Axial radial HPPO fixed bed reactor

A fixed-bed reactor, axial-radial technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of uneven catalyst filling, uneven reaction temperature, inflexible temperature control means, etc. Small, high space utilization, easy to enlarge the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

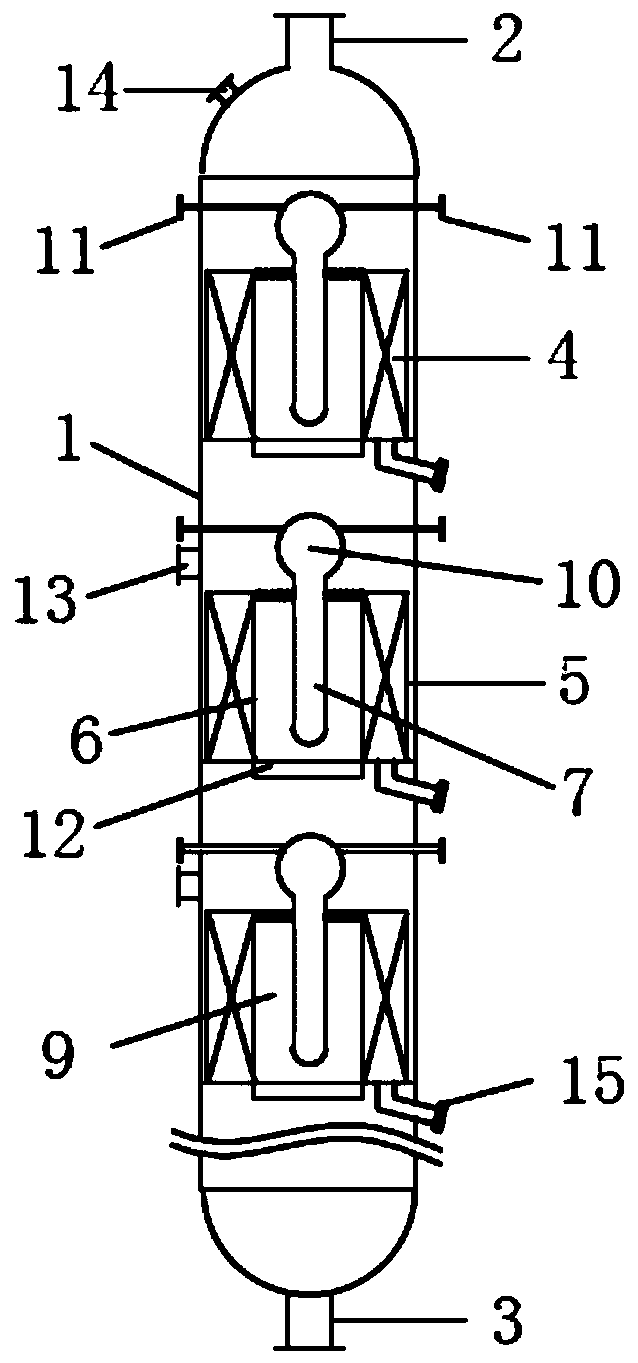

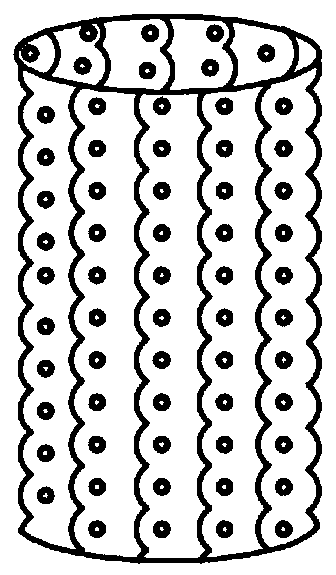

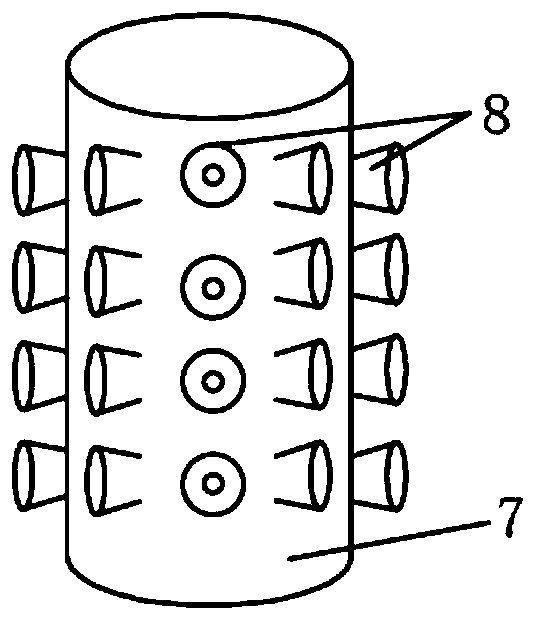

[0038] Such as Figure 1 to Figure 3 The shown axis is a radial HPPO fixed bed reactor, which includes an upper head, a lower head, a shell 1 and the like. The upper head has a material inlet pipe 2 communicating with its interior, and the lower head of the shell 1 has a material outlet pipe 3 communicating with its interior. There are several radial flow catalyst beds 4 in the shell 1, and each radial flow catalyst bed 4 is provided with an outer cylinder 5 and an inner cylinder 6. The center of the inner cylinder 6 is provided with a central pipe 7, and its surface is provided with regularly arranged conical nozzles 8. The hot fluid at the outlet of the inner cylinder 6 is heated in the central heat exchange cylinder 9 with the cold fluid ejected from the central pipe 7. The exchange not only takes away the heat released by the reaction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com