A kind of production method of fabric substrate in architectural space membrane structure

A technology of architectural space and production methods, applied in the direction of instruments, geometric CAD, design optimization/simulation, etc., can solve problems such as large amount of calculation, low efficiency, and inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The application will be further described in detail below in conjunction with the accompanying drawings.

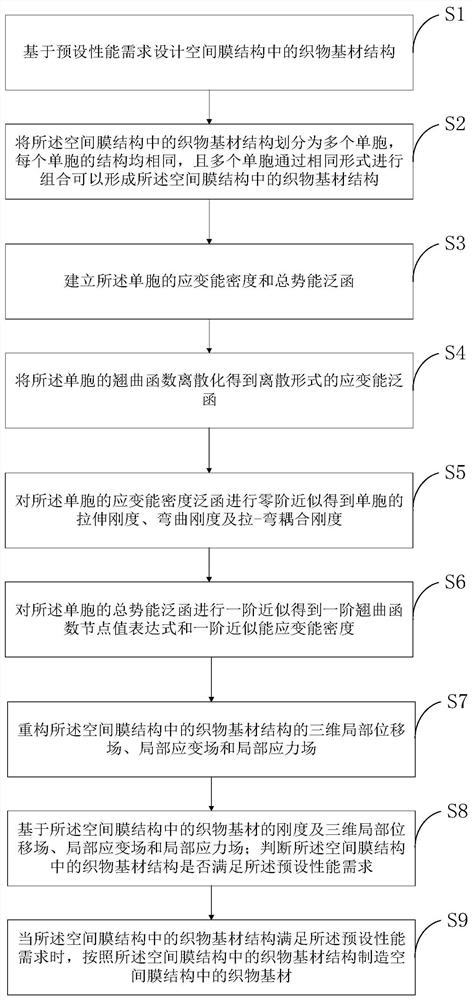

[0101] like figure 1 Shown, the present invention discloses a kind of production method of fabric substrate in building space membrane structure, comprises the following steps:

[0102] S1. Design the fabric substrate structure in the space membrane structure based on preset performance requirements;

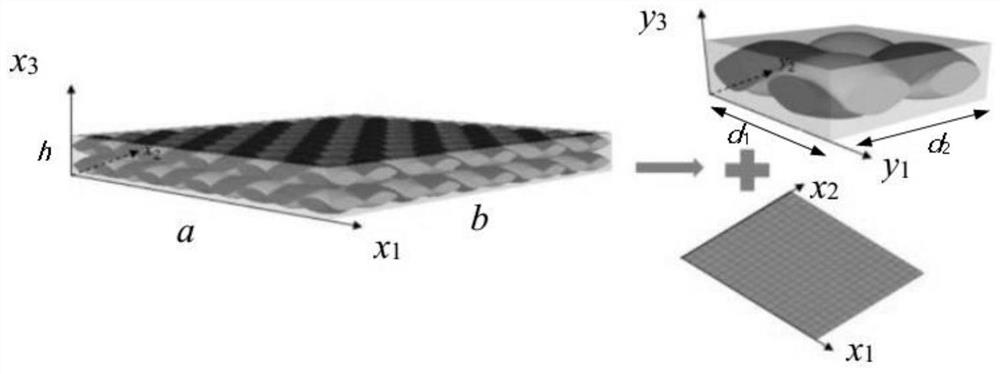

[0103] S2, such as image 3 As shown, the fabric substrate structure in the space membrane structure is divided into a plurality of unit cells, each unit cell has the same structure, and multiple unit cells can be combined in the same form to form the space membrane structure. fabric substrate structure;

[0104] S3, establishing the strain energy density and the total potential energy functional of the unit cell;

[0105] S4. Discretizing the warping function of the unit cell to obtain a discrete strain energy functional;

[0106] S5, performing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com