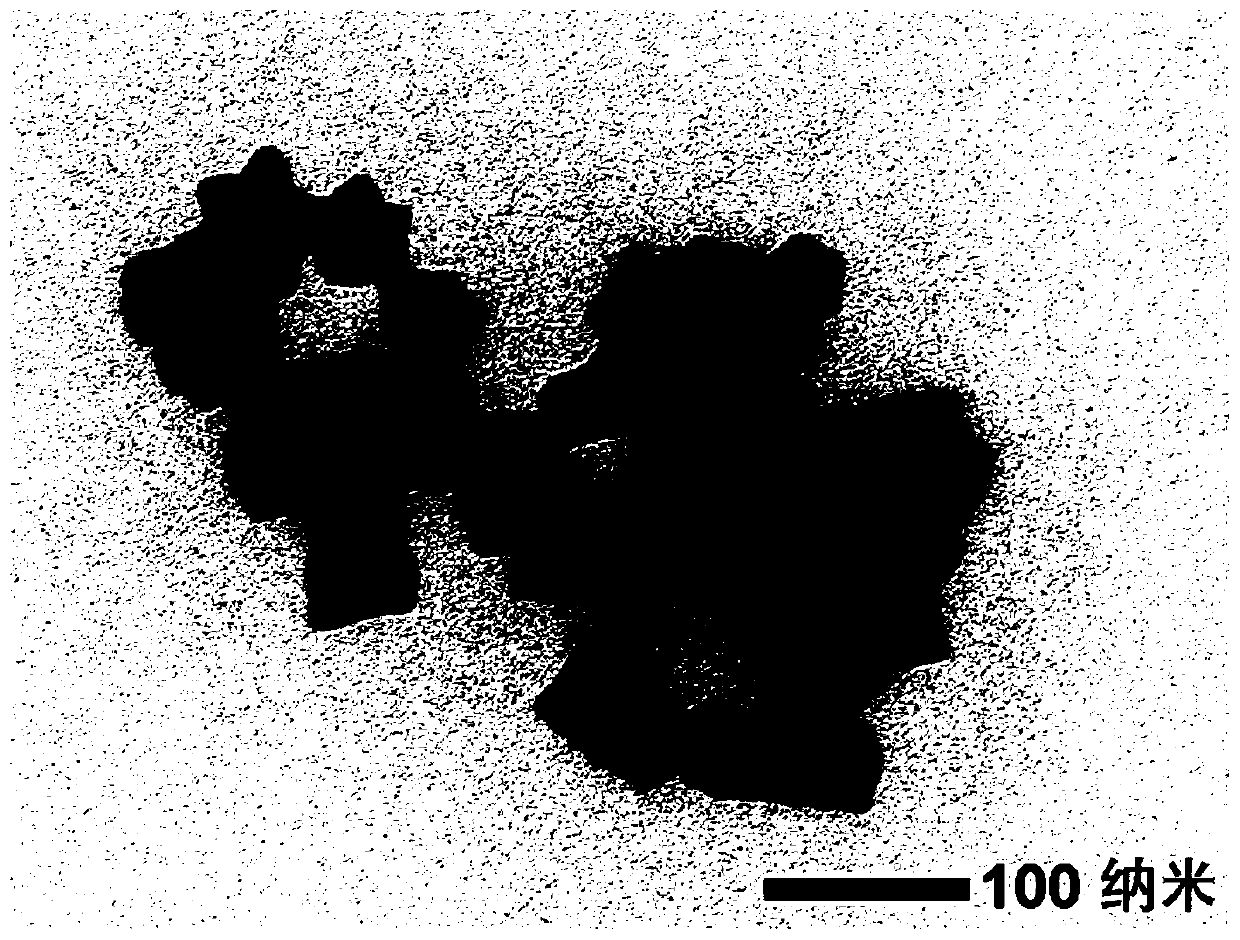

Preparation method of concave type hollow platinum-palladium nanocrystal, concave type hollow platinum-palladium nanocrystal and application thereof

A nanocrystal, concave technology, applied in nanotechnology, microsphere preparation, chemical instruments and methods, etc., can solve problems such as lack of mature technology, and achieve the effect of reducing dosage, improving catalytic activity, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A method for preparing concave hollow platinum-palladium nanocrystals specifically includes the following steps:

[0074] a) The palladium source compound is mixed with a surfactant, a reducing agent, a first solvent and a surface coating agent and reacted at 180°C for 100 minutes, then centrifuged and washed to obtain palladium nanocrystals; palladium source compound, surfactant , The weight ratio of reducing agent, first solvent and surface coating agent is 1:1:1:150:1;

[0075] b) Disperse the palladium nanocrystals in the first solvent, add the palladium source compound, surfactant, reducing agent and surface coating agent to mix, and react at 180℃ for 100 minutes to prepare concave palladium nanocrystals; palladium nanocrystals , The weight ratio of the first solvent, the palladium source compound, the surfactant, the reducing agent, and the surface coating agent is 1:150:1:1:1:1;

[0076] c) Disperse the recessed palladium nanocrystals in the second solvent, add surfact...

Embodiment 2

[0081] A method for preparing concave hollow platinum-palladium nanocrystals specifically includes the following steps:

[0082] a) The palladium source compound is mixed with surfactant, reducing agent, first solvent and surface coating agent and reacted at 30°C for 180 minutes, then centrifuged and washed to prepare palladium nanocrystals; palladium source compound, surfactant , The weight ratio of reducing agent, first solvent and surface coating agent is 1:5:2:200:3;

[0083] b) Disperse the palladium nanocrystals in the first solvent, add the palladium source compound, surfactant, reducing agent and surface coating agent to mix and react at 30°C for 180 minutes to prepare concave palladium nanocrystals; palladium nanocrystals , The weight ratio of the first solvent, the palladium source compound, the surfactant, the reducing agent, and the surface coating agent is 2:200:1:5:2:3;

[0084] c) Disperse the recessed palladium nanocrystals in the second solvent, add surfactant, plat...

Embodiment 3

[0089] A method for preparing concave hollow platinum-palladium nanocrystals specifically includes the following steps:

[0090] a) The palladium source compound is mixed with a surfactant, a reducing agent, a first solvent and a surface coating agent and reacted at 60°C for 160 minutes, then centrifuged and washed to obtain palladium nanocrystals; palladium source compound, surfactant , The weight ratio of reducing agent, first solvent and surface coating agent is 1:7:2:250:2;

[0091] b) Disperse the palladium nanocrystals in the first solvent, add the palladium source compound, surfactant, reducing agent and surface coating agent to mix and react at 60°C for 160 minutes to prepare concave palladium nanocrystals; palladium nanocrystals , The weight ratio of the first solvent, the palladium source compound, the surfactant, the reducing agent, and the surface coating agent is 2.5:250:1:8:2.5:4;

[0092] c) Disperse the recessed palladium nanocrystals in the second solvent, add surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com