Tail gas treatment equipment and method used for high-temperature drying and cleaning of oil-contained steel scrap

A high-temperature drying and tail gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as a large amount of smoke and environmental protection difficulties, and achieve the effect of improving the reliability of system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

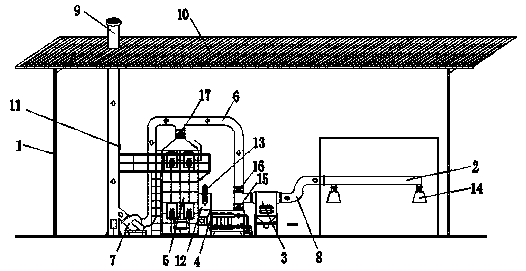

[0022] see figure 1 , the present invention provides a technical solution: an exhaust gas treatment equipment for high-temperature drying and cleaning of oily scrap steel, including a frame 1, an exhaust gas pipe 2, a sedimentation dust collector 3, a cooler 4, a high-voltage electrostatic purification device 5, and a bypass flue 6. The induced draft fan 7 and the exhaust cylinder 8, the exhaust gas pipe 2, the settling dust collector 3, the cooler 4, the high-voltage electrostatic purification equipment 5, the bypass flue 6 and the induced draft fan 7 are all arranged on the frame 1 The inside of the exhaust gas pipe 2 is provided with a connecting air pipe 8, and the two ends of the connecting air pipe 8 are respectively connected with the exhaust gas pipe 2 and the settling dust collector 3, and the cooler 4 is arranged on the outside of the settling dust collector 3, the high-voltage electrostatic purification equipment 5 is arranged on the outside of the cooler 4, and the...

Embodiment approach

[0025] As a preferred embodiment of the present invention, the outside of the high-voltage electrostatic purification equipment 5 is provided with a connection block 12, and the inside of the connection block 12 is provided with a high-voltage terminal 13, and the connection block 12 and the high-voltage electrostatic purification device The device 5 is fixed by means of rivets.

[0026] As a preferred embodiment of the present invention, the lower part of the exhaust gas pipe 2 is provided with an air collecting hood 14 , and the gas collecting hood 14 is fixed below both ends of the exhaust gas pipe 2 .

[0027] As a preferred embodiment of the present invention, the connection between the bypass flue 6 and the cooler 4 is provided with a first electric valve 15, and the upper part of the first electric valve 15 is provided with a second electric valve 16 , the connection between the high-voltage electrostatic purification equipment 5 and the bypass flue 6 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com