Apparatus for bending glass panels

A glass plate, bending technology, applied in glass manufacturing equipment, glass transportation equipment, glass forming, etc., can solve unused problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

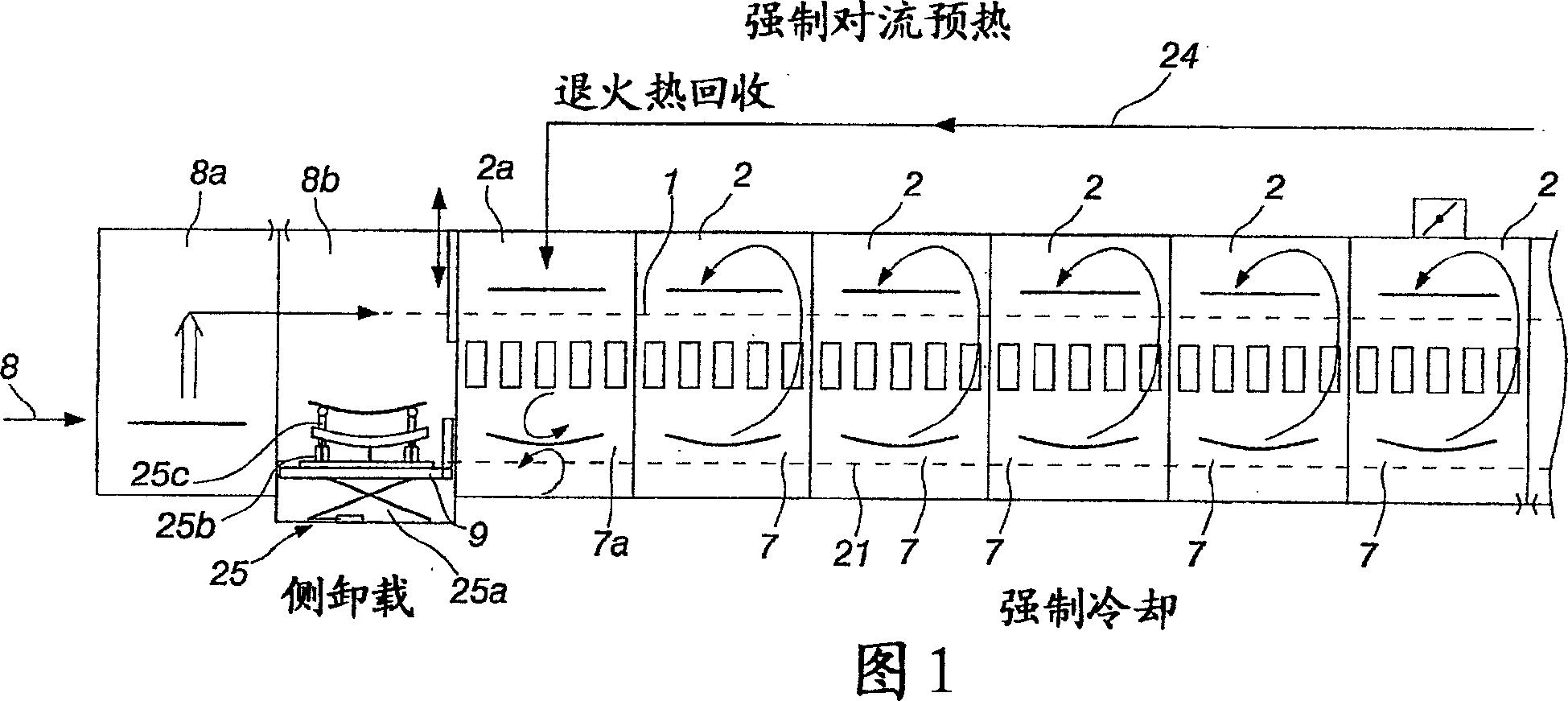

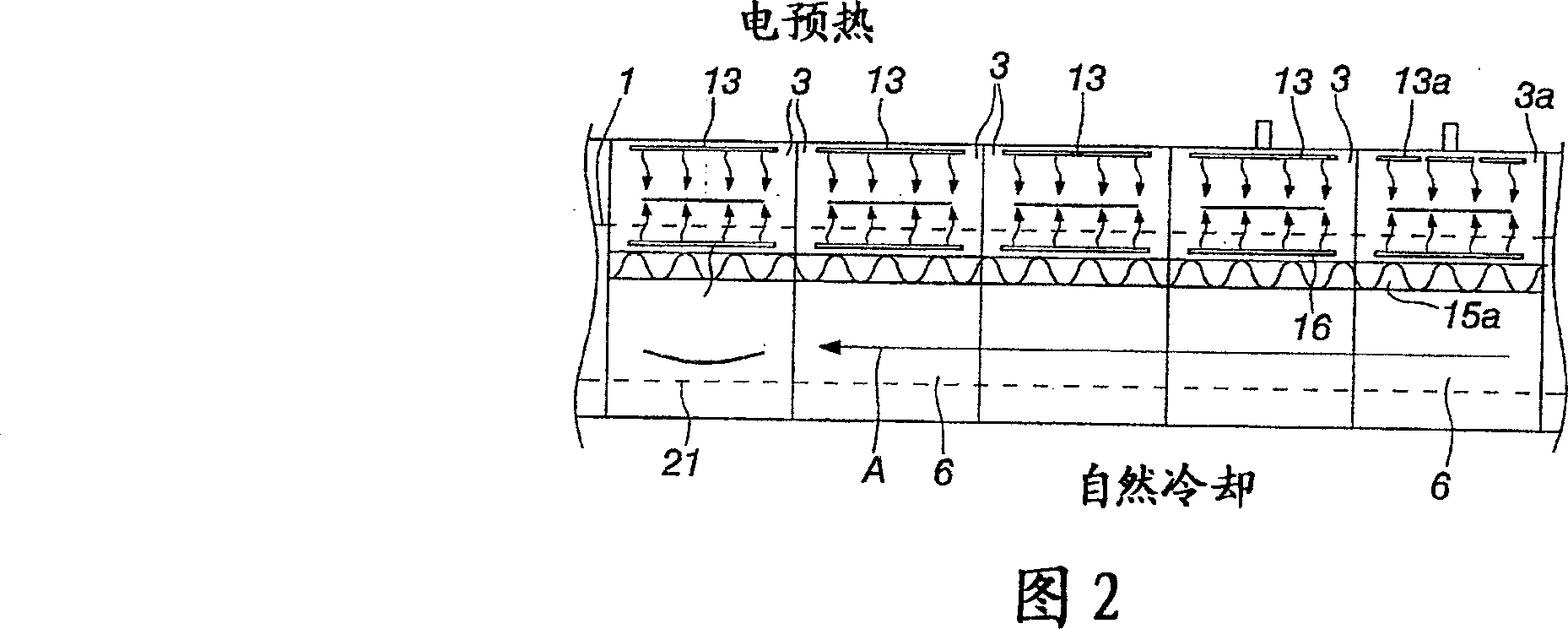

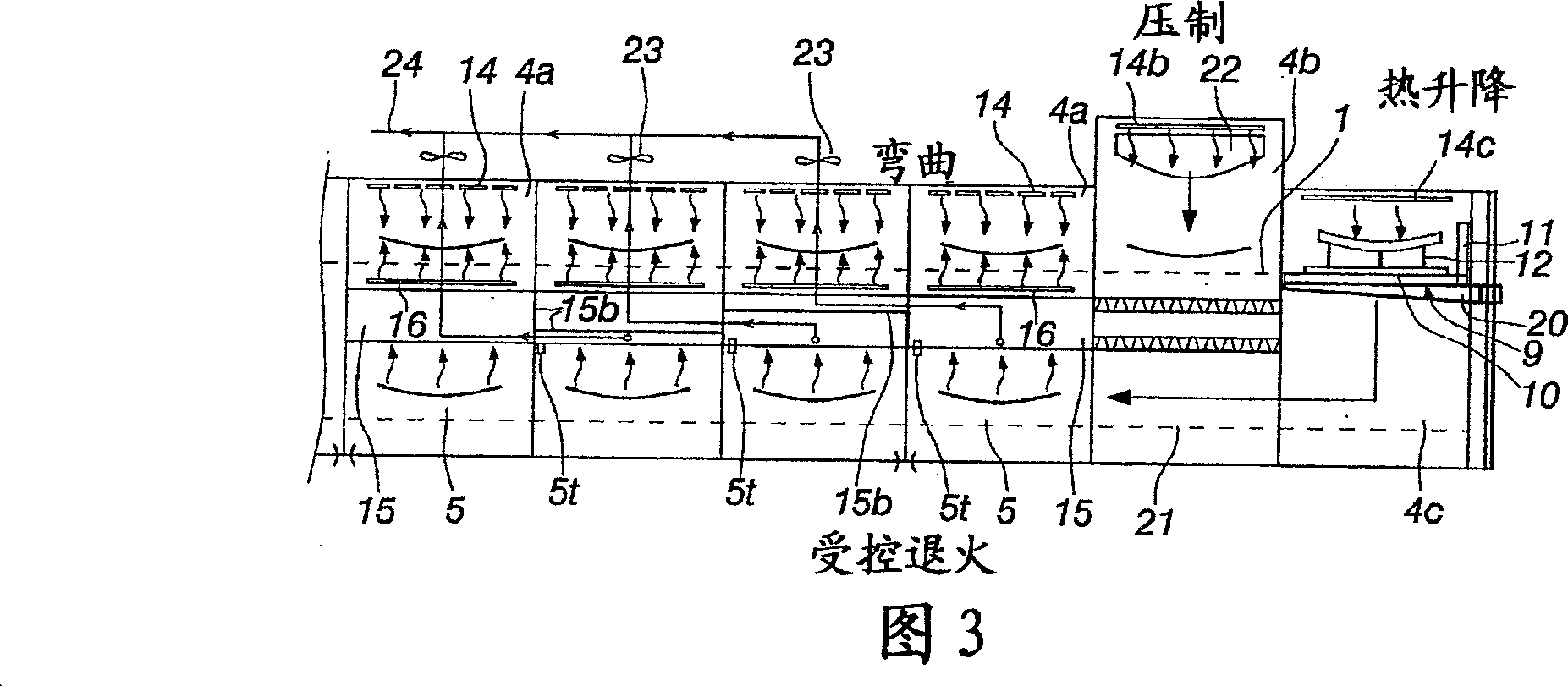

[0023] The equipment shown in Figures 1-3 includes an upper mold carriage guide rail 1 with a continuous mold carriage 9, the front wall or rear wall 11 of the mold carriage connects the continuous preheating chambers 2, 3 and several continuous bending chambers 4a, 4b are spaced apart from each other. The mold carrier is suitable for intermittent delivery to the last bending chamber 4b, and a liftable male mold 22 is arranged on the top plate of the bending chamber. The lower mold carriage guide rail 21 carries the continuous mold carriage 9 located below the mold carriage of the upper guide rail 1 . The mold truck 9 of the lower mold truck rail 21 has a rear or front wall 11 separating successive cooling chambers 5, 6 and 7 from each other. The mold carriage 9 of the lower guide rail 21 is suitable for intermittent conveyance along the direction opposite to the conveying direction of the mold carriage located on the upper mold carriage guide rail.

[0024] Each mold truck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com