reflector modules 101 and UV LED light source modules 201 are alternately arranged to form a structure with an opening in the middle (i.e. the aforementioned Opening area, the same below), the object to be irradiated 301 is located in the center of the opening structure.

[0048] Wherein, the material of the reflector module 101 is aluminum alloy, and its side facing away from the middle opening structure is a fin structure that facilitates heat dissipation, and its surface facing the opening structure side is a polished arc surface, a...

Embodiment 2

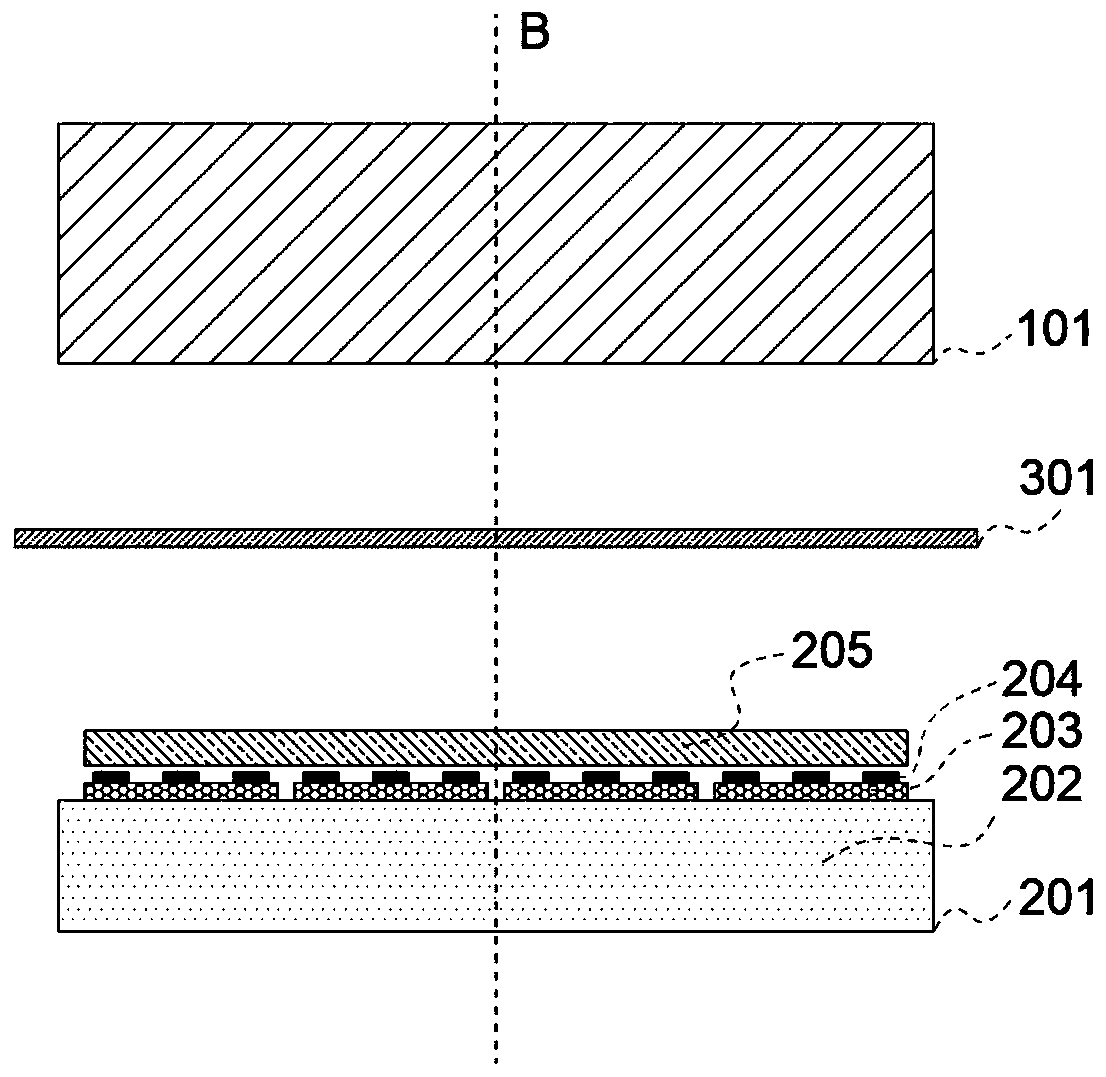

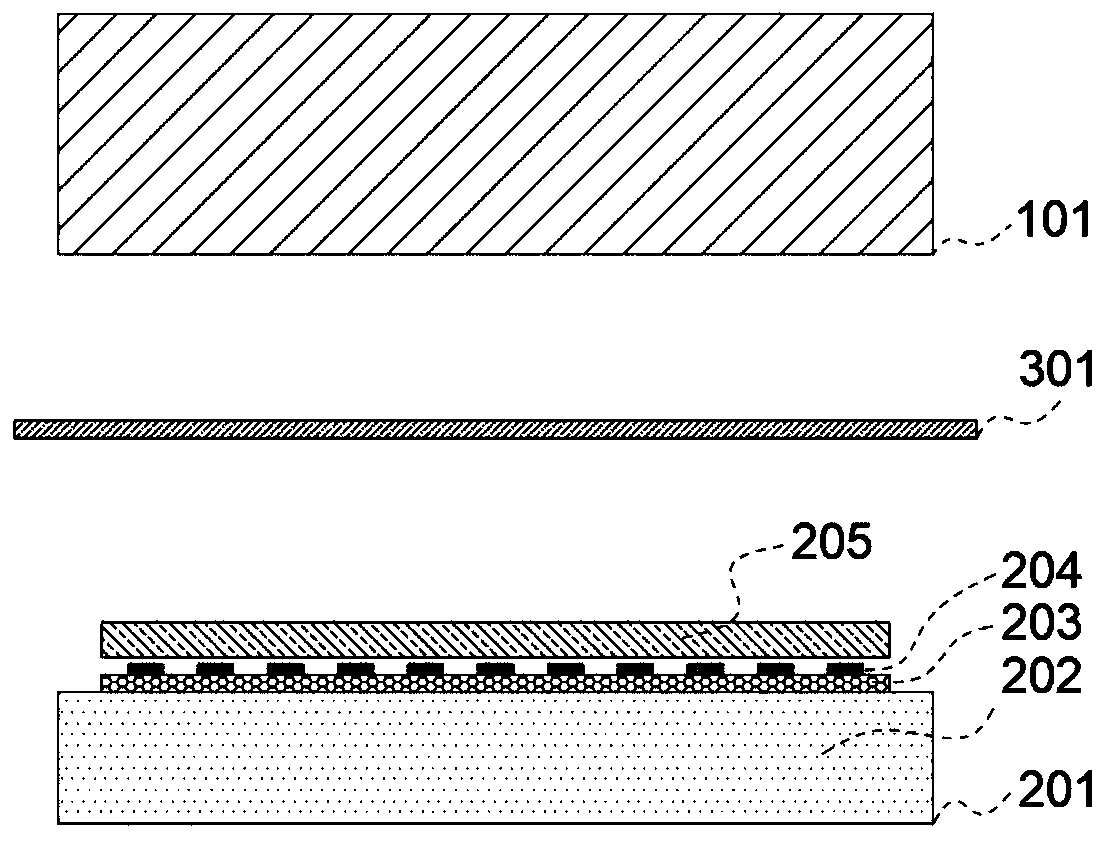

[0052] like image 3 As shown, an ultraviolet irradiation device for cable curing, its main structure is the same as that of embodiment 1, the difference is that in this embodiment, in order to improve the integration of products and the ease of installation, each UV LED light source module 201 Only one substrate 203 is included, and eleven chips 204 will be mounted on the same substrate 203 to form a COB-shaped UV LED lamp bead, and each UV LED light source module 201 contains only one COB-shaped UV LED lamp bead.

Embodiment 3

[0054] see Figure 4 and Figure 5 , this embodiment discloses another embodiment of the ultraviolet irradiation device, Figure 4 It is the assembly structure drawing of this embodiment, Figure 5 for along Figure 4 The cross-sectional view of the A-axis in the middle, while Figure 4 also along Figure 5 Sectional view of the middle B axis.

[0055] Specifically, an ultraviolet irradiation device for cable curing includes three reflector modules 111 and three UV LED light source modules 211, and the reflector modules 111 and UV LED light source modules 211 are alternately arranged to form a structure with an opening in the middle The ring device, the object 301 to be irradiated is located in the center of the opening structure.

[0056] Wherein, the reflector module 111 is made of stainless steel, and its side facing away from the opening structure is a fin structure that is good for heat dissipation, and its side facing the opening structure is a long groove shape, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com