A method for improving the safety of ignition paper preparation

A safety, asbestos paper technology, applied in textiles and papermaking, can solve the problems of high energy consumption, low production efficiency, and energy consumption of ignition paper, and achieve improved production and operation safety, improved work safety, and reduced contact. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

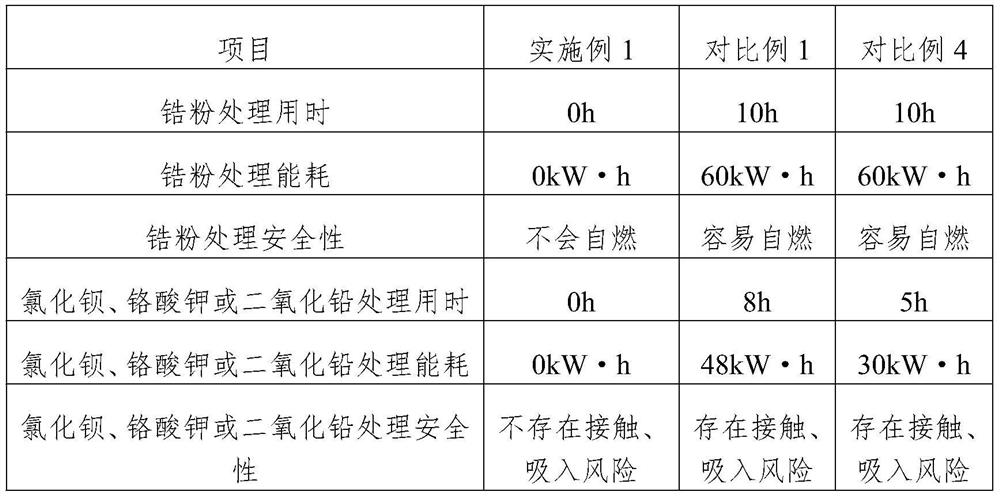

Examples

Embodiment 1

[0039] A method for improving the safety of ignition paper preparation, comprising the following steps:

[0040] (1) use moisture tester to measure the water content of zirconium powder, barium chloride and potassium chromate, according to the difference of water content of zirconium powder, barium chloride and potassium chromate, calculate the dry weight of raw material respectively by formula, and chlorine Barium chloride and potassium chromate are dissolved in distilled water respectively, obtain barium chloride solution and potassium chromate solution; Described formula is: W 1 (1-N%)=W 2 or W 1 =W 2 / (1-N%); where: W 1 : raw material consumption in wet state, g; W 2 : dry raw material usage, g; N: wet raw material water content; the activity of the zirconium powder is greater than 90%, and the zirconium powder raw material water content is 9%;

[0041](2) Weigh the loose asbestos paper, soak it in distilled water for 8.5 hours, then stir it with a stirrer for 3.5 min...

Embodiment 2

[0045] A method for improving the safety of ignition paper preparation, comprising the following steps:

[0046] (1) use moisture tester to measure the water content of zirconium powder, barium chloride and potassium chromate, according to the difference of water content of zirconium powder, barium chloride and potassium chromate, calculate the dry weight of raw material respectively by formula, and chlorine Barium chloride and potassium chromate are dissolved in distilled water respectively, obtain barium chloride solution and potassium chromate solution; Described formula is: W 1 (1-N%)=W 2 or W 1 =W 2 / (1-N%); where: W 1 : raw material consumption in wet state, g; W 2 : dry raw material usage, g; N: wet raw material water content; the activity of the zirconium powder is greater than 90%, and the zirconium powder raw material water content is 15%;

[0047] (2) Weigh the loose asbestos paper, soak it with distilled water for 12 hours, then stir the loose asbestos paper i...

Embodiment 3

[0051] A method for improving the safety of ignition paper preparation, comprising the following steps:

[0052] (1) use moisture tester to measure the water content of zirconium powder, barium chloride and potassium chromate, according to the difference of water content of zirconium powder, barium chloride and potassium chromate, calculate the dry weight of raw material respectively by formula, and chlorine Barium chloride and potassium chromate are dissolved in distilled water respectively, obtain barium chloride solution and potassium chromate solution; Described formula is: W 1 (1-N%)=W 2 or W 1 =W 2 / (1-N%); where: W 1 : raw material consumption in wet state, g; W 2 : dry raw material usage, g; N: wet raw material water content; the activity of the zirconium powder is greater than 90%, and the zirconium powder raw material water content is 10%;

[0053] (2) Weigh the loose asbestos paper, soak it with distilled water for 9 hours, then stir it with a stirrer for 4 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com