Flue water reverse circulation recovery heat energy furnace

A technology of recycling and flue, which is applied to water heaters/stoves, household heating, household heating, etc., can solve the problems of large water heating area, waste of energy, unsuitable for instant hot water, etc., to achieve Reasonable heating and effective use of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

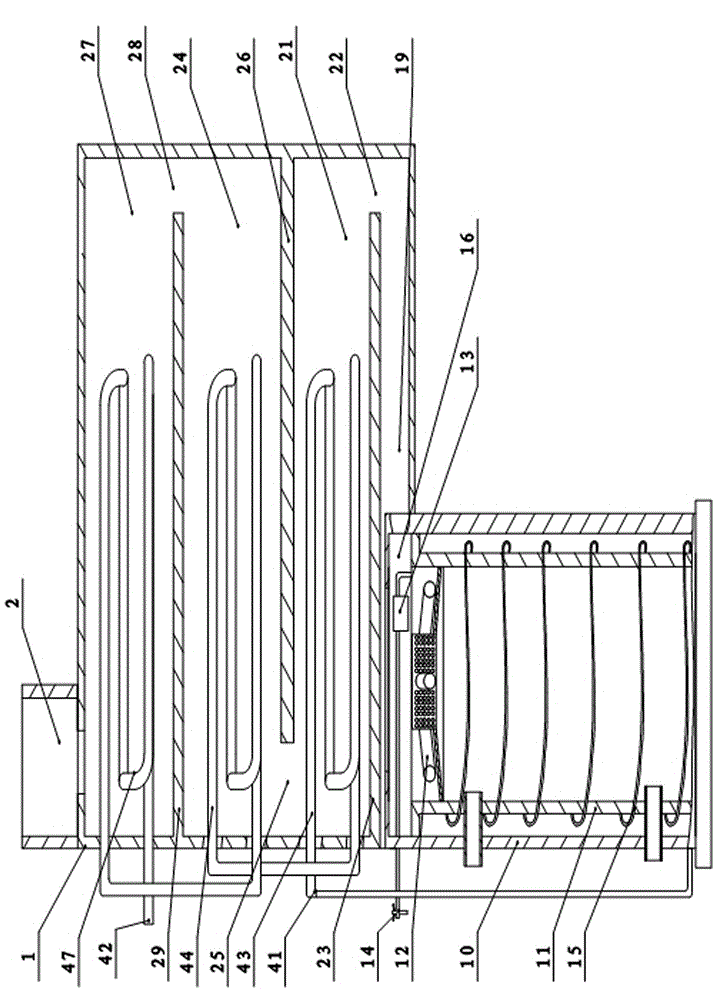

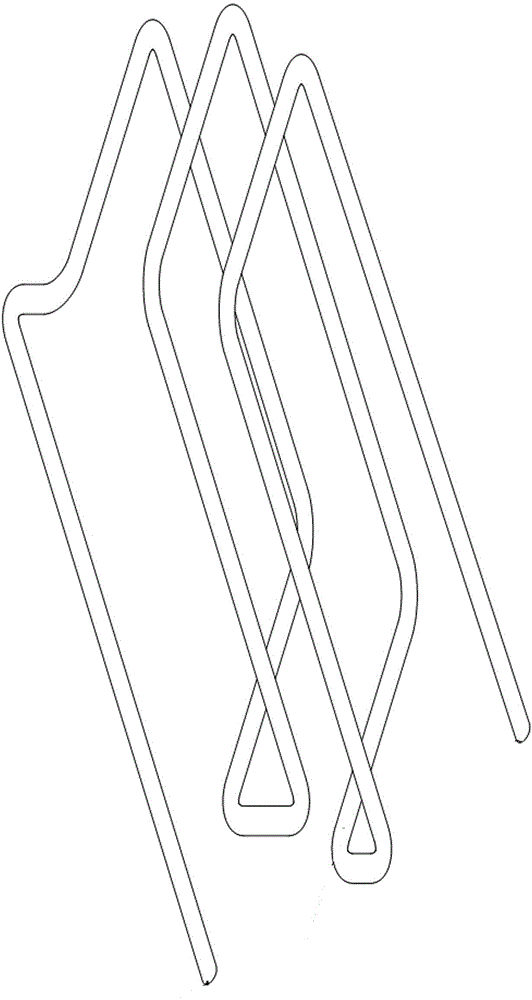

[0028] Embodiment 1: as figure 1 As shown: this embodiment 1 includes a heating furnace, a heating box 1 connected to the flue of the heating furnace, and a chimney 2 connected to the heating box 1; a heating chamber is arranged in the heating box 1, and a detour water pipe 4 is arranged in the heating chamber ; Detour water pipe 4 is a detour setting. The flue of the heating furnace is arranged circuitously in the heating box 1, and its path is a continuous broken line. The detour water pipe 4 includes a first detour pipe 43, a second detour pipe 44 and a third detour pipe 47; a partition A23 and a partition C29 are arranged on one side of the heating box 1, and on the other side of the heating box 1 A partition B26 is arranged on the top; the partition A23 is arranged below the partition B26, and the partition C29 is arranged above the partition B26; between the partition A23 and the bottom plate of the heating box 1 is a heat inlet channel 19; between the partition A23 Be...

Embodiment 2

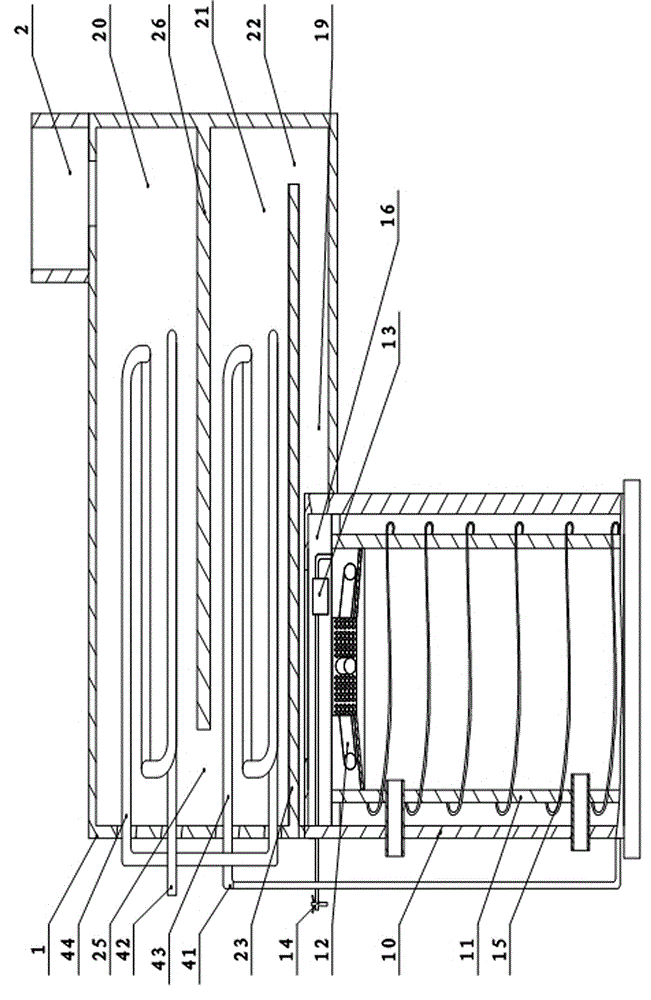

[0032] Embodiment 2: as figure 2 As shown: this embodiment 2 includes a heating furnace, a heating box 1 communicating with the flue of the heating furnace, and a chimney 2 communicating with the heating box 1; a heating chamber is arranged in the heating box 1, and a circuitous water pipe 4 is arranged in the heating chamber ; Detour water pipe 4 is a detour setting. The flue of the heating furnace is arranged in a detour in the heating box 1 .

[0033] The detour water pipe 4 comprises a first detour pipe 43 and a second detour pipe 44; a partition A23 is arranged on one side plate of the heating box 1; a partition B26 is provided on the other side board of the heating box 1; The heating chamber A21 is formed between A23, the partition B26 and the two side plates of the heating box 1; the heating chamber b20 is formed between the partition B26, the top plate of the heating box 1 and the two side plates of the heating box 1; between the partition A23 and the corresponding Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com