Atomizing nozzle structure of desuperheating valve

A technology of atomizing nozzle and desuperheating valve, applied in the direction of injection device, injection device, etc., can solve the problems of complicated installation of venturi, influence of desuperheating system pipeline, increase of pipeline difficulty, etc., so as to shorten production cycle and reduce production cost. , The effect of easy and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

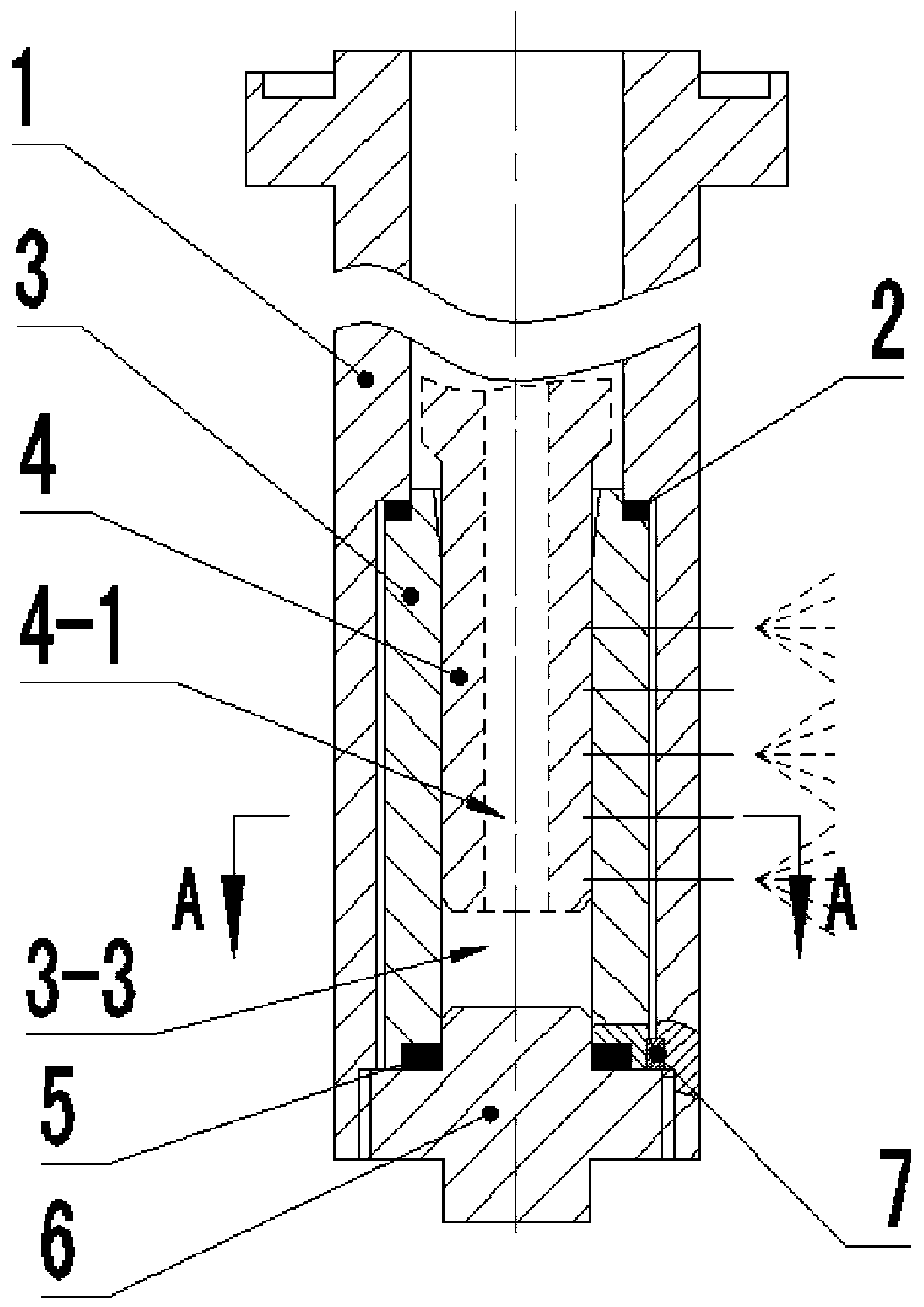

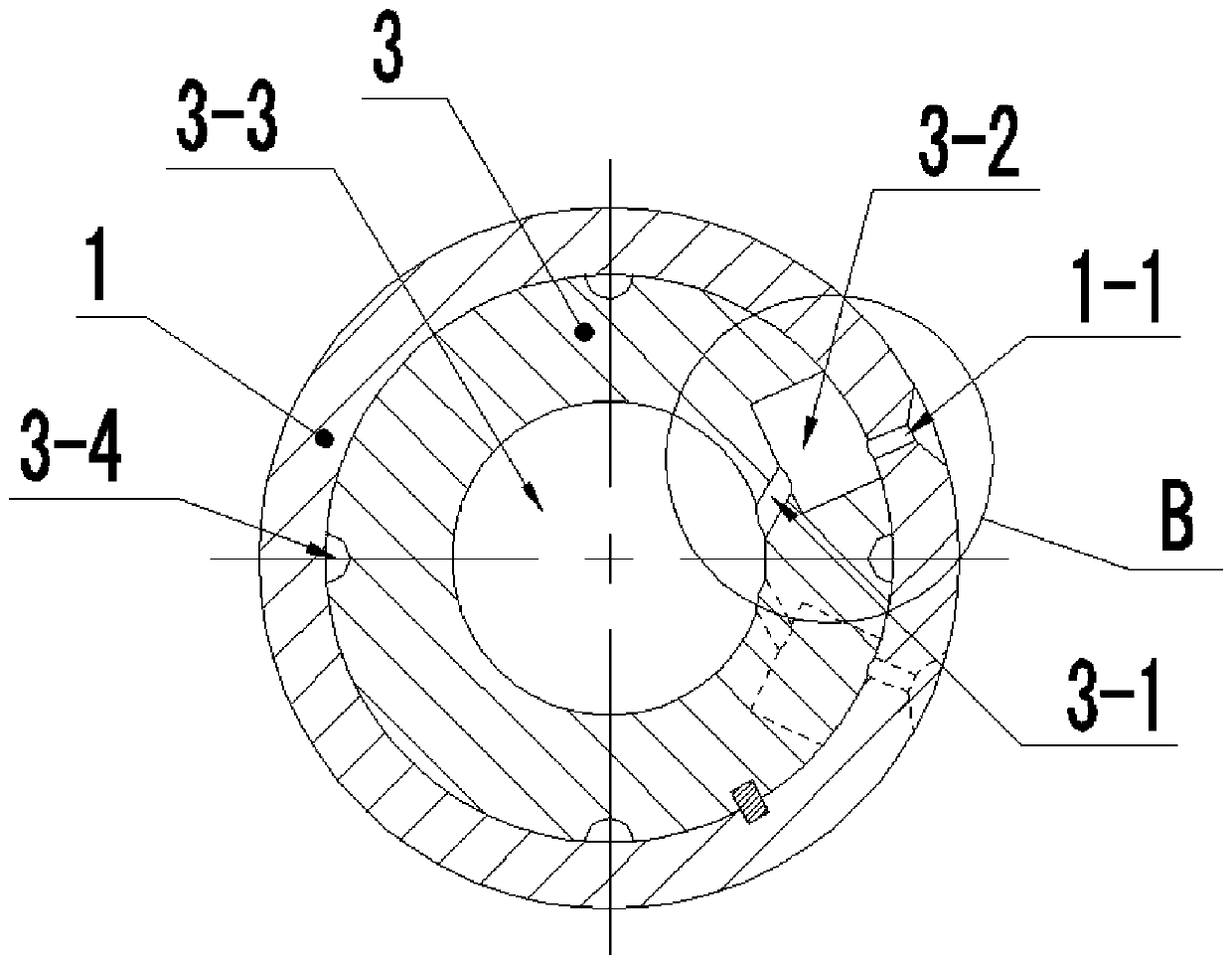

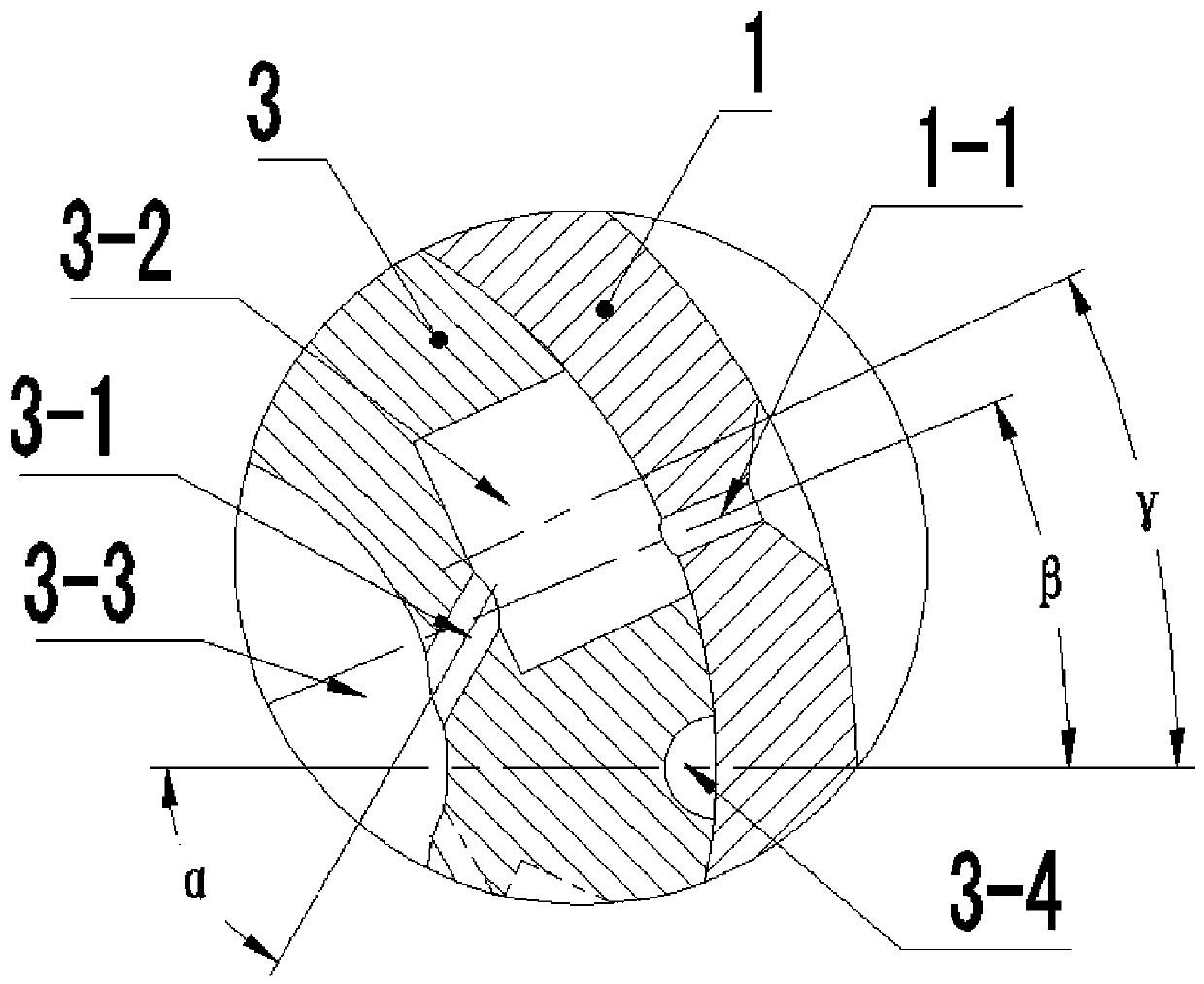

[0033] see Figure 1 to Figure 8, an atomizing nozzle structure of a temperature reducing valve, comprising a valve core 4 and a sleeve type atomizing nozzle, the axis of the valve core 4 is provided with a water hole 4-1, the valve core 4 and the valve of the temperature reducing valve Rod 8 is connected and fixed. The sleeve-type atomizing nozzle includes an outer sleeve 1 and an inner sleeve 3. The outer sleeve 1 is provided with a stepped hole 1-2 at the axis, and the inner sleeve 3 is assembled in the stepped hole 1-2 of the outer sleeve 1. The large-diameter hole of 2 has a clearance fit with the outer sleeve 1, and the clearance fit is a clearance fit with a high tolerance level. And the inner sleeve 3 is circumferentially positioned with the outer sleeve 1 through the key 7 , and the inner sleeve 3 and the outer sleeve 1 are correspondingly provided with key grooves for installing the key 7 . The upper end of the inner sleeve 3 is axially limited by the shoulder 1-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com