Method for judging and processing fissure development zone of goaf

A processing method and a technique for developing areas, which are applied in the field of judgment and processing of fissure developing areas in goafs, can solve the problems of strong subjective experience, poor quantification and accuracy, and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

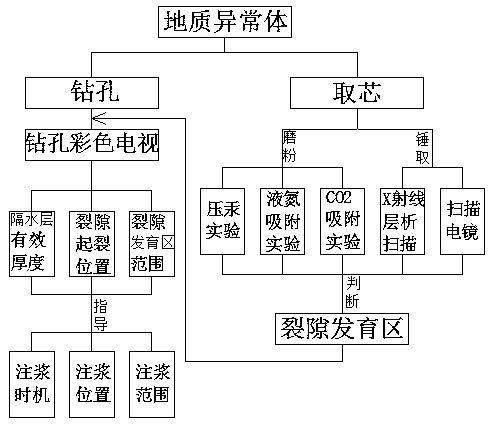

[0029] Such as figure 1 As shown, a method for prediction of fracture development area in goaf and advanced grouting includes the following steps:

[0030] S01: The surrounding rock in the goaf of a coal mine has undergone large deformation and slight damage. Drill holes in the unstable body area of the surrounding rock to take cores. The diameter φ of the drill holes is 60mm. It is the area with the most developed pores on the coal rock mass, and the length is 550mm.

[0031] S02: Part of the coal rock sample obtained from the drill hole is crushed into small pieces by a crusher, and then ground into powder by a ball mill, wherein the total mass of the powder is 100g, and the particle size is less than 100 mesh.

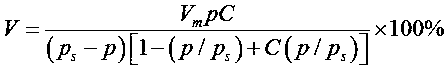

[0032] S03: First take 10g of coal and rock powder ground in S02, dry it in an oven at 70°C to 80°C for 12 hours, then take about 4g of dried coal and rock sample powder for mercury intrusion experiment to measure the macropores (aperture diameter) in the coal an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com